Views: 222 Author: Wendy Publish Time: 2025-12-17 Origin: Site

Content Menu

● Switzerland's Strength in Capacitive Touch Screen Technology

● Overview of Capacitive Touch Screen Technologies

● Core Components of a Capacitive Touch Screen System

● Leading Swiss Capacitive Touch Screen and HMI Players

>> SCHURTER – Custom PCAP Touch HMI Solutions

>> Advanced Silicon SA – Capacitive Controller and Electronics Expertise

>> DMB Technics – Customized Display Modules and HMI Integration

>> FORTEC Switzerland – Display and Touch Integration Specialist

>> Simpex Electronic AG – Value‑Added Distribution and Project Support

● Typical Applications of Capacitive Touch Screen in Switzerland

● Capacitive Touch Screen in Abrasives and Refractory Production

● Design and Customization Options

● Environmental and Regulatory Considerations

● Cooperation Models with Swiss Capacitive Touch Screen Suppliers

● Key Selection Criteria for Global Buyers

● Future Trends in Swiss Capacitive Touch Screen Solutions

● FAQ – Capacitive Touch Screen in Switzerland

>> (1) What is a Capacitive Touch Screen and why is it preferred in industrial projects?

>> (2) Can Swiss suppliers customize Capacitive Touch Screen modules for specific machines?

>> (3) How do Capacitive Touch Screen solutions handle gloves, water, or dust?

>> (4) Which industries in Switzerland most commonly use Capacitive Touch Screen interfaces?

>> (5) What should overseas buyers check before selecting a Swiss Capacitive Touch Screen partner?

Switzerland has built a strong reputation for high‑reliability Capacitive Touch Screen solutions, especially for industrial, medical, transportation, and premium commercial applications where precision and long product lifecycles are critical. For global OEMs and system integrators, working with Swiss Capacitive Touch Screen manufacturers and suppliers means combining advanced engineering with robust supply chain support across Europe and worldwide.

Swiss engineering culture emphasizes precision, reliability, and long‑term availability, which fits the requirements of industrial Capacitive Touch Screen projects that must operate 24/7 in demanding environments. Many Swiss suppliers focus less on consumer devices and more on customized Capacitive Touch Screen modules, HMI panels, and complete display systems with tailored mechanics and electronics.

For international buyers, Switzerland serves as a gateway to European standards and certifications, making Swiss Capacitive Touch Screen solutions attractive for regulated sectors such as medical technology, transportation, and process automation. Swiss companies often combine local engineering with global production networks, allowing flexible volumes and competitive total cost of ownership for Capacitive Touch Screen projects.

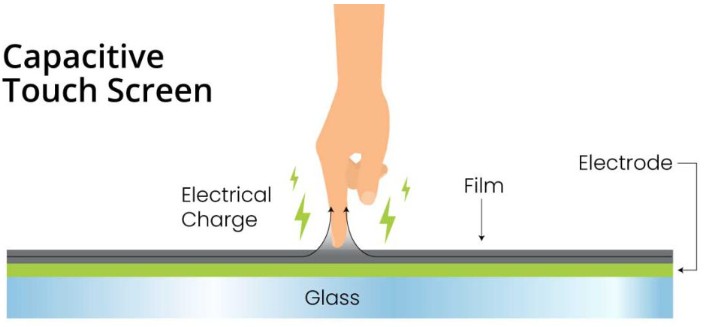

Modern suppliers typically offer Projected Capacitive (PCAP) technology, which uses an electrostatic field across transparent conductive layers to detect changes caused by fingers or conductive styluses. A PCAP Capacitive Touch Screen supports multi‑touch gestures, high light transmission, and robust front glass designs suitable for vandal‑resistant and outdoor applications.

Compared with resistive touch, a Capacitive Touch Screen provides better optical clarity, support for gesture control, and longer mechanical life because there is no need for physical pressure. For harsh environments, manufacturers can combine a Capacitive Touch Screen sensor with thick cover glass, optical bonding, anti‑glare or anti‑reflection coatings, and custom sealing to reach high protection levels such as IP65 or higher on the front side.

A typical industrial Capacitive Touch Screen solution consists of several key layers and components working together as a system. Understanding these elements helps buyers evaluate the technical level of different Swiss manufacturers and suppliers.

The front cover glass is the visible surface of the Capacitive Touch Screen and is often made from chemically strengthened glass, sometimes up to several millimeters thick for industrial or outdoor use. Beneath the glass sits the PCAP sensor, a transparent conductive pattern that creates a grid of electrodes to measure changes in capacitance when a user touches the surface.

A dedicated touch controller interprets raw signals from the sensor and converts them into precise coordinates and gestures that the host system can understand. Finally, the Capacitive Touch Screen is optically bonded or mechanically assembled to a TFT or LCD display module and integrated into a housing, panel PC, or complete HMI device. Each of these steps offers opportunities for customization and quality differentiation among Swiss manufacturers.

Switzerland's Capacitive Touch Screen ecosystem includes specialist component makers, HMI system providers, and distribution partners that configure tailored solutions around TFT and LCD modules. Below are representative players and their typical strengths in Capacitive Touch Screen projects.

SCHURTER is a globally recognized provider of complete HMI solutions that integrate PCAP Capacitive Touch Screen modules, displays, and electronics into robust front panels. The company focuses on customized Projected Capacitive Touch Screen designs with tailored glass, sensor patterns, and controller tuning for medical, industrial machinery, and transportation applications.

In many projects, SCHURTER delivers not just a bare Capacitive Touch Screen, but a complete front panel including mechanical frame, backlighting, and integrated electronics. The company's emphasis on standards, EMC performance, and long‑term availability makes its Capacitive Touch Screen solutions attractive for equipment that must stay in service for 10 years or more.

Advanced Silicon SA concentrates on hardware, firmware, and software for interactive and intelligent displays, supplying capacitive touch ICs and control boards. Its Projected Capacitive Touch Screen control boards are designed for displays of various sizes and support multi‑touch, high noise immunity, and accurate gesture recognition.

Although it does not primarily market finished HMI devices, Advanced Silicon technology is often embedded inside higher‑level Capacitive Touch Screen modules and systems produced by other manufacturers. For OEMs that want to optimize performance, noise immunity, or glove functionality, close cooperation with a controller specialist such as Advanced Silicon helps fine‑tune the Capacitive Touch Screen behavior.

DMB Technics is known as an expert in customized display systems and electronic display solutions for industrial use. The company develops tailored display modules and HMI systems that integrate Capacitive Touch Screen sensors, TFT displays, and dedicated controller electronics.

Rather than selling generic off‑the‑shelf panels, DMB Technics focuses on project‑specific configurations where the Capacitive Touch Screen size, resolution, brightness, and mechanical integration are optimized for each customer's device. This is ideal for OEMs that need unique front designs, custom cover glass shapes, or specific interfaces such as LVDS, HDMI, or industrial communication options.

FORTEC Switzerland acts as a specialist in display technologies, power supplies, and embedded systems, offering TFT LCD display modules, touchscreens, and controller boards. The company often combines TFT panels with PCAP Capacitive Touch Screen sensors and embedded computing platforms to deliver complete industrial display solutions.

Instead of simply distributing bare LCDs, FORTEC configures full platforms that include the Capacitive Touch Screen, mechanics, electronics, and sometimes an integrated CPU board or box PC. This integration capability reduces development effort for OEM customers and supports a clear path from prototype to series production with minimal redesign.

Simpex Electronic AG operates as a distributor focused on industrial and professional electronics, including many types of display modules. Its portfolio includes TFT LCD displays with and without touch, allowing customers to specify PCAP Capacitive Touch Screen options for instrument panels, control stations, and kiosks.

For many small and medium‑sized OEMs, Simpex serves as the bridge between global display and Capacitive Touch Screen manufacturers and local Swiss engineering teams. The company helps select suitable panels, coordinates customizations, and supports logistics, making it easier to implement Capacitive Touch Screen interfaces without building a deep in‑house display engineering capability.

Swiss Capacitive Touch Screen manufacturers and suppliers serve a wide mix of industries aligned with the country's strengths in precision machinery, life sciences, and transportation. Major application fields include industrial automation HMIs, medical devices, railway and public transport systems, building automation, and high‑end retail or kiosk installations.

In industrial automation, Capacitive Touch Screen panel PCs and operator terminals present process data, alarms, and recipes on bright, high‑resolution displays. Operators can pinch, zoom, and swipe through different views, while a flat glass surface simplifies cleaning and resists contamination. In medical devices, Capacitive Touch Screen interfaces must withstand disinfectants and support operation with thin gloves, making controller tuning and surface coatings especially important.

For factories producing abrasives, refractory materials, and related industrial products, upgrading machine controls to Capacitive Touch Screen HMIs can significantly improve usability and efficiency. Grinding machines, kilns, mixers, and inspection equipment can all benefit from a modern Capacitive Touch Screen interface that centralizes parameters, recipes, and alarms.

With a Capacitive Touch Screen, operators can adjust speed, pressure, temperature, and timing more intuitively than with mechanical switches or basic text displays. Real‑time data visualization on a Capacitive Touch Screen panel also helps supervisors monitor energy consumption, production quality, and equipment status, contributing to better process control and predictive maintenance.

Design flexibility is one of the biggest advantages of working with specialized Swiss Capacitive Touch Screen suppliers. Buyers can define not only the display size and resolution, but also the shape, printing, and surface treatment of the cover glass.

For example, a Capacitive Touch Screen can include printed logos, colored frames, and integrated capacitive keys or sliders around the active area. For outdoor or high‑brightness applications, the supplier may recommend a Capacitive Touch Screen with high‑transmission glass, anti‑reflection coatings, and a high‑brightness TFT backlight. In very harsh environments, a thicker front glass, special laminations, or even laminated safety glass can be used to protect the Capacitive Touch Screen and underlying display.

Industrial and medical applications require more than just a responsive Capacitive Touch Screen; they also demand compliance with environmental and regulatory requirements. Swiss suppliers are familiar with European standards and sector‑specific regulations, ensuring that the complete HMI, including the Capacitive Touch Screen, can pass relevant tests.

For outdoor, transportation, or factory environments, the Capacitive Touch Screen assembly often needs resistance to vibration, shock, humidity, and temperature extremes. Enclosures must provide ingress protection against dust and water, while the PCAP controller must handle electrical noise and long cable runs. In medical and laboratory equipment, the Capacitive Touch Screen and housing must withstand regular exposure to cleaning agents and disinfectants without degrading optical quality.

Swiss Capacitive Touch Screen suppliers generally offer several cooperation models tailored to different project sizes and levels of complexity. For small series or early‑stage projects, buyers can start with a standard kit that combines a TFT display, PCAP Capacitive Touch Screen, and controller board, allowing fast integration and testing.

For long‑term or high‑volume projects, the cooperation often evolves into a custom HMI design. In such cases the supplier's engineering team works closely with the OEM to define mechanical drawings, glass shapes, printing, connector types, and firmware settings for the Capacitive Touch Screen. After prototyping and validation, the Swiss partner can manage stable series production with defined testing procedures, documentation, and lifecycle management.

When choosing among Swiss Capacitive Touch Screen manufacturers and suppliers, global buyers should look beyond a simple price comparison. Important criteria include display and controller lifecycle, availability of long‑term replacements, and the supplier's track record in the relevant industry.

Support and communication are equally critical. A strong partner will offer early design reviews, Mechanical and Electrical drawings, and clear recommendations on how to integrate the Capacitive Touch Screen mechanically and electrically. Buyers should also confirm whether the supplier can help with EMC, safety, and environmental tests, since a Capacitive Touch Screen is often an essential part of the overall system's certification.

Future developments in Swiss Capacitive Touch Screen technology will likely focus on larger sizes, higher resolutions, and more advanced surface treatments. As industrial and medical devices become more sophisticated, operators will expect user experiences similar to consumer tablets and smartphones, but with the ruggedness and reliability of industrial equipment.

Integration with embedded computing, connectivity, and data analytics will also increase. Capacitive Touch Screen HMIs are becoming gateways to cloud systems, MES software, and predictive maintenance platforms. Swiss suppliers that combine strong Capacitive Touch Screen design with embedded hardware and software expertise will be in a strong position to support Industry 4.0 and smart manufacturing projects worldwide.

Switzerland has established itself as a specialized center for high‑quality Capacitive Touch Screen and HMI solutions, with companies such as SCHURTER, Advanced Silicon, DMB Technics, FORTEC Switzerland, and Simpex Electronic playing key roles in the ecosystem. These suppliers emphasize customized PCAP designs, long‑term lifecycle management, and strong engineering support, making Swiss Capacitive Touch Screen technology particularly attractive for industrial, medical, transportation, and high‑end commercial applications.

For global OEMs, system integrators, and manufacturers in sectors like abrasives and refractory materials, cooperating with Swiss Capacitive Touch Screen experts can significantly enhance machine interfaces, process visibility, and operator safety. By focusing on appropriate selection criteria and leveraging flexible cooperation models, buyers can secure robust Capacitive Touch Screen solutions that remain reliable and competitive over many years of demanding operation.

A Capacitive Touch Screen uses changes in an electrostatic field to detect touches, allowing precise and responsive multi‑touch operation. It is preferred in industrial projects because it offers excellent optical clarity, long mechanical life, and a flat, sealed glass surface that is easier to clean and more resistant to wear than mechanical buttons or resistive touch panels.

Yes, most Swiss suppliers can customize Capacitive Touch Screen modules by adjusting the sensor size, cover glass thickness, shape, printing, and controller firmware. They can also provide options such as optical bonding, anti‑glare or anti‑reflection treatments, integrated capacitive keys, and tailored mechanics to match the customer's housing and environmental requirements.

With appropriate sensor design and controller tuning, many Capacitive Touch Screen systems can be optimized to work with thin gloves and in environments exposed to moisture or dust. The front glass and housing can be designed to meet high ingress‑protection ratings, while firmware parameters are adjusted so the Capacitive Touch Screen distinguishes between intentional touches and water droplets or contaminants.

Capacitive Touch Screen interfaces are widely used in industrial automation, machine building, medical technology, laboratory equipment, public transportation, building automation, and premium retail or kiosk systems. These sectors demand reliable, long‑life HMIs where intuitive operation and compliance with European standards are crucial.

Overseas buyers should review each partner's technical capabilities, experience in similar applications, and long‑term component lifecycle policies. It is important to evaluate engineering support, documentation quality, sample availability, and the supplier's ability to handle prototyping, certification assistance, and stable mass production for the chosen Capacitive Touch Screen solution.

Top Capacitive Touch Display Manufacturers And Suppliers in Italy

Top Capacitive Touch Display Manufacturers And Suppliers in Spain

Top Capacitive Touch Display Manufacturers And Suppliers in Portugal

Top 7 Inch Hdmi Touch Screen Manufacturers And Suppliers in Vietnam

Top Capacitive Touch Display Manufacturers And Suppliers in Russia

Top Capacitive Touch Display Manufacturers And Suppliers in France

Top Capacitive Touch Display Manufacturers And Suppliers in Saudi Arabia

Top 7 Inch Hdmi Touch Screen Manufacturers And Suppliers in Turkey