Views: 222 Author: Wendy Publish Time: 2025-12-21 Origin: Site

Content Menu

● Why China Leads in Custom Capacitive Touch Screen Manufacturing

● Typical Structures and Technologies in Custom Capacitive Touch Screen Design

● Applications of Custom Capacitive Touch Screen Solutions

● Top 10 Custom Capacitive Touch Screen Manufacturers in China

>> 1. New Vision Display (Shenzhen) Co., Ltd.

>> 2. Shenzhen Touch Think Intelligence Co., Ltd.

>> 3. Shenzhen Huaxin Display Control Technology Co., Ltd. (HXXK TOUCH)

>> 5. Dongguan Yunshang Electronic Technology Co., Ltd. (CloudTop)

>> 9. TouchWo

>> 10. DOPO Tech Group Limited

● Key Technical Parameters in Custom Capacitive Touch Screen Projects

● Environmental and Reliability Considerations

● How to Select a Custom Capacitive Touch Screen Supplier in China

● Typical OEM / ODM Workflow for Custom Capacitive Touch Screen

● Example Focus Table for Selected Suppliers

● FAQ About Custom Capacitive Touch Screen

>> 1. What is a Custom Capacitive Touch Screen?

>> 2. What information should buyers prepare before requesting a Custom Capacitive Touch Screen?

>> 3. How long does development normally take for a Custom Capacitive Touch Screen?

>> 4. What advantages does a Custom Capacitive Touch Screen offer compared with standard products?

>> 5. Can Custom Capacitive Touch Screen panels support glove and water operation?

China has become a global hub for Custom Capacitive Touch Screen solutions, supplying industrial, medical, automotive, retail, and smart device projects around the world. For overseas OEMs and system integrators, choosing the right Custom Capacitive Touch Screen partner in China is essential for long‑term reliability, cost control, and flexible customization.[1]To help buyers make informed decisions, this guide introduces ten representative Custom Capacitive Touch Screen manufacturers in China, explains key technical considerations, and shows how to cooperate efficiently on OEM and ODM projects. Throughout the article, the keyword Custom Capacitive Touch Screen is emphasized while keeping the content natural and easy to read.[1]

China has developed complete supply chains for glass, ITO film, controller ICs, LCD and TFT modules, and optical bonding, which strongly supports Custom Capacitive Touch Screen projects. This vertical integration allows Chinese factories to offer competitive prices and shorter lead times for both standard and custom PCAP touch modules.[2]Many Chinese manufacturers have invested in R&D, clean‑room production, and reliability testing labs, enabling them to develop industrial‑grade Custom Capacitive Touch Screen solutions for harsh environments. As a result, China now serves customers in automation, banking, transportation, medical devices, and outdoor signage with tailored capacitive touch products.[2][1]

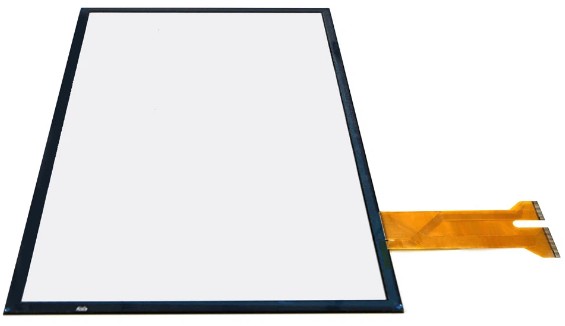

Most industrial Custom Capacitive Touch Screen products are based on projected capacitive (PCAP) technology, which uses a matrix of electrodes to detect changes in capacitance caused by a finger or conductive stylus. This approach enables multi‑touch, fast response, and high transparency, making it ideal for modern human–machine interface devices.[3]In terms of stack‑up, G+G (glass + glass) is widely used in Custom Capacitive Touch Screen projects because it offers better dimensional stability, optical performance, and scratch resistance than film structures. For cost‑sensitive or ultra‑thin devices, G+F or G+FF structures may be selected, but many industrial customers still prefer G+G in their Custom Capacitive Touch Screen modules.[2]

