| Availability: | |

|---|---|

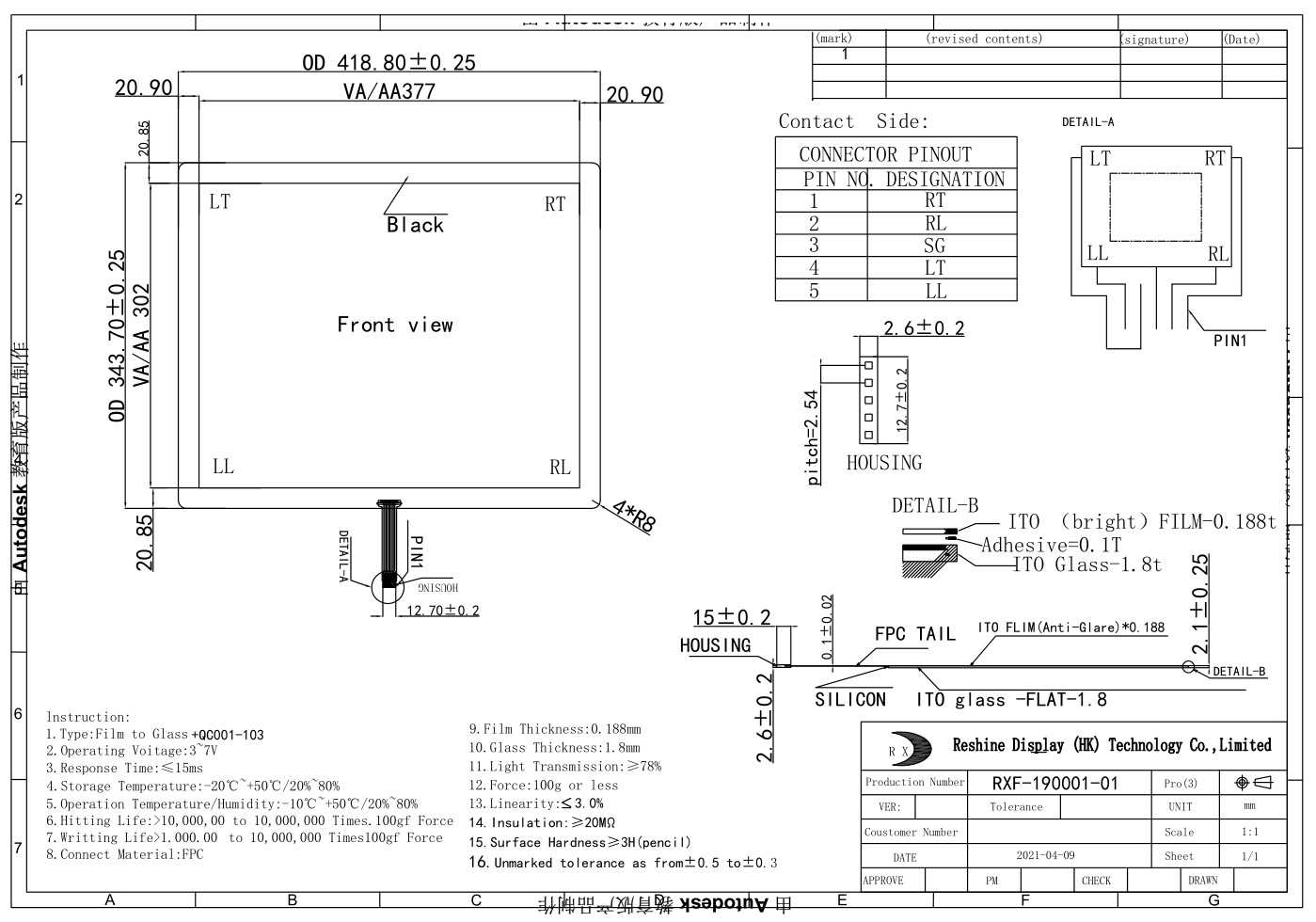

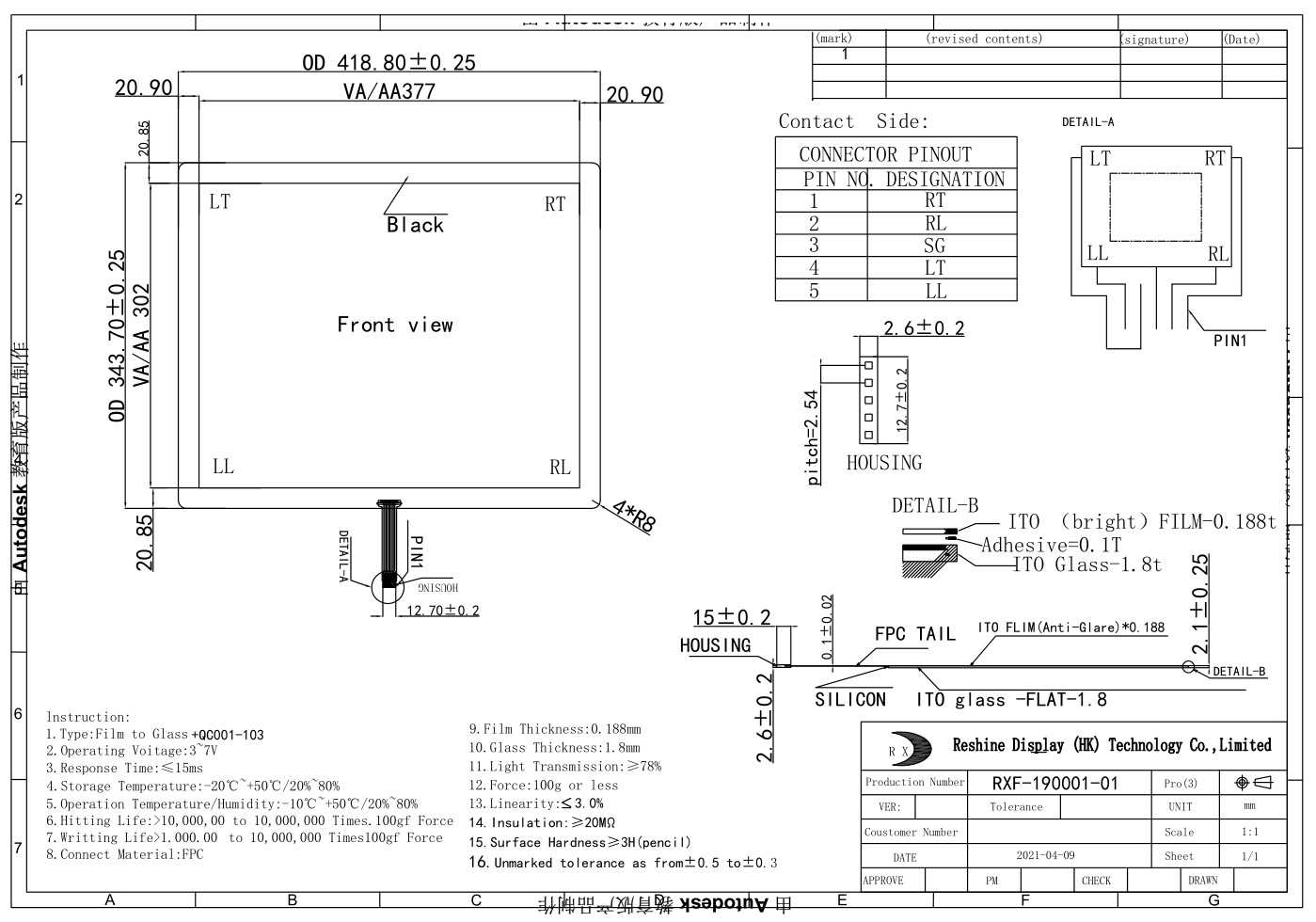

RXF-190001-01

Reshine Display

Product Description for 5 wire resistive touchscreens:

A 5-wire resistive touch screen is another type of touch screen technology commonly used in electronic devices. It is an improvement over the 4-wire resistive touch screen and offers certain advantages in terms of durability, accuracy, and ease of use.

