Views: 206 Author: Reshine Publish Time: 2023-07-05 Origin: Site

TFT LCD monitors are susceptible to glare and reflection from direct sunlight or bright applications. In almost all TFT LCDs, there is an air gap between the TFT panel and the cover lens. Having an air gap causes repeat refraction between each component level of the display in high-brightness installations. Reducing the reflection inside these components with optical bonding gives greater contrast and makes the screen more viewable in outdoor or highly bright conditions without the need to increase the brightness of the screen itself.

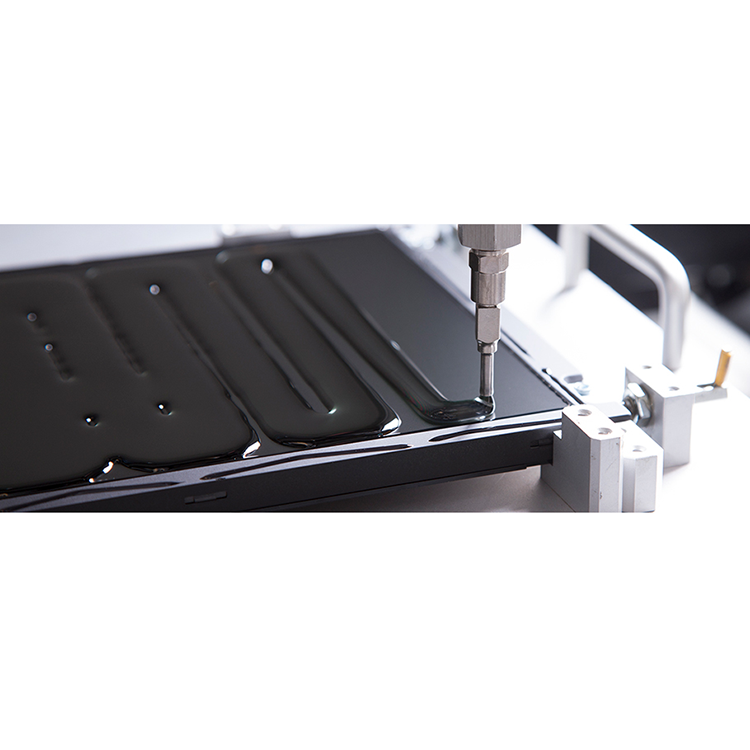

Optical bonding is a process where a layer of resin is applied between the glass or touchscreen and the TFT LCD or TFT panel of a monitor, bonding them to make a solid laminate with no gaps or pockets of air. When choosing a screen for any project, you should evaluate the environment and operating conditions the screen will have to endure. Industrial-grade screens and panel PCs are rugged, with all types of features available to withstand any type of application. One such feature available to consider is optical bonding.

1. The display from a non-optically bonded monitor is created by the light of the LCD reflecting through the gap and then the outer glass of the screen. The light is interrupted and bends when it passes through the gap and glass of the screen and some of the light is reflected to the LCD module, this is called refraction. This refraction through the layers impairs the intensity and clarity of the end image and thus lowers brightness and readability. By bonding the LCD module and glass together you remove the interruptions and chances for the light to be reflected. More light gets through to the surface of the screen and therefore the image is brighter.

2. The same principle is applied when an external source of light hits the screen. With a non-bonded screen, the gap between the glass and LCD module creates opportunities for refraction which bounces external light back off the screen to the viewer as glare. When bonded together the light passes through the bonded layers and is absorbed somewhat into the screen. Optical bonding is therefore important in making screens sunlight readable.

3. Optical bonding makes screens more physically durable

The additional resin layer in optical bonding absorbs shock. This provides high durability for use in public access areas, factories, or other harsh environments.

4. The most obvious benefit to adding a resin bonding layer between the glass and LCD module is that it physically prevents dust and liquid ingress from getting between the two. The quality of manufacturing means that dust and water aren’t a big problem for screens in standard environments. What can be a problem however is condensation getting between the glass and LCD panel in environments with wide temperature ranges or fluctuating humidity. Condensation can cause screens to become foggy from moisture that penetrates the air gap. Again, the physical filling of the gap prevents this problem from arising. Optical bonding should therefore be considered for any outdoor application as well as indoor applications where consistent temperatures aren’t maintained.

5. A touch monitor with optical bonding maintains a more accurate touch response because the pressure is maintained through the substrate, rather than being delayed by a gap.Assured Systems are partnered with designers and manufacturers of industrial displays with optically bonded touch screens request, their displays or touchscreen displays can be optically bonded to remove the air gap inside the screen. If you require an optically bonded display or optically bonded panel PC please get in touch with Assured Systems.

Optical Bonding lends itself perfectly to a range of different industries, typically those that require higher-performing displays. Optical Bonding is suited to industries that tend to use rugged displays in high-reliability environments or industries where displays need to be seen in high ambient light conditions. The process of Optical Bonding is particularly well-suited and much more effective when applied to devices that operate outdoors or in heavily lighted environments.

Typically, Optical Bonding is used in and popular among the military, marine, medical, transportation, and retail sectors.

Can You Improve User Experience with Resistive Touch Screens?

How Do You Calibrate and Maintain Your Resistive Touch Screen for Accurate Results?

Touchscreen technology for electric vehicle charging stations

How To Find The Best Touchscreen Display Solution for Your Smart Home System?

Revolutionizing In-Car Infotainment: The Power of Advanced Touchscreen Displays

How we achieve the sleek All-Black Touchscreen display design