Custom Capacitive Touch Screen technology is widely used across industrial, commercial, and consumer markets in China and overseas. By customizing the cover glass, electronics, and mechanical integration, manufacturers can adapt one core technology to many different application scenarios.[1][2]Typical application fields include:- Industrial HMI: Machine tools, packaging lines, robotics, and process control systems use Custom Capacitive Touch Screen interfaces for intuitive operation and data visualization.[2]- Medical equipment: Patient monitors, diagnostic instruments, and lab analyzers require high‑clarity Custom Capacitive Touch Screen panels with chemical resistance and easy cleaning.[1]- Transportation: In‑vehicle displays, ticketing machines, and station kiosks use rugged Custom Capacitive Touch Screen units that withstand vibration, temperature variation, and frequent use.[1]- Retail and self‑service: POS terminals, vending machines, and information kiosks rely on Custom Capacitive Touch Screen fronts that support fast, accurate touch and brand‑specific design.[4]- Smart home and appliances: Ovens, washing machines, and smart thermostats integrate compact Custom Capacitive Touch Screen panels as replacements for traditional switches and knobs.[1]For manufacturers in the abrasives and refractory sector, deploying Custom Capacitive Touch Screen HMIs in grinding, cutting, and inspection equipment can support digital process control and real‑time data collection.[2]

The following ten companies represent different capabilities within China's Custom Capacitive Touch Screen ecosystem, from industrial panels to large‑format interactive displays.[1]

New Vision Display (NVD) specializes in custom touchscreen display solutions, including PCAP sensors and Custom Capacitive Touch Screen modules for automotive, medical, and industrial use. Its PRECI‑Touch line is designed for demanding environments where stable performance and precise control are required over long lifecycles.[1]Key characteristics:- Focus: PCAP touch sensors, Custom Capacitive Touch Screen modules, integrated LCD + touch solutions.[1]- Industries: Automotive clusters, medical monitors, industrial control panels, white goods.[1]- Advantages: Strong engineering support, customized mechanics, and robust validation capabilities for high‑reliability applications.[1]NVD is well suited to OEMs that need fully customized Capacitive Touch Screen assemblies with automotive‑grade or medical‑grade performance.[1]

Touch Think focuses on industrial monitors and panel PCs that integrate Custom Capacitive Touch Screen fronts with industrial LCDs and rugged enclosures. The company provides both standard products and deeply customized solutions tailored to factory and field environments.[1]Key characteristics:- Focus: Industrial displays, panel PCs, and embedded systems with Custom Capacitive Touch Screen interfaces.[1]- Industries: Factory automation, transportation, energy, logistics, outdoor terminals.[1]- Advantages: Wide‑temperature operation, IP‑rated designs, and long‑term supply support for industrial projects.[1]Touch Think is ideal for buyers who want complete HMI systems rather than only a bare Custom Capacitive Touch Screen panel.[1]

HXXK TOUCH provides a broad range of custom touch solutions, including multi‑touch capacitive panels for varied industries. Its Custom Capacitive Touch Screen portfolio includes different shapes, sizes, and integration options to suit unique product designs.[1]Key characteristics:- Focus: Custom Capacitive Touch Screen sensors and integrated touch modules.[1]- Industries: Industrial equipment, kiosks, medical terminals, vending machines.[1]- Advantages: Flexible mechanical design, multiple touch technologies, and support for special shapes and mounting structures.[1]This supplier is suitable for customers who need distinctive industrial designs or non‑standard form factors for their Custom Capacitive Touch Screen fronts.[1]