Compared to the 4-wire resistive touch screen, the 5-wire resistive touch screen offers several advantages, including improved durability, increased accuracy, and better resistance to external factors such as dust and contaminants. It also requires less pressure to register a touch and has a longer lifespan. These factors make it suitable for a wide range of applications where accurate touch input is required, such as industrial equipment, kiosks, and medical devices.

Here's how a 5-wire resistive touch screen works:

Layers: Similar to the 4-wire resistive touch screen, a 5-wire resistive touch screen consists of two transparent resistive layers with a small air gap between them. The layers are typically made of a flexible material like polyester.

X-axis and Y-axis Layers: The bottom layer, also called the "glass" or "rigid" layer, is divided into two separate layers along the X-axis. These layers are connected to a constant voltage source. The top layer, known as the "touch" or "flexible" layer, has a single conductive layer that spans the entire surface and acts as a sensing electrode.

Voltage Application: Voltage is applied across the X-axis layers, generating a uniform voltage gradient along the X-axis. The voltage application is continuous.

Sensing Electrode: The sensing electrode in the top layer detects changes in voltage caused by touch input. It is connected to a sensing circuit.

Touch Detection: When a touch occurs on the top layer, the top layer presses against the bottom layers. This results in a localized change in resistance at the touch point, affecting the voltage distribution along the X-axis.

Sensing Circuit: The sensing circuit measures the voltage drop caused by the touch at the point of contact. It detects the change in resistance and calculates the X-axis position of the touch based on the voltage distribution and known positions of the X-axis layers.

Y-axis Measurement: The Y-axis position is determined separately by applying a constant voltage across the entire Y-axis layer and measuring the voltage at the touch point along the Y-axis.

Touch Recognition: The touch screen controller receives the X and Y coordinates obtained from the sensing circuit and calculates the precise location of the touch. This information is used to perform the desired action or input on the device.

7 key features of a 5-wire resistive touch screen with an LCD display:

Touch Sensitivity: 5-wire resistive touch screen displays are known for their high touch sensitivity, allowing for accurate and precise touch inputs.

Durability: The multiple layers and construction of 5-wire resistive touch screen displays make them durable and resistant to scratches and impact, making them suitable for rugged environments.

Resolution: These touch screen displays can support high-resolution displays, making them suitable for applications that require detailed graphics and visuals.

Touch Input: 5-wire resistive touch screen displays can detect touch input from a finger, stylus, or other objects, providing versatile and user-friendly interaction.

Single-Touch: 5-wire resistive touch screen displays typically support single-touch input, meaning they can detect only one touch point at a time.

Cost-Effectiveness: Compared to other touch screen technologies like capacitive touch screens, 5-wire resistive touch screens are generally more cost-effective, making them a popular choice for various applications.

Suitable Applications: 5-wire resistive touch screen displays are commonly used in industrial control panels, medical devices, POS systems, retail kiosks, and other applications where accurate touch input is required.

Resistive or capacitive touch screen which is best?

We manufacture resistive touch screen vs touchscreen with rich experiences, it's depends on client's application demands and application scenarios.

Hot tags:5-wire resistive touchscreen tft lcd display, 5-wire resistive touch screens, resistive touch lcd panel, resistive touch sensor, lcd resistive touchscreen, multi touch resistive screen, 5 wire resistive touch screen display, resistive touchscreen overlay, tft resistive touchscreen, 5-wire touchscreen resistive, china, customized, suppliers, factory, manufacturers

Product Description for 5 wire resistive touchscreens:

A 5-wire resistive touch screen is another type of touch screen technology commonly used in electronic devices. It is an improvement over the 4-wire resistive touch screen and offers certain advantages in terms of durability, accuracy, and ease of use.

Compared to the 4-wire resistive touch screen, the 5-wire resistive touch screen offers several advantages, including improved durability, increased accuracy, and better resistance to external factors such as dust and contaminants. It also requires less pressure to register a touch and has a longer lifespan. These factors make it suitable for a wide range of applications where accurate touch input is required, such as industrial equipment, kiosks, and medical devices.

