Views: 222 Author: Amanda Publish Time: 2026-01-14 Origin: Site

Content Menu

● Japan as a hub for custom touch screens

● Main types of Japanese custom touch suppliers

● Leading Japan‑based touch and display brands

● How global OEM partners like Reshine Display support Japan‑related projects

● Why OEMs combine Japanese engineering with Chinese custom manufacturing

● Technical foundations of custom touch modules

● Key selection factors for Custom Size Touch Screen Manufacturers and Suppliers in Japan

● Typical applications in the Japanese market

● How Reshine Display cooperates with Japanese‑focused projects

● Practical cooperation tips for overseas buyers

● FAQ

>> 2. How does Reshine Display support custom projects for the Japanese market?

>> 4. Are custom touch solutions cost‑effective compared to standard modules in Japan?

Japan has become one of the most important hubs in Asia for Custom Size Touch Screen Manufacturers and Suppliers, especially for high‑reliability applications such as industrial automation, medical devices, automotive electronics, and retail systems. For overseas OEMs and brand owners, understanding how Japanese Custom Size Touch Screen partners work—and how to cooperate with global OEM factories like Reshine Display—is crucial for building competitive touch‑enabled products.[1][2]

Japan's strong electronics ecosystem, precision manufacturing culture, and focus on quality create ideal conditions for Custom Size Touch Screen Manufacturers and Suppliers serving demanding vertical markets. Rapid adoption of digital transformation in factories, hospitals, and public spaces has driven a surge in interactive terminals, human–machine interfaces, and smart devices that depend on reliable, customized touch solutions.[3][1]

The Japanese government's “Society 5.0” vision encourages automation, robotics, and connected systems, further boosting demand for interactive displays and touch modules. As a result, both local manufacturers and global OEM partners are expanding their capabilities to offer tailored touch and TFT LCD modules that match Japanese standards for durability, usability, and long‑term availability.[2][4]

Japanese Custom Size Touch Screen Manufacturers and Suppliers can be broadly grouped into several categories, each playing a different role in the value chain. For project planners, understanding these categories is the first step toward building the right supplier mix.[1]

- Display and panel makers: Companies that design and manufacture LCD, OLED, and TFT display modules, often providing industrial, automotive, and specialized screens that can be combined with custom touch panels.[5]

- Industrial touch specialists: Suppliers focused on durable, high‑reliability panels optimized for harsh environments, with features like wide temperature ranges, high IP ratings, and robust front glass.[6]

- Integrated HMI and system providers: Solution houses that bundle displays, touch sensors, controllers, enclosures, and software into complete terminals for factories, transportation, retail, and public information systems.[1]

These groups frequently cooperate: a Japanese HMI integrator may select a local or global display module, then pair it with a custom sensor and cover glass designed by specialized Custom Size Touch Screen Manufacturers and Suppliers. This layered structure allows each participant to focus on core strengths while maintaining the quality expectations typical of the Japanese market.[3][1]

Several recognized Japanese brands provide the display and touch foundations used by integrators and global OEMs. They are particularly strong in mid‑to‑high‑end applications where reliability, documentation, and lifecycle support are non‑negotiable.[5][6]

Japan Display Inc. (JDI) is known for advanced LCD modules used in automotive, industrial, and specialty products, supplying high‑brightness, high‑contrast panels that can be combined with custom capacitive touch solutions. Industrial interfaces, in‑vehicle instrument clusters, and premium handheld devices commonly rely on such modules as the visual core while external Custom Size Touch Screen Manufacturers and Suppliers provide bespoke sensor and cover glass designs.[7][5]

DMC and similar companies focus on touch technologies, offering resistive and capacitive panels tailored to industrial and kiosk environments. Their panels may be integrated with display modules from JDI or other vendors, forming a rugged front end for operator panels, vending equipment, and information kiosks distributed across Japan.[6]

In many cases, Japanese HMI and kiosk integrators assemble complete terminals by sourcing panels and touch components from a mix of local and overseas Custom Size Touch Screen Manufacturers and Suppliers. This modular approach creates opportunities for factories like Reshine Display to act as OEM partners that deliver the customized touch and TFT LCD assemblies demanded by these system builders.[2][1]