Panamich Electronic focuses on innovative touch display systems and offers large‑format Custom Capacitive Touch Screen solutions. The company can integrate glass, touch sensors, displays, and enclosures into turnkey interactive products.[1]Key characteristics:- Focus: Large‑size touch displays and custom interactive solutions based on Custom Capacitive Touch Screen technology.[1]- Industries: Digital signage, corporate conference systems, interactive education, retail.[1]- Advantages: Expertise in large formats, multi‑touch performance, and system‑level integration for public spaces.[1]Panamich is a good choice for projects requiring large Custom Capacitive Touch Screen surfaces, such as interactive walls or digital wayfinding kiosks.[1]

CloudTop offers custom projected capacitive touch display modules and touchscreen components covering a wide size range. Its Custom Capacitive Touch Screen products are commonly integrated into industrial, medical, and smart home devices.[1]Key characteristics:- Focus: PCAP modules and Custom Capacitive Touch Screen assemblies combining sensor, cover glass, and FPC.[1]- Industries: Industrial controllers, medical devices, household appliances, smart terminals.[1]- Advantages: Broad size coverage, flexible customization, and experience with multi‑industry requirements.[1]CloudTop is well suited to brands that need both standard PCAP options and fully customized Capacitive Touch Screen solutions for different product lines.[1]

FINELINK Photoelectric focuses on R&D and manufacturing of capacitive touch panels, offering many custom options for different industries. Its Custom Capacitive Touch Screen solutions are used in outdoor terminals, banking machines, educational devices, and smart home systems.[1]Key characteristics:- Focus: Touch panels and Custom Capacitive Touch Screen solutions, including outdoor‑capable PCAP products.[1]- Industries: Outdoor kiosks, ATMs, interactive education boards, smart appliances.[1]- Advantages: Rich application experience and customization for environmental challenges like sunlight, vandalism, and heavy public use.[1]FINELINK is a strong candidate when a Custom Capacitive Touch Screen must operate in demanding public or semi‑outdoor locations.[1]

Touch‑China is a well‑known touch screen manufacturer that supplies both resistive and capacitive panels, with extensive customization capabilities. It has independently developed projected capacitive touch solutions and can provide fully customized designs for many application fields.[5]Key characteristics:- Focus: Custom Capacitive Touch Screen and resistive touch panels, plus integrated touch‑display modules.[5]- Industries: Automotive, industrial equipment, financial terminals, education, retail displays.[5]- Advantages: Mature product lines, broad industry coverage, and flexible OEM and ODM cooperation models.[5]Touch‑China is a versatile partner for customers who may require multiple touch technologies alongside Custom Capacitive Touch Screen solutions.[5]

BUNSUN Display positions itself as an industrial‑grade PCAP manufacturer, providing Custom Capacitive Touch Screen products and standard modules. Its G+G structure and focus on industrial markets give it an advantage where durability and EMC performance are critical.[2]Key characteristics:- Focus: Industrial‑grade PCAP and Custom Capacitive Touch Screen solutions in G+G structure.[2]- Sizes: Approximately 3.5 to 55 inches with support for multiple touch points.[2]- Industries: Industrial automation, medical devices, financial instruments, transportation systems.[2]- Advantages: High surface hardness, good light transmission, and fast response tailored for robust environments.[2]BUNSUN is ideal for rugged Custom Capacitive Touch Screen projects requiring glove operation, water tolerance, and strong anti‑interference design.[2]

TouchWo manufactures touch panels, kiosks, and complete interactive systems and integrates in‑house metal processing with touch production. It can provide not only Custom Capacitive Touch Screen panels but also complete housings and finished terminals.[4]Key characteristics:- Focus: Touch panels, kiosks, and open‑frame monitors based on Custom Capacitive Touch Screen fronts.[4]- Industries: Self‑service kiosks, retail terminals, industrial control stations.[4]- Advantages: One‑stop manufacturing from sheet metal to touch panel, enabling fast OEM and ODM customization.[4]TouchWo is suitable when the customer wants to outsource the full device, including enclosure, display, and Custom Capacitive Touch Screen interface.[4]