Here's how a 5-wire resistive touch screen works:

Layers: Similar to the 4-wire resistive touch screen, a 5-wire resistive touch screen consists of two transparent resistive layers with a small air gap between them. The layers are typically made of a flexible material like polyester.

X-axis and Y-axis Layers: The bottom layer, also called the "glass" or "rigid" layer, is divided into two separate layers along the X-axis. These layers are connected to a constant voltage source. The top layer, known as the "touch" or "flexible" layer, has a single conductive layer that spans the entire surface and acts as a sensing electrode.

Voltage Application: Voltage is applied across the X-axis layers, generating a uniform voltage gradient along the X-axis. The voltage application is continuous.

Sensing Electrode: The sensing electrode in the top layer detects changes in voltage caused by touch input. It is connected to a sensing circuit.

Touch Detection: When a touch occurs on the top layer, the top layer presses against the bottom layers. This results in a localized change in resistance at the touch point, affecting the voltage distribution along the X-axis.

Sensing Circuit: The sensing circuit measures the voltage drop caused by the touch at the point of contact. It detects the change in resistance and calculates the X-axis position of the touch based on the voltage distribution and known positions of the X-axis layers.

Y-axis Measurement: The Y-axis position is determined separately by applying a constant voltage across the entire Y-axis layer and measuring the voltage at the touch point along the Y-axis.

Touch Recognition: The touch screen controller receives the X and Y coordinates obtained from the sensing circuit and calculates the precise location of the touch. This information is used to perform the desired action or input on the device.

7 key features of a 5-wire resistive touch screen with an LCD display:

Touch Sensitivity: 5-wire resistive touch screen displays are known for their high touch sensitivity, allowing for accurate and precise touch inputs.

Durability: The multiple layers and construction of 5-wire resistive touch screen displays make them durable and resistant to scratches and impact, making them suitable for rugged environments.

Resolution: These touch screen displays can support high-resolution displays, making them suitable for applications that require detailed graphics and visuals.

Touch Input: 5-wire resistive touch screen displays can detect touch input from a finger, stylus, or other objects, providing versatile and user-friendly interaction.

Single-Touch: 5-wire resistive touch screen displays typically support single-touch input, meaning they can detect only one touch point at a time.

Cost-Effectiveness: Compared to other touch screen technologies like capacitive touch screens, 5-wire resistive touch screens are generally more cost-effective, making them a popular choice for various applications.

Suitable Applications: 5-wire resistive touch screen displays are commonly used in industrial control panels, medical devices, POS systems, retail kiosks, and other applications where accurate touch input is required.

Resistive or capacitive touch screen which is best?

We manufacture resistive touch screen vs touchscreen with rich experiences, it's depends on client's application demands and application scenarios.

Hot tags:5-wire resistive touchscreen tft lcd display, 5-wire resistive touch screens, resistive touch lcd panel, resistive touch sensor, lcd resistive touchscreen, multi touch resistive screen, 5 wire resistive touch screen display, resistive touchscreen overlay, tft resistive touchscreen, 5-wire touchscreen resistive, china, customized, suppliers, factory, manufacturers

Top 7 Inch Hdmi Touch Screen Manufacturers And Suppliers in Vietnam

Top Capacitive Touch Display Manufacturers And Suppliers in Russia

Top Capacitive Touch Display Manufacturers And Suppliers in France

Top Capacitive Touch Display Manufacturers And Suppliers in Saudi Arabia

Top 7 Inch Hdmi Touch Screen Manufacturers And Suppliers in Turkey

Top 7 Inch Hdmi Touch Screen Manufacturers And Suppliers in South Korea

Top 7 Inch Hdmi Touch Screen Manufacturers And Suppliers in Japan

Top 7 Inch Hdmi Touch Screen Manufacturers and Suppliers in Italy

Top 7 Inch Hdmi Touch Screen Manufacturers And Suppliers in Spain

Top 7 Inch Hdmi Touch Screen Manufacturers And Suppliers in Russia