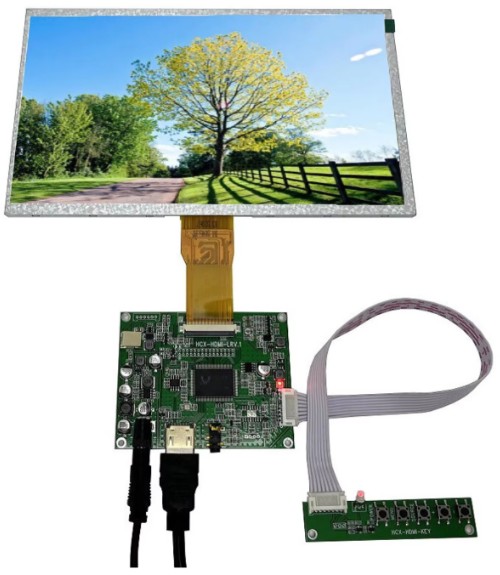

Reshine Display is a professional factory specializing in both standardized and custom touch screens and TFT LCD displays, offering OEM services to global brands, wholesalers, and equipment manufacturers. For projects that will be installed, integrated, or sold in Japan, Reshine Display functions as a flexible Custom Size Touch Screen Manufacturers and Suppliers partner capable of tailoring modules to Japanese engineering expectations.[8][2]

The product scope includes custom capacitive touch screens, resistive touch panels, and integrated TFT LCD modules ranging from small diagonals for handheld devices to larger formats for industrial and retail equipment. By combining touch sensors with TFT LCDs and optional bonding processes, Reshine Display delivers ready‑to‑assemble modules that system integrators can mount directly into their enclosures.[9][8]

Customization depth extends from size and aspect ratio to cover glass thickness, border design, printing, and mounting structure. Flexible printed circuit (FPC) layouts, interface definitions, brightness levels, and backlight configurations can also be adjusted, making Reshine Display one of the more adaptable Custom Size Touch Screen Manufacturers and Suppliers for Japanese‑focused OEM projects that need mechanical and optical optimization.[8][2]

A growing number of projects combine Japanese system architecture and certification processes with custom modules sourced from specialized OEM factories abroad. In this model, Japanese engineers define the functional requirements, safety standards, and user experience, while overseas Custom Size Touch Screen Manufacturers and Suppliers translate those requirements into optimized hardware.[2][1]

This approach balances cost and performance: Japanese integrators can maintain local control over design, field support, and branding, while leveraging cost‑effective, high‑mix production capabilities from OEM factories like Reshine Display. For many applications, especially industrial and retail, this combination delivers better lifetime value than relying purely on generic off‑the‑shelf panels or fully domestic custom builds.[10][8][1][2]

The collaboration also supports faster iteration cycles. Once a prototype design is approved, the OEM factory can quickly adjust sensor patterns, cover shapes, or interface options based on feedback from Japanese field tests. As Custom Size Touch Screen Manufacturers and Suppliers fine‑tune these modules, Japanese integrators gain differentiated hardware that matches their application environment exactly.[8][2]

Custom touch modules combine several critical layers that Custom Size Touch Screen Manufacturers and Suppliers must engineer as a unified system. Understanding these layers helps OEM and ODM customers communicate clearly with suppliers.[8]

- Cover lens: Usually glass or durable plastic, providing mechanical protection, optical appearance, and any printed elements such as logos or borders.[8]

- Touch sensor: Often based on projected capacitive or resistive technologies, using specific ITO patterns or wire structures to detect touch positions and gestures.[11][8]

- Controller electronics: ICs and firmware that interpret sensor signals and communicate with the host system over interfaces like I⊃2;C, USB, or SPI.[11][8]

- Display module: TFT LCD or other display technology providing brightness, resolution, contrast, and viewing angles tailored to the application.[9][5]

- Bonding and assembly: Processes such as optical bonding or air‑gap bonding to attach the touch sensor to the display while managing reflections, durability, and thermal performance.[9][8]

