Views: 222 Author: Ella Publish Time: 2026-01-24 Origin: Site

Content Menu

● Why South Korea Matters for 5‑Wire Resistive Touch

>> Key Market Drivers in South Korea

● How 5‑Wire Resistive Technology Works

>> Main Advantages for Industrial Users

● Top 5 South Korean Resistive Touch Specialists

>> 1. Touch & Display Co., Ltd.

>> 3. Inotouch Technology Co., Ltd.

>> 4. TLVision

>> 5. Hantouch and Other Industrial Providers

● Typical Application Fields in South Korea

>> Industrial Automation and Panel PCs

>> Kiosks, Ticketing, and Public Terminals

>> Medical Devices and Laboratory Equipment

● Technical Points When Choosing 5‑Wire Resistive Screens

● Reshine Display as a Global OEM Partner

>> Reshine 5‑Wire Resistive Portfolio Highlights

● Working with South Korean Partners and Reshine Display

>> Recommended Cooperation Workflow

● Comparing Local Korean Suppliers and OEM Partners

● Practical Tips for Global Buyers

● Adding Multimedia to Support Your Story

● FAQ

>> Q1: Why do many South Korean projects still use 5‑wire resistive touch instead of capacitive?

>> Q3: How do South Korean suppliers and Reshine Display usually cooperate on projects?

>> Q4: What should I check before choosing a 5‑wire resistive solution for my equipment?

South Korea has built a mature ecosystem of 5 wire resistive touch screen manufacturers and suppliers serving industrial automation, kiosks, medical devices, and transportation projects worldwide. For global OEMs, wholesalers, and device brands, combining South Korean engineering with reliable OEM factories like Reshine Display in China is an efficient way to secure stable, customizable 5‑wire resistive touch solutions.

An opening visual can show a modern South Korean factory floor where operators interact with industrial HMIs using rugged 5‑wire resistive touch screens, emphasizing robust enclosures and clear TFT displays.

South Korea's broader resistive touchscreen market is expanding on the back of Industry 4.0 upgrades, smart factories, and industrial automation, all of which require reliable human–machine interfaces. These trends ensure that 5 wire resistive touch screen manufacturers and suppliers remain strategically important even as capacitive technology grows in consumer devices.

A detailed visual here could focus on a close‑up of a resistive touch control panel in a Korean automotive or electronics plant, with gloved hands operating a panel PC under bright factory lighting.

- Government‑backed digital transformation and smart factory programs increase demand for rugged touch interfaces in manufacturing and logistics.

- Industrial buyers favor 5‑wire resistive solutions in harsh, noisy, or outdoor environments where gloves, stylus operation, and moisture resistance are essential.

- South Korea's concentration of display and electronics companies provides a strong base for specialized 5 wire resistive touch screen manufacturers and suppliers with export experience.

A supporting visual can display an infographic‑style cross‑section of 5‑wire resistive touch structure layered over a TFT LCD, with labels for top film, glass substrate, electrodes, and controller.