DOPO Tech specializes in projected capacitive touch panels and Custom Capacitive Touch Screen products for different sizes and applications. It focuses on PCAP technology and offers OEM and ODM services to international customers.[6]Key characteristics:- Focus: Projected capacitive panels and Custom Capacitive Touch Screen customization.[6]- Industries: Industrial equipment, commercial terminals, consumer electronics.[6]- Advantages: Concentration on PCAP technology and flexible cooperation for tailored designs.[6]DOPO Tech is a good partner for brands seeking specialized PCAP expertise for their Custom Capacitive Touch Screen projects.[6]

When planning a Custom Capacitive Touch Screen, several technical parameters need to be defined clearly at the beginning of the project. Properly specifying these values helps avoid multiple rounds of redesign and speeds up the path to mass production.[7][2]Important parameters include:- Size and aspect ratio: Diagonal size, active area, and aspect ratio must match the LCD or OLED to be bonded with the Custom Capacitive Touch Screen.[7]- Cover glass: Thickness, edge shape (flat, chamfered, 2.5D), printing color, and logo position all influence appearance and durability.[7]- Touch points: Number of simultaneous touch points required for the Custom Capacitive Touch Screen, typically from single touch up to ten points or more.[2]- Interface: Communication interface between the touch controller and host system, such as USB, I2C, or SPI.[2]- Controller IC: Choice of controller affects noise immunity, OS compatibility, and glove or water performance.[2]By aligning these parameters with the final product requirements, the Custom Capacitive Touch Screen supplier can design a stable sensor and firmware from the start.[7]

Custom Capacitive Touch Screen devices for industrial or outdoor applications often face extreme temperatures, dust, vibration, and electromagnetic interference. Proper design and testing are therefore essential to ensure long‑term reliability.[2]Typical reliability measures include:- Temperature cycling and high‑low temperature tests to verify the stability of the Custom Capacitive Touch Screen stack and bonding materials.[2]- Vibration and drop tests to evaluate mechanical robustness of the glass and mounting structure.[2]- ESD and EMC tests to confirm that the Custom Capacitive Touch Screen controller and sensor can operate in noisy industrial environments.[2]- Life cycle tests for touch endurance to simulate years of heavy use in public or factory settings.[2]Customers should discuss these reliability requirements early in the Custom Capacitive Touch Screen project so that proper materials and processes are chosen.[2]

Selecting the right Custom Capacitive Touch Screen supplier is not only about price; long‑term cooperation and engineering capability are equally important. Buyers should evaluate the supplier's technical team, production scale, and communication efficiency.[1]Practical selection tips:- Review similar reference projects in the same industry to confirm experience with comparable Custom Capacitive Touch Screen specifications.[1]- Evaluate sample quality, including appearance, touch sensitivity, and compatibility with the intended LCD and system.[2]- Check whether the supplier can provide complete documentation such as drawings, test reports, and firmware versions for the Custom Capacitive Touch Screen.[2]- Consider lead time for both samples and mass production, especially when using large or unusual sizes.[1]A structured approach to supplier evaluation helps ensure a stable partnership for future Custom Capacitive Touch Screen projects as product volumes grow.[1]

Most Chinese manufacturers follow a similar OEM and ODM workflow when handling Custom Capacitive Touch Screen projects. Understanding this process allows buyers to prepare the right information and avoid delays.[7]Main steps:1. Requirement definitionThe customer provides size, drawings, environmental conditions, and interface requirements, as well as any special needs such as glove touch or water tolerance for the Custom Capacitive Touch Screen.[7]2. Proposal and quotationThe manufacturer proposes a sensor design, glass stack, and controller IC, plus tooling costs, unit pricing, and estimated lead times.[7]3. Prototype and testingPrototypes of the Custom Capacitive Touch Screen are produced and shipped for functional, EMC, and mechanical testing in the customer's device.[2]4. Design optimizationBased on test feedback, parameters and firmware are fine‑tuned, and drawings are updated before final approval.[7]5. Pilot run and mass productionA small pilot batch verifies process stability, after which full mass production starts with standard quality control for each Custom Capacitive Touch Screen lot.[2]Clear communication and timely feedback during this workflow are critical for keeping Custom Capacitive Touch Screen projects on schedule and within budget.[7]

