Views: 222 Author: Ella Publish Time: 2026-01-28 Origin: Site

Content Menu

● Understanding 4 Wire Resistive Touch Screen Technology

● Why Japan Matters for 4 Wire Resistive Touch Screens

● Top 4 Wire Resistive Touch Screen Manufacturers and Suppliers in Japan

>> DMC Co., Ltd. – Industrial Touch Panel Pioneer

>> Japanese HMI Brands Using 4 Wire Resistive Panels

>> TFT Display Makers Cooperating with 4 Wire Resistive Suppliers

>> Global OEM Factories Supporting Japanese Projects – Reshine Display

● How to Choose 4 Wire Resistive Touch Screen Manufacturers and Suppliers in Japan

>> Supply, Documentation, and Support

>> Cost and Customization Balance

● Example Applications Using 4 Wire Resistive Touch Screens

● Design and Integration Tips for 4 Wire Resistive Touch Screens

● Future Outlook for 4 Wire Resistive Technology in Japan

● FAQ

>> 1. What is a 4 wire resistive touch screen?

>> 2. Why choose Japanese 4 wire resistive touch suppliers?

>> 3. How does Reshine Display support Japanese projects?

>> 4. In which applications are 4 wire resistive touch screens most suitable?

>> 5. What should I check when selecting a 4 wire resistive supplier?

Resistive technology remains a reliable choice for industrial, medical, and commercial human–machine interfaces, and Japan hosts several influential 4 wire resistive touch screen manufacturers and suppliers that set high standards for quality and engineering support. For overseas buyers, working with these Japanese brands together with an OEM factory like Reshine Display is an effective way to secure stable, long‑term 4 wire resistive touch solutions and integrated TFT LCD assemblies.

4 wire resistive touch screens use two transparent conductive layers, usually ITO‑coated PET and glass, that are separated by tiny spacer dots and detect touch through changes in electrical resistance when the layers make contact under pressure. This structure allows 4 wire resistive touch panels to respond to finger, stylus, or gloved input, making them popular in harsh or contaminated environments where capacitive solutions may not work reliably.

Typical 4 wire resistive touch screen modules operate with a 5 V driving voltage, offer high insulation resistance, and achieve response times below 15 ms while maintaining light transmittance levels around or above 80 percent for acceptable display clarity. With proper sealing and cover lens design, 4 wire resistive assemblies can reach IP65‑level protection and survive millions of actuations in industrial control, medical, and commercial applications.

For designers, 4 Wire Resistive Touch Screen Manufacturers and Suppliers that support detailed mechanical drawings, controller IC options, and firmware tuning can greatly reduce development risk and speed up time‑to‑market. Because 4 wire resistive technology is mature and well understood, it also enables long product lifecycles, which is especially critical for industrial and medical device platforms that must stay in production for many years.

Japan has a long history in displays, semiconductors, and human–machine interfaces, so many core 4 Wire Resistive Touch Screen Manufacturers and Suppliers grew out of strong local ecosystems around industrial automation and electronics. These companies emphasize durability, traceability, and stable supply, which appeals to global buyers looking for dependable partners for factory equipment, kiosks, and professional terminals.

Japanese touch specialists frequently integrate 4 wire resistive sensors with TFT LCD modules and complete HMI assemblies, enabling customers to source full stacks from sensor to display instead of managing many separate vendors. At the same time, Japanese brands increasingly cooperate with overseas OEM factories like Reshine Display to optimize cost and customization while keeping strict quality benchmarks.

DMC is one of the best known Japanese companies dedicated to industrial touchscreens, providing both 4 wire and 5 wire resistive panels as well as controller solutions for demanding applications. Its product line is widely adopted in factory automation panels, logistics terminals, industrial PCs, and kiosk systems where stable performance and long‑term availability are essential.

DMC's 4 wire resistive touch products are engineered for high reliability, with controllers designed specifically for industrial use and long‑term adoption in control equipment. The company offers various sensor sizes, glass thicknesses, and connector types to help 4 Wire Resistive Touch Screen Manufacturers and Suppliers integrate panels into different HMI housing designs.

Because DMC operates under rigorous quality systems, it is often selected by machine builders that need consistent performance and strong documentation for global certifications. Its engineering resources and technical notes on resistive touchscreen principles help customers understand design trade‑offs for bezels, bonding, and controller calibration when using 4 wire resistive technology.