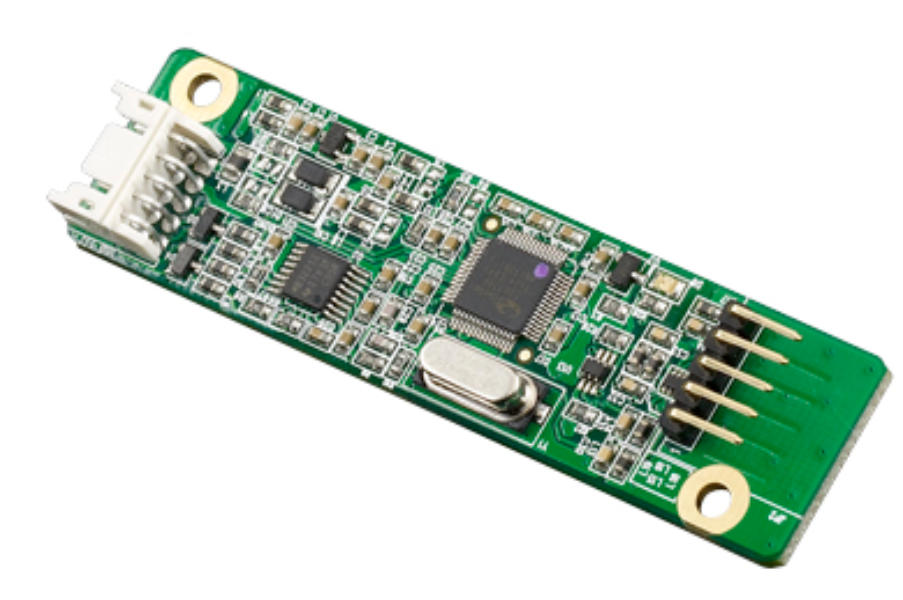

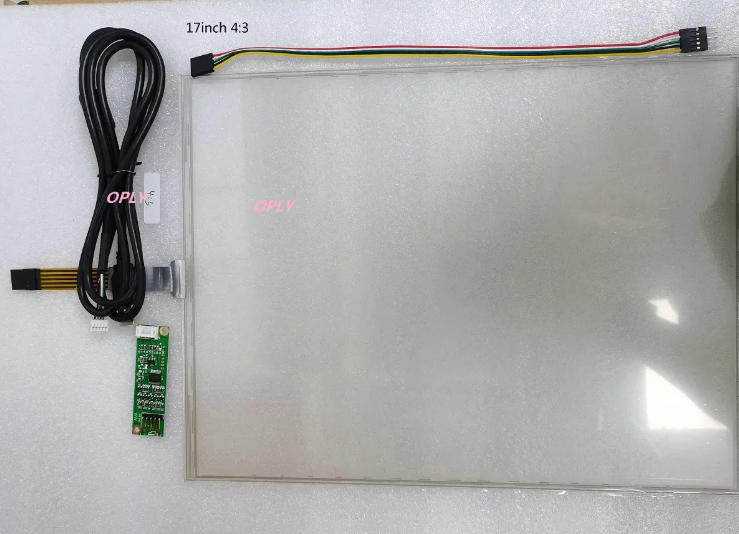

A 5‑wire resistive touch screen uses a conductive coating on a rigid glass substrate plus a flexible top film, with voltage applied across the bottom layer and the top layer acting mainly as a probe. When users press the surface, the layers make contact, and the controller calculates the X and Y coordinates based on voltage changes, enabling accurate single‑touch operation.

You can add a schematic‑style visual here that illustrates the step‑by‑step touch process: finger or stylus pressure, layer contact, analog signal generation, and the controller converting to digital coordinates.

- Durability: Because only the bottom glass layer is actively measured, 5‑wire resistive screens maintain calibration longer and tolerate repeated use.

- High compatibility with fingers, gloves, and stylus, which is vital in medical, food processing, and heavy‑industry environments.

- Stable performance under dust, oil, and electromagnetic noise, making 5‑wire resistive a reliable choice for many 5 wire resistive touch screen manufacturers and suppliers in South Korea.

A visual example can show a medical monitor with a 5‑wire resistive front panel used in a Korean hospital, with a nurse interacting using medical gloves.

South Korea's leading resistive touch screen providers offer standard and custom 4‑wire and 5‑wire panels, often integrated into monitors, panel PCs, or full HMI terminals. For buyers seeking 5 wire resistive touch screen manufacturers and suppliers, several names stand out for engineering strength, export experience, and industrial focus.

A visual concept here: a comparative layout showing several branded control panels and kiosks sourced from different Korean vendors, each using resistive touch.

Touch & Display Co., Ltd. is recognized as a Korean specialist providing display and touch modules for industrial, kiosk, and embedded applications. It supplies resistive touch screens that can be combined with TFT LCDs and tailored via coating options, bonding methods, and controller choices, positioning it among the prominent 5 wire resistive touch screen manufacturers and suppliers serving local and overseas OEMs.

An accompanying visual can highlight an industrial control cabinet with a Touch & Display‑style front panel, showing IP‑rated front bezels and resistive touch integration.

Alpha Display Co., Ltd. is known for producing industrial displays and touch modules, often delivered as open‑frame monitors or integrated assemblies for equipment makers. Its portfolio includes resistive touch solutions in multiple sizes, giving 5 wire resistive touch screen manufacturers and suppliers and system integrators standardized building blocks for machine interfaces and kiosks.

Here, you might show an ATM or ticketing terminal in a Korean railway station using a resistive touch display, with clear brightness and anti‑reflection treatment.

Inotouch Technology Co., Ltd. focuses on touch solutions for various industries and provides resistive panels that can be adapted for compact or larger control systems. As part of the 5 wire resistive touch screen manufacturers and suppliers ecosystem, it supports OEM customization in aspects such as outline dimensions, connector locations, and optical treatments.

A conceptual visual could depict a small laboratory analyzer with an Inotouch‑type resistive touch user interface, emphasizing clean design and precise stylus operation.

TLVision operates as a development and manufacturing partner offering multiple touch technologies, including resistive modules for custom industrial equipment and OEM devices. Its engineering capabilities in R&D, prototyping, and mass production make it valuable for 5 wire resistive touch screen manufacturers and suppliers that require co‑design of front panels, controller integration, and EMI‑robust solutions.

You can insert a visual of a rugged panel PC mounted on heavy machinery, showing a bright TFT display under sunlight with resistive touch front glass.

Hantouch is often cited for its range of standard resistive touch panels from small 5.7‑inch sizes up to larger formats used in automation and kiosk systems. These analog resistive modules are favored by many 5 wire resistive touch screen manufacturers and suppliers thanks to their consistent performance, straightforward controller options, and suitability for wide‑temperature operation.

A useful visual can show a multi‑screen industrial operator station where several Hantouch‑type panels display process data and alarms, all accessible by resistive touch.

South Korean manufacturers combine resistive front panels with rugged panel PCs and monitors for factory automation, robotics, and process control. In transportation, kiosks, and ticketing systems, 5 wire resistive touch screen manufacturers and suppliers support wide‑temperature, vandal‑resistant terminals that remain readable outdoors and functional with gloves or stylus input.

A visual here can show a metro ticketing or self‑service check‑in terminal in Seoul, highlighting steady operation despite high traffic and variable weather.

- Panel PC makers integrate resistive touch, fanless PCs, and wide‑temperature TFT LCDs into sealed metal housings for production lines and machine tools.

- For many 5 wire resistive touch screen manufacturers and suppliers, these industrial HMIs represent a core market because lifecycle expectations are long and components must stay available for many years.

- Ticketing machines, payment kiosks, and information terminals across South Korea frequently rely on resistive touch for reliable single‑touch operation.

- 5 wire resistive touch screen manufacturers and suppliers collaborate with enclosure makers, printer suppliers, and payment system vendors to deliver complete field‑ready terminals.

- Medical monitors, diagnostic analyzers, and laboratory instruments require touch interfaces that remain operable with gloves and withstand regular disinfection.

- South Korean 5 wire resistive touch screen manufacturers and suppliers therefore emphasize chemical resistance, easy‑to‑clean surfaces, and long product lifecycles for healthcare projects.

A practical visual can show a compact diagnostic device with a resistive touch front panel in a hospital lab setting, including gloved clinical staff.

To choose the right 5 wire resistive touch screen manufacturers and suppliers in South Korea or abroad, buyers should specify mechanical, optical, and electrical requirements in detail. Clear specifications simplify sampling, shorten project timelines, and ensure that the final solution matches regulatory and environmental needs.

- Size and aspect ratio: from around 5.7 inches to more than 21.5 inches, often matching standard TFT LCD sizes used in industrial and kiosk projects.

- Surface treatments: anti‑glare, anti‑reflection, and optional hard‑coating to resist scratches or chemicals, common among experienced 5 wire resistive touch screen manufacturers and suppliers.

- Electrical interface and controller: USB, RS‑232, or I⊃2;C controllers, often supplied or recommended by the manufacturer for easy integration.

A technical diagram visual can show a selection of resistive front panels over different TFT sizes, annotated with key metrics like brightness, viewing angle, and touch life cycles.

Reshine Display is a professional factory in China specializing in standardized and custom touch screens and TFT LCD modules, including 5‑wire resistive options for global OEMs. By supporting customized sizes, FPC layouts, cover lens printing, and bonding methods, Reshine Display helps brands, wholesalers, and equipment makers integrate reliable 5‑wire resistive touch into their finished products.

Reshine Display works closely with system integrators and distributors around the world, including South Korean partners, to supply competitive 5‑wire resistive assemblies for industrial, kiosk, and medical applications. This positions Reshine Display as a key member of the international network of 5 wire resistive touch screen manufacturers and suppliers.

A visual here can depict a Reshine Display‑style production line with cleanroom assembly of touch panels, TFT bonding, and final inspection for export orders.

- Multiple size options, from small diagonals to large formats like 12.1‑inch, 15‑inch, and 21.5‑inch touch‑plus‑TFT assemblies.

- Flexible customization for outline dimensions, viewing window size, logo or frame printing, and special surface treatments.

- Engineering support throughout the design‑in process, including samples, drawings, and controller recommendations tailored to OEM needs.

Here, an application‑focused visual can present a side‑by‑side arrangement of finished devices (panel PCs, medical displays, kiosks) that all use Reshine‑supplied 5‑wire resistive touch and TFT assemblies.

For many projects, the optimal strategy is to cooperate with local South Korean engineering firms or system integrators while sourcing 5‑wire resistive touch assemblies from high‑volume OEM factories like Reshine Display. This approach leverages local market knowledge and service with the production efficiency and customization expertise of established 5 wire resistive touch screen manufacturers and suppliers.

A visual in this section can show a project workflow diagram: requirements definition in South Korea, co‑design with Reshine Display, sampling, validation, and mass production.

- Define usage scenarios, target environment, certifications, and expected lifecycle together with your South Korean engineering partner.

- Engage an OEM such as Reshine Display early for touch and TFT stack design, mechanical drawings, and interface definition, ensuring alignment with 5 wire resistive touch screen manufacturers and suppliers capabilities.

- Validate sample units in real operating conditions, then move to mass production with documented quality and logistics agreements.

You can enrich this part with a visual of a cross‑functional project team reviewing CAD drawings and prototype devices in a lab environment.

South Korean suppliers and overseas OEM factories each bring distinct strengths when you choose among 5 wire resistive touch screen manufacturers and suppliers for your project.

Aspect | South Korean suppliers | OEM factory (Reshine Display) |

Main role | Local engineering, integration, and system design for industrial, medical, and kiosk projects. | High volume production of 5 wire resistive touch and TFT LCD assemblies with custom options. |

Strengths | Deep understanding of South Korean standards, on site support, quick prototyping and integration into local equipment. | Cost effective manufacturing, wide size range, rich customization, and export ready quality systems. |

Typical deliverables | Complete panel PCs, industrial monitors, or application specific terminals using resistive touch. | Stand alone 5 wire resistive panels or touch plus TFT modules for 5 wire resistive touch screen manufacturers and suppliers and brands. |

Best use case | Projects needing local installation, maintenance, and fast field support in South Korea. | Global rollouts requiring stable long term supply and fine tuned customization at the component level. |

A visual here can depict two routes: one showing a Korean system integrator delivering complete equipment, and another showing Reshine Display shipping component kits to multiple global factories.

When evaluating 5 wire resistive touch screen manufacturers and suppliers serving South Korea, buyers should look beyond unit price and assess long‑term technical and logistical fit. The right framework minimizes risk while enabling performance and customization.

- Verify quality systems and certifications for both South Korean partners and OEM factories.

- Confirm product lifecycle support, including guaranteed availability windows and second‑source planning among compatible 5 wire resistive touch screen manufacturers and suppliers.

- Evaluate engineering support: drawing turnaround time, firmware or controller assistance, and responsiveness during sampling and ramp‑up.

A visual can show a procurement team reviewing supplier scorecards and technical datasheets, emphasizing structured vendor selection.

To better showcase the ecosystem of 5 wire resistive touch screen manufacturers and suppliers in South Korea, it is helpful to embed several visuals and videos throughout the article.

- At the beginning, add a scene from an advanced South Korean smart factory where operators use rugged resistive touch HMIs on production lines.

- In the technology section, embed an animation or explainer video that breaks down the internal structure of a 5‑wire resistive panel and compares it with other touch technologies.

- When introducing typical applications, include short clips of kiosks in metro stations, hospital monitoring equipment, and industrial control panels in operation.

- In the cooperation workflow part, a short interview‑style video with an engineer from Reshine Display or a Korean integrator can explain how joint projects progress from concept to mass production.

- Near the end, a montage‑style video can summarize key benefits of using 5 wire resistive touch screen manufacturers and suppliers for long‑lifecycle industrial and medical products.

These multimedia elements not only make the article more engaging but also help potential buyers clearly visualize how 5‑wire resistive solutions perform in real applications.

South Korea's ecosystem of resistive touch specialists—such as Touch & Display, Alpha Display, Inotouch Technology, TLVision, and Hantouch—offers strong options for industrial, kiosk, and medical projects that still rely on 5‑wire resistive technology. By partnering with these local experts and combining them with OEM factories like Reshine Display, buyers can access a robust network of 5 wire resistive touch screen manufacturers and suppliers that deliver durable, glove‑friendly, and customizable solutions for demanding environments.

A final visual suggestion is a collage of multiple end‑use scenarios—factories, hospitals, kiosks, and transport hubs—all running equipment built on 5‑wire resistive touch and TFT LCD assemblies from this ecosystem.

Contact us to get more informations!

5‑wire resistive touch remains popular in South Korea because it tolerates gloves, stylus, moisture, and electrical noise better than many consumer‑grade capacitive solutions, which is essential in industrial and medical environments. For many 5 wire resistive touch screen manufacturers and suppliers, long‑term stability and predictable behavior are more important than multi‑touch or gesture support.

Common offerings range from compact panels around 5.7 inches up to larger formats above 20 inches, such as 12.1‑inch and 21.5‑inch modules that match industrial and kiosk TFT displays. Many manufacturers and suppliers also support custom outlines, viewing windows, and cover glass printing for branded equipment fronts.

South Korean suppliers often handle local engineering, enclosure design, and system integration, while Reshine Display provides the 5‑wire resistive touch and TFT assemblies as an OEM partner. Together, they allow 5 wire resistive touch screen manufacturers and suppliers and device brands to combine market‑specific features with efficient, scalable component manufacturing.

You should clarify operating temperature range, expected lifetime, chemical exposure, required brightness, interface type, and certification needs before engaging suppliers. Sharing these details early helps 5 wire resistive touch screen manufacturers and suppliers in South Korea and OEM partners like Reshine Display propose the most suitable stack‑up and controller configuration.

Modern 5‑wire resistive touch screens paired with quality TFT LCDs can deliver good optical clarity, LED‑backlit brightness, and responsive single‑touch input, especially in industrial and kiosk applications. When specified and integrated carefully by experienced 5 wire resistive touch screen manufacturers and suppliers, they provide a robust balance of usability, reliability, and cost for long‑lifecycle equipment.

1. Global resistive touchscreen market and industrial trends

2. South Korea resistive touch and smart factory background

3. Korean industrial display and touch module suppliers

4. Technical information on 5‑wire resistive touch structures

5. Reshine Display 5‑wire resistive touch and TFT LCD product information

Top 7 Inch TFT Display Manufacturers And Suppliers in France

Top 7 Inch TFT Display Manufacturers And Suppliers in Saudi Arabia

Top 5 Wire Resistive Touch Screen Manufacturers And Suppliers in Turkey

Top 5 Wire Resistive Touch Screen Manufacturers And Suppliers in Vietnam

Top 5 Wire Resistive Touch Screen Manufacturers And Suppliers in South Korea

Top 5 Wire Resistive Touch Screen Manufacturers And Suppliers in Japan

Top 5 Wire Resistive Touch Screen Manufacturers And Suppliers in Portugal

Top 5 Wire Resistive Touch Screen Manufacturers And Suppliers in Italy