| Supplier | Main Focus | Typical Size Range | Key Applications |

|---|---|---|---|

| New Vision Display (Shenzhen) | PRECI‑Touch Custom Capacitive Touch Screen + LCD | Small–medium | Automotive, medical, industrial HMIs. |

| Touch Think | Industrial monitors & panel PCs with PCAP front | 7–21.5 inch+ | Automation, kiosks, terminals. |

| BUNSUN Display | Industrial‑grade PCAP, G+G Custom Capacitive Touch Screen | 3.5–55 inch | Industrial, medical, finance, transport. |

| Touch‑China | Custom Capacitive Touch Screen and resistive panels | Various | Automotive, education, finance, retail. |

| CloudTop (Yunshang Electronic) | PCAP modules and Custom Capacitive Touch Screen | 3.5–75 inch | Industrial, medical, smart home. |

China offers a mature ecosystem of manufacturers capable of designing and producing Custom Capacitive Touch Screen solutions for almost any industry, from industrial automation to medical and smart retail applications. By evaluating leading suppliers such as New Vision Display, Touch Think, BUNSUN, Touch‑China, and others, overseas buyers can secure reliable, high‑performance Custom Capacitive Touch Screen modules and integrated devices.[2][1]For companies in sectors such as abrasives and refractory materials, adopting Custom Capacitive Touch Screen HMIs on production and inspection equipment can significantly improve productivity, traceability, and operator safety. With clear technical specifications, careful sample validation, and close cooperation with Chinese manufacturers, Custom Capacitive Touch Screen projects can move efficiently from concept to mass production.[7][2]

A Custom Capacitive Touch Screen is a projected capacitive touch panel designed according to specific customer requirements for size, shape, electronics, and environment rather than using a standard model. The supplier customizes the sensor pattern, cover glass, controller IC, and firmware so the Custom Capacitive Touch Screen integrates seamlessly with the final device.[7]

Buyers should prepare key parameters such as diagonal size, active area, mechanical drawings, cover glass thickness, printing color, and the desired interface for the Custom Capacitive Touch Screen. It is also important to describe temperature range, humidity, EMC conditions, glove or water operation needs, and any necessary certifications.[7][2]

Development time for a Custom Capacitive Touch Screen can range from a few weeks to several months depending on complexity and novelty of the design. Customization based on an existing standard structure is usually faster than a completely new sensor, glass, and controller combination.[7][2]

A Custom Capacitive Touch Screen offers better mechanical fit, branding, and user experience because its appearance and performance are optimized for a specific device. It can also provide improved durability and functionality in harsh environments by using thicker glass, special coatings, or tuned controller firmware.[7][2]

Many industrial‑grade Custom Capacitive Touch Screen designs support glove operation and limited water exposure through sensor layout and firmware optimization. Buyers should clearly specify glove type, thickness, and expected water conditions so the supplier can validate these features during development and testing.[2]

[1](https://ensun.io/search/custom-touch-screen/china)[2](https://bunsundisplay.com/pcap-touch-panel/)[3](https://www.future-displays.com/pcap-touch-screen/)[4](https://touchwo.com)[5](https://www.sztouchdisplay.com)[6](https://www.dopotouch.com)[7](https://www.touchlcddisplay.com/capacitive-touch-screen/)

Top 10 Multi Touch Capacitive Touchscreen Manufacturers in China

Top 10 Custom Capacitive Touch Screen Manufacturers in China

Top Capacitive Touch Screen Manufacturers and Suppliers in Turkey

Top Capacitive Touch Screen Manufacturers and Suppliers in Vietnam

Top Capacitive Touch Screen Manufacturers and Suppliers in South Korea

Top Capacitive Touch Screen Manufacturers and Suppliers in Japan

Top Capacitive Touch Screen Manufacturers and Suppliers in Italy