In Japan, where use cases include outdoor kiosks, factory automation, and medical systems, these layers must work together reliably in challenging conditions. As a result, Custom Size Touch Screen Manufacturers and Suppliers that serve the Japanese market must implement tight process control, thorough testing, and detailed documentation.[3][1][2][8]

Selecting the right Custom Size Touch Screen Manufacturers and Suppliers for Japan‑linked projects requires evaluating both technical and commercial aspects in detail.[1][8]

Technical fit is paramount: decision‑makers should assess temperature range, brightness, contrast, and viewing angle requirements alongside touch technology, controller compatibility, and interface options. For applications such as outdoor ticket machines or industrial HMIs, wide temperature support, high luminance, and robust touch performance under water or glove operation are often mandatory.[6][11][3][1]

Reliability and testing are equally important. Suppliers should be able to perform temperature cycling, humidity tests, vibration, ESD, and lifetime testing consistent with industrial or automotive norms common in Japan. When Custom Size Touch Screen Manufacturers and Suppliers can share detailed test reports and quality records, Japanese OEMs gain confidence that modules will perform consistently over long product lifetimes.[9][1][8]

Customization capability determines whether the supplier can deliver modules that truly match enclosure designs and user experience goals. This includes adjusting cover glass thickness, edge shapes, printed borders, mechanical mounting features, and even fine details like cable exit direction or connector choice, all of which matter to Japanese integrators who value neat mechanical integration.[11][2][8]

Finally, lifecycle and supply stability are critical for markets where equipment must remain in service for many years. Both local and overseas Custom Size Touch Screen Manufacturers and Suppliers should provide clear roadmaps, EOL policies, and second‑source strategies so that Japanese customers can plan long‑term product support.[7][5][2][1]

Custom touch modules and TFT LCD assemblies supplied by Custom Size Touch Screen Manufacturers and Suppliers serve numerous sectors in Japan, each with its own design priorities.[3][1]

Industrial automation and robotics require rugged modules that withstand vibration, dust, oil, and temperature extremes while remaining readable under bright factory lighting. In these environments, manufacturers often select projected capacitive sensors with glove support, high‑brightness TFT LCDs, and thick cover glass designs that Custom Size Touch Screen Manufacturers and Suppliers can tailor to panel‑mount enclosures.[3][9][8]

Automotive and transportation applications, including in‑vehicle displays and station terminals, demand high contrast, careful EMC behavior, and long‑term availability, as vehicles and infrastructure typically have long life cycles. Modules must remain legible in both direct sunlight and low‑light situations, pushing Custom Size Touch Screen Manufacturers and Suppliers to optimize backlight design and optical bonding.[4][5][9]

Medical and laboratory systems prioritize hygiene, precision, and clear visualization of data. Custom modules in this sector often use smooth, easy‑to‑clean surfaces, high‑resolution TFT LCDs, and touch firmware tuned for precise operation, all coordinated by experienced Custom Size Touch Screen Manufacturers and Suppliers.[11][1][8]

Retail, ticketing, and public information systems rely on mid‑to‑large‑format touch displays able to handle heavy daily use by a wide range of users. Here, Japanese integrators frequently work with global partners to source cost‑effective yet robust custom modules, combining local design with overseas OEM production.[12][2][1]

Reshine Display supports projects connected to Japan by acting as a behind‑the‑scenes OEM provider for Custom Size Touch Screen Manufacturers and Suppliers needs. Japanese brands, distributors, and system integrators can define specifications and mechanical constraints, while Reshine Display engineers design and deliver matching modules.[2][8]

The company's OEM and ODM services cover the full path from concept to mass production, including schematic review, mechanical matching, sensor and cover lens design, and selection of TFT LCD characteristics. This makes it easier for customers to turn system‑level requirements into manufacturable touch and display modules that align with Japanese standards for quality and usability.[2][8]

Reshine Display's technology coverage includes capacitive and resistive technologies, compatible with TFT LCDs in many sizes and resolutions. By offering one‑stop Custom