Views: 222 Author: Wendy Publish Time: 2025-12-17 Origin: Site

Content Menu

● What Is a Capacitive Touch Screen?

● Why the UK Market Matters for Capacitive Touch Screen Buyers

● Core Applications of Capacitive Touch Screen Technology

● Technical Overview: How a Capacitive Touch Screen Works

● Typical Specifications of Industrial Capacitive Touch Screens

● Leading Capacitive Touch Screen Companies Serving the UK

>> Zytronic

>> FORTEC UK

>> Global Brands Strong in Capacitive Touch Screen Solutions

● How to Choose a UK Capacitive Touch Screen Partner

● Design Considerations for Industrial and Medical Capacitive Touch Screens

● Advantages of Capacitive Touch Screens Over Traditional Interfaces

● Future Trends in UK Capacitive Touch Screen Technology

● Working with a Chinese Capacitive Touch Screen and Component Partner

● FAQ

>> 1. Why should I choose a capacitive touch screen instead of a resistive one?

>> 2. Can a capacitive touch screen work with thick protective glass?

>> 3. Is a capacitive touch screen suitable for outdoor and public applications?

>> 4. How do I start a custom capacitive touch screen project with a UK supplier?

>> 5. What maintenance does a capacitive touch screen require in industrial settings?

The UK has become a dynamic hub for capacitive touch screen innovation, especially for industrial, medical, retail, and transportation applications that demand high reliability and customization. For buyers, engineers, and project managers, understanding the leading capacitive touch screen manufacturers and suppliers in the UK is essential for selecting the right partner for long-term projects.

A capacitive touch screen uses a transparent conductive layer to detect changes in an electrostatic field when a finger or conductive object touches the surface. Unlike resistive touch technology, a capacitive touch screen does not rely on pressure, which allows smooth multi‑touch gestures, excellent optical clarity, and longer mechanical life.

There are two main categories: surface capacitive and projected capacitive (PCAP) touch screens, with PCAP now dominating industrial and commercial markets due to its superior sensitivity, glove‑compatibility options, and design flexibility. A modern capacitive touch screen can support multiple simultaneous touch points, enabling advanced zoom, rotate, and multi‑user interfaces.

The United Kingdom has seen rapid growth in coated and projected capacitive touch screen solutions, driven by automation, digital signage, self‑service retail, and smart transportation projects. UK manufacturers and distributors of capacitive touch screen solutions combine local engineering know‑how with global production networks, ensuring robust supply chains and technical support close to European customers.

For overseas buyers, partnering with UK‑based capacitive touch screen experts offers advantages in regulatory compliance, fast communication, and experience with demanding industrial and medical standards. Many UK suppliers also specialize in custom capacitive touch screen solutions, including bespoke cover glass, bonding, and environmental protection for harsh or outdoor installations.

Capacitive touch screen technology is now embedded in almost every modern interface, from consumer devices to complex industrial systems. In the UK, several sectors are especially important for projected capacitive touch screen deployment:

- Industrial controls and factory automation HMIs and panel PCs, where capacitive touch screen interfaces replace mechanical buttons and switches.

- Medical devices and pharmaceutical equipment that require sealed, hygienic capacitive touch screen interfaces for easy cleaning and disinfection.

- Retail POS terminals, self‑checkout kiosks, and interactive digital signage featuring large‑format projected capacitive touch screen fronts.

- Transportation and ticketing, including rail, metro, and bus ticket machines with rugged, vandal‑resistant capacitive touch screens.

- Automotive and specialist vehicles using in‑dash capacitive touch screen displays and smart control panels.

Across these environments, a capacitive touch screen provides intuitive operation, long lifetime, and design flexibility that would be difficult to achieve with traditional mechanical controls.