In addition to specialized sensor manufacturers, many Japanese HMI brands integrate 4 wire resistive touch panels into operator terminals and control panels for industrial automation and building management. These companies focus on complete devices that combine displays, touch sensors, CPUs, and communications interfaces into ready‑to‑install products for factories, infrastructure, and public facilities.

Such HMI brands typically choose 4 wire resistive technology for models that must support glove operation, high electromagnetic noise environments, or outdoor installations where water droplets and dust are common. For global buyers, these brands act as indirect 4 Wire Resistive Touch Screen Manufacturers and Suppliers because they define touch specifications and cooperate closely with sensor factories on design and quality control.

When sourcing from these Japanese HMI producers, equipment manufacturers can benefit from pre‑validated designs and extensive field experience, but they may have less flexibility in sensor customization compared with direct OEM cooperation. Therefore, some international companies combine finished Japanese HMI terminals for high‑end projects with custom 4 wire resistive modules from OEM partners like Reshine Display for cost‑sensitive or highly customized models.

Japan also hosts major TFT display manufacturers that regularly work with resistive touch partners to deliver integrated display plus touch modules. Companies such as Japan Display Inc., Sharp, Panasonic, Kyocera, and Ortustech provide TFT LCD cells and modules that often become the optical base for 4 wire resistive sensor bonding in industrial and automotive projects.

These TFT makers specialize in high brightness, wide temperature operation, and long product life, which are all important when combining with 4 wire resistive touch screen layers that may slightly reduce transmittance. Close collaboration between TFT suppliers and 4 Wire Resistive Touch Screen Manufacturers and Suppliers helps ensure proper optical matching, mechanical tolerances, and environmental reliability across the full HMI stack.

For global buyers, many Japanese TFT display manufacturers sell through networks of distributors, module assemblers, and OEM partners that can laminate 4 wire resistive sensors or provide completed touch display units. Working through these channels makes it easier to source matched components and simplifies qualification tests for vibration, temperature cycling, and EMC performance.

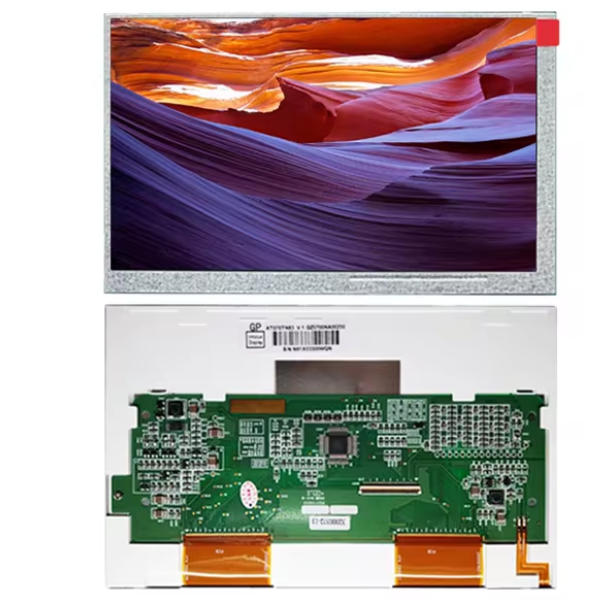

Reshine Display acts as a professional OEM factory for touch panels and TFT LCD modules, producing both standardized and customized 4 wire resistive touch screens for worldwide customers. The company's portfolio includes discrete 4 wire resistive sensors as well as fully integrated touch display modules covering a wide range of sizes for handheld devices, control panels, and embedded systems.

Reshine Display's 4 wire resistive touch screens are designed with high transparency, fast response times, and robust surface hardness, and many models can be designed to meet IP65 sealing requirements and pass strict reliability tests. Each 4 wire resistive panel typically undergoes reliability checks such as pencil hardness tests, actuation endurance, and environmental evaluations to support stable performance in industrial, medical, and commercial environments.

As an OEM partner, Reshine Display offers custom cover glass shapes, logo printing, tail and FPC designs, and controller IC selection, which helps 4 Wire Resistive Touch Screen Manufacturers and Suppliers in Japan and elsewhere expand their product lines. By combining Japanese design specifications with Reshine's cost‑effective manufacturing, overseas buyers can create display and touch solutions that address strict local standards while maintaining competitive pricing.

When evaluating 4 Wire Resistive Touch Screen Manufacturers and Suppliers, engineers should review optical performance, electrical parameters, mechanical robustness, and environmental capabilities. Important metrics include light transmittance, linearity, response time, operating voltage, insulation resistance, and surface hardness, all of which directly affect user experience and lifetime.

It is also vital to consider compatibility with the selected controller IC, interface type, and ESD protection strategy to guarantee stable operation in noisy industrial environments. Japanese suppliers and OEM partners that provide reference designs, evaluation boards, and tuning guidance can significantly simplify these integration tasks.

Beyond pure hardware specifications, 4 Wire Resistive Touch Screen Manufacturers and Suppliers differ in documentation quality, traceability, and lifecycle policies. Leading companies provide detailed 2D drawings, 3D models, interface guides, and integration notes that shorten the design cycle and minimize mechanical or electrical mismatches.

Long‑term availability and clear last‑time‑buy policies are especially important for industrial and medical equipment makers that need guaranteed supply for many years. Working with Japanese suppliers and OEM factories that coordinate production planning and buffer stock can reduce the risk of line stoppages or costly redesigns.

Japanese 4 Wire Resistive Touch Screen Manufacturers and Suppliers are often chosen for high‑reliability projects, but cost optimization still matters in competitive global markets. A common strategy is to define critical performance requirements with Japanese design partners and use overseas OEM factories like Reshine Display to handle customized variants or high‑volume production at favorable cost levels.

This dual‑source or cooperative model allows brands and equipment manufacturers to benefit from Japanese engineering and reputation while leveraging global manufacturing efficiencies. It is particularly effective when scaling families of devices that share similar 4 wire resistive touch interfaces but need different mechanical dimensions or branding.

4 Wire Resistive Touch Screen Manufacturers and Suppliers in Japan and their OEM partners support a wide variety of end markets including factory automation, logistics, medical devices, smart home systems, and security equipment. In these sectors, designers often value the ability of 4 wire resistive panels to detect input from gloved operators, styluses, or tools even in the presence of liquids or dust.

Reshine Display's 4 wire resistive touch screens, for example, can be used in industrial control panels, commercial and supermarket equipment, medical instruments, and automation machinery due to their durability and ease of integration. Japanese integrators combine these sensors with TFT displays from leading local manufacturers to create complete HMI solutions that can meet strict safety and performance standards.

For global OEMs, collaborating with Japanese 4 Wire Resistive Touch Screen Manufacturers and Suppliers and an OEM factory like Reshine Display enables consistent branding across product lines while meeting regional requirements for documentation, testing, and regulatory compliance. This approach also simplifies after‑sales service and spare parts management because the same core touch technology can be shared across multiple models and markets.

To extract the best performance from panels supplied by 4 Wire Resistive Touch Screen Manufacturers and Suppliers, engineers must pay attention to mechanical design around the touch assembly. The front bezel should avoid exerting continuous pressure on the active area while still protecting the edges from dust and moisture, and gasket materials should be chosen to balance sealing and mechanical stress.

On the electronics side, careful routing of touch panel signal lines and proper grounding help reduce noise and improve coordinate stability. Designers should allocate time for calibration and controller tuning, especially if the 4 wire resistive panel is bonded to a high‑brightness TFT LCD that may introduce additional heat and stresses during operation.

For user experience, it is helpful to consider expected input methods at the early design stage. If operators will frequently use thick gloves or styluses, designers may specify a slightly thicker or more robust top film from their chosen 4 Wire Resistive Touch Screen Manufacturers and Suppliers, or adjust firmware settings to ensure smooth and accurate recognition of press events.

While projected capacitive technology dominates many consumer applications, 4 wire resistive touch screens still retain strong demand in industrial and specialized markets. Japanese suppliers continue to refine materials and structures to improve optical clarity, surface hardness, and longevity, ensuring that resistive solutions remain competitive for demanding environments.

In addition, more projects now combine 4 wire resistive sensors with advanced TFT LCDs that offer wide viewing angles, high brightness, and extended temperature ranges. This combination delivers rugged user interfaces suitable for outdoor terminals, vehicle‑mounted systems, and industrial equipment lines where reliability is more important than multi‑touch gestures.

For overseas buyers, the ecosystem of Japanese 4 Wire Resistive Touch Screen Manufacturers and Suppliers, TFT makers, and global OEM factories like Reshine Display will likely remain a key source of stable, well‑documented solutions over the coming years. As industrial digitalization accelerates, this ecosystem will continue to support upgrades from mechanical keypads and indicator lights to intuitive touch‑based HMIs.

4 wire resistive touch screens remain a practical and widely adopted choice for harsh and industrial environments, and Japan's ecosystem of touch panel specialists, HMI brands, and TFT display manufacturers plays a central role in the global supply chain. By working with reputable 4 Wire Resistive Touch Screen Manufacturers and Suppliers in Japan and partnering with an experienced OEM factory like Reshine Display, buyers can achieve a balanced combination of quality, customization, and cost for long‑term projects.

Reshine Display provides standardized and customized 4 wire resistive panels and integrated TFT LCD modules, making it a flexible OEM partner for Japanese and international customers seeking mature, dependable touch technology. Whether for industrial control, medical equipment, or commercial systems, carefully selecting suppliers and structuring cooperation between Japanese brands and global manufacturers is the foundation of successful 4 wire resistive HMI platforms.

Contact us to get more informations!

A 4 wire resistive touch screen is a sensor composed of two transparent conductive layers separated by spacer dots; when pressed, the layers make contact and the controller calculates the touch position from the resulting voltage changes. This technology works with fingers, styluses, or gloves and is widely used by 4 Wire Resistive Touch Screen Manufacturers and Suppliers for industrial and commercial devices.

Japanese 4 Wire Resistive Touch Screen Manufacturers and Suppliers are known for strong engineering, complete documentation, and strict quality control, which are crucial in industrial and medical projects. They also tend to provide long product lifecycles and stable supply, making them reliable partners for equipment makers that must support platforms in the field for many years.

Reshine Display manufactures a wide range of 4 wire resistive touch screens and TFT LCD modules and can customize shape, tail, cover glass, and controller selection for specific projects. As an OEM partner, it can cooperate with Japanese 4 Wire Resistive Touch Screen Manufacturers and Suppliers and HMI brands to deliver cost‑effective yet reliable touch display assemblies for global buyers.

4 wire resistive touch screens perform well in industrial control panels, medical devices, commercial terminals, logistics equipment, and environments with dust, liquids, or operators wearing gloves. Many Japanese and global 4 Wire Resistive Touch Screen Manufacturers and Suppliers target these markets because resistive technology offers predictable behavior, simple interfaces, and long‑term availability.

Buyers should evaluate optical transmittance, surface hardness, environmental ratings, controller compatibility, and documentation quality when comparing 4 Wire Resistive Touch Screen Manufacturers and Suppliers. It is also wise to confirm customization capabilities, lifecycle policies, and cooperation models with OEM factories like Reshine Display for future product extensions and cost optimization.

1. https://www.reshine-display.com/top-5-wire-resistive-touch-screen-manufacturers-and-suppliers-in-japan.html

2. https://www.reshine-display.com/4-0-resistive-touch-screen.html

3. https://www.reshine-display.com/top-tft-display-manufacturers-and-suppliers-in-japan.html

4. https://www.dush.co.jp/english/product/

5. https://www.dush.co.jp/english/method-type/resistive-touchscreen/principle/

6. https://www.reshine-display.com/products/4-wire-resistive-screen.html

Top 3.5 Inch LCD Display Manufacturers And Suppliers in Portugal

Top 3.5 Inch LCD Display Manufacturers And Suppliers in Spain

Top 3.5 Inch LCD Display Manufacturers And Suppliers in Russia

Top 3.5 Inch LCD Display Manufacturers And Suppliers in France

Top 3.5 Inch LCD Display Manufacturers And Suppliers in Saudi Arabia

Top 4 Wire Resistive Touch Screen Manufacturers And Suppliers in Turkey

Top 4 Wire Resistive Touch Screen Manufacturers and Suppliers in Vietnam

Top 4 Wire Resistive Touch Screen Manufacturers And Suppliers in South Korea