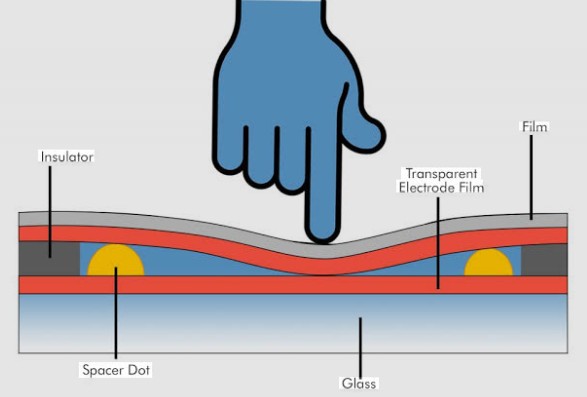

A projected capacitive touch screen typically consists of a sensor layer with patterned conductive traces, laminated to a cover glass and connected to a controller. The sensor creates a grid of electrodes that generate an electric field across the surface. When a finger or conductive stylus approaches, the local capacitance changes, and the controller measures this variation to determine the touch location.

Modern capacitive touch screen controllers apply sophisticated algorithms to filter noise, distinguish between intentional touches and interference, and support features like palm rejection. Firmware tuning is especially important in industrial and medical applications, where a capacitive touch screen must remain stable in the presence of electrical noise, grounding variations, or liquid on the surface.

Projected capacitive touch screen designs can also be optimized for:

- Operation with latex or thin work gloves.

- Water‑rejection or water‑tolerant detection modes.

- Thick cover glass that provides impact and vandal resistance.

- Curved or special‑shaped cover lenses for modern product design.

When choosing a capacitive touch screen for a UK‑based project, engineers evaluate key parameters that directly impact user experience and durability. Typical industrial projected capacitive touch screen specifications include:

- Size range from 7 inches for compact HMIs to 55 inches or more for kiosks and digital signage.

- Multi‑touch support, often with 2 to 10 or more independent touch points.

- Cover glass thickness between roughly 1.8 mm and 6 mm, with optional chemically strengthened or laminated glass for public use.

- Interface options such as USB, I2C, or serial that connect directly to embedded boards or PCs.

- Operating temperature ranges designed for industrial cabinets, outdoor kiosks, or vehicle cabins.

- Optical enhancements like anti‑glare, anti‑reflection, and anti‑fingerprint coatings to improve visibility.

By clarifying these requirements early, buyers ensure that the selected capacitive touch screen can withstand the mechanical, thermal, and environmental stresses of the intended application.

The UK ecosystem includes local manufacturers, engineering houses, and value‑added distributors focused on capacitive touch screen displays. While each company has its own strengths, together they provide a comprehensive supply chain for both standard and custom capacitive touch screen projects.

Zytronic is widely recognized as a specialist in projected capacitive touch sensors for demanding public and industrial environments. Its capacitive touch screen solutions are frequently used in gaming terminals, ticket machines, outdoor information kiosks, and interactive signage.

One key advantage of Zytronic's capacitive touch screen technology is the ability to operate reliably with thick, toughened cover glass and large screen sizes. This combination allows designers to create vandal‑resistant and weatherproof fronts without sacrificing sensitivity or multi‑touch capability. Zytronic's engineering team also provides extensive customization for sensor patterns, glass shapes, and printed graphics.

FORTEC UK focuses on display and touch solutions, providing projected capacitive touch screen components for industrial, medical, defence, and transportation projects. The company typically delivers fully engineered capacitive touch screen assemblies matched with TFT panels, optical bonding options, and mechanical integration support.

For customers building equipment with long life cycles, FORTEC UK places emphasis on stable supply, long‑term availability, and lifecycle management of capacitive touch screen modules. Engineers can collaborate with FORTEC to define cover glass thickness, surface treatments, and controller settings that match specific environmental and regulatory requirements in the UK and Europe.

Direct Insight provides embedded systems and display solutions that often incorporate capacitive touch screen interfaces. Instead of focusing on raw sensor manufacturing, the company helps OEMs integrate a chosen capacitive touch screen with single‑board computers, SOMs, and development kits.

This integration‑centric role is valuable for developers who need a complete embedded platform where the capacitive touch screen, display, and processing hardware are validated to work together. Direct Insight can help shorten development time by providing reference designs, drivers, and support for operating systems such as Linux or Windows on embedded platforms.

Touchscreens Direct operates as a UK reseller and integrator of interactive touch displays, offering a wide range of sizes and mounting options. Many of its products use projected capacitive touch screen technology to deliver responsive, multi‑touch interaction in meeting rooms, classrooms, retail spaces, and control rooms.

Because Touchscreens Direct works with multiple global brands, customers can choose from an extensive catalogue of capacitive touch screen monitors, open‑frame displays, and large interactive panels. The company also supports project specification, bracket and stand selection, and deployment planning for multi‑site rollouts.

Alongside UK‑based companies, several global players are heavily present in the UK market through distribution and integration partners. These brands include:

- Elo, known for robust projected capacitive touch screen monitors and components used in retail, hospitality, and signage.

- International OEMs that design custom capacitive touch screen modules and work with UK integrators to reach local customers.

For some projects, a combination of a global capacitive touch screen manufacturer and a local UK engineering partner provides an optimal balance between cost, performance, and support.

Choosing the right capacitive touch screen partner in the UK involves both technical and commercial considerations. Engineers and procurement teams should evaluate:

- Application experience: Suppliers with project history in similar environments (industrial plants, hospitals, public transport, etc.) understand the nuances of capacitive touch screen performance under real‑world conditions.

- Customization capability: The ability to design custom sensor patterns, cover glass, printing, and bonding ensures that the capacitive touch screen fits both mechanical and visual branding requirements.

- Lifecycle and logistics: Long‑term availability of the chosen capacitive touch screen, as well as buffer stock, shipping times, and after‑sales support, affect overall project risk.

- Certification expertise: For medical, automotive, or safety‑critical systems, a partner experienced with regional and international standards can streamline approval processes.

By examining these factors, buyers can narrow down which UK capacitive touch screen suppliers best match their technical targets and business constraints.

Industrial and medical applications impose specific challenges that designers must address when specifying a capacitive touch screen:

- Glove and tool operation: Many operators wear gloves, so the capacitive touch screen must either be tuned to detect gloved touches or combined with specific glove materials compatible with projected capacitive sensing.

- Liquid and contamination: In food, pharmaceutical, or outdoor environments, liquid and dust can interfere with detection. Firmware must distinguish droplets from real touches, and the capacitive touch screen should be easy to clean.

- EMC and electrical noise: Industrial panels frequently sit near motors, drives, or RF sources that generate noise. Proper grounding, shielding, and controller settings are essential for stable capacitive touch screen operation.

- Mechanical robustness: Thick, chemically strengthened glass, appropriate mounting, and sometimes additional protection like bezels are required to prevent breakage in public or high‑impact environments.

These issues are best addressed during early design reviews with a knowledgeable capacitive touch screen supplier, rather than at the end of development.

A capacitive touch screen brings practical benefits over membrane keypads, mechanical switches, and resistive touch panels:

- Enhanced user experience: Smooth gestures, fast response, and visually appealing glass surfaces make capacitive touch screen interfaces more intuitive and attractive.

- Improved reliability: With no mechanical contacts to wear out, a capacitive touch screen can withstand millions of actuations without degradation in feel.

- Better hygiene: A continuous, sealed glass surface is easier to clean and disinfect than keyboards or keypads with crevices, which is critical for medical and food industries.

- Design flexibility: Custom shapes, borderless fronts, and integrated lighting or logos allow manufacturers to differentiate their products and enhance brand recognition.

As users increasingly expect smartphone‑like interaction everywhere, capacitive touch screen controls have become the default choice for new equipment designs.

The capacitive touch screen sector in the UK is evolving alongside broader trends in human‑machine interfaces:

- Larger and curved displays: Designers are exploring curved glass and ultra‑wide formats, pushing capacitive touch screen technology into more immersive experiences.

- Higher durability and impact resistance: Advanced glass treatments and laminations are extending the use of capacitive touch screens into harsher outdoor and industrial scenarios.

- Integration with embedded AI: As edge computing grows, capacitive touch screen interfaces are combined with onboard analytics, gesture recognition, and predictive maintenance dashboards.

- Sustainability and lifecycle focus: Suppliers and customers are paying more attention to material choices, recyclability, and the total environmental impact of capacitive touch screen modules over their lifetime.

These innovations will further strengthen the role of capacitive touch screen solutions in UK manufacturing, transport, healthcare, and public infrastructure.

For many UK and European projects, combining local engineering with competitive Asian manufacturing can deliver excellent value. A Chinese company experienced in advanced components can:

- Provide high‑quality glass, conductive coatings, and electronic components that underpin reliable capacitive touch screen performance.

- Offer cost‑effective custom production runs, including specialized glass treatments and precision‑cut cover lenses.

- Collaborate with UK integrators and OEMs to match capacitive touch screen designs to mechanical housings, sealing gaskets, and front‑panel assemblies.

By aligning specifications, quality standards, and communication processes, such partnerships ensure that every capacitive touch screen delivered to UK customers meets both performance and budget expectations.

The UK has emerged as a strategic centre for capacitive touch screen engineering and integration, serving industrial, medical, retail, and transportation markets with advanced projected capacitive solutions. From specialist manufacturers and sensor designers to distributors and embedded‑system integrators, the UK ecosystem offers a full spectrum of capacitive touch screen expertise.

By carefully defining application requirements and working with experienced partners, buyers can select capacitive touch screen solutions that deliver the right combination of sensitivity, durability, hygiene, and visual appeal. As automation and digital transformation continue, capacitive touch screen technology will remain a core building block of modern human‑machine interaction across the UK and beyond.

A capacitive touch screen offers superior clarity, faster response, and true multi‑touch capability, while resistive screens rely on pressure and typically support only single‑touch input. For most modern industrial and commercial interfaces, the improved user experience of a capacitive touch screen justifies the small cost difference.

Yes. Modern projected capacitive touch screen sensors and controllers are designed to work through thick, toughened cover glass, often several millimetres thick. Proper sensor design and controller tuning ensure that the capacitive touch screen remains responsive even with vandal‑resistant or impact‑resistant glass.

A capacitive touch screen can be very effective outdoors and in public environments if designed correctly with appropriate glass thickness, sealing, and optical coatings. Many ticket machines, ATMs, and information kiosks use capacitive touch screen interfaces because they balance durability, visibility, and ease of use.

The best first step is to prepare basic requirements such as screen size, resolution, operating environment, glove use, and any specific regulatory needs. With this information, a UK capacitive touch screen supplier can propose suitable sensor, glass, and controller options, then develop samples and prototypes for evaluation.

Routine maintenance mainly consists of cleaning the glass surface with compatible agents and checking that seals and gaskets remain intact. Because a capacitive touch screen has no mechanical contacts, wear is minimal, and, with proper installation, the interface can operate for many years with only basic care.

Top Capacitive Touch Display Manufacturers And Suppliers in Italy

Top Capacitive Touch Display Manufacturers And Suppliers in Spain

Top Capacitive Touch Display Manufacturers And Suppliers in Portugal

Top 7 Inch Hdmi Touch Screen Manufacturers And Suppliers in Vietnam

Top Capacitive Touch Display Manufacturers And Suppliers in Russia

Top Capacitive Touch Display Manufacturers And Suppliers in France

Top Capacitive Touch Display Manufacturers And Suppliers in Saudi Arabia

Top 7 Inch Hdmi Touch Screen Manufacturers And Suppliers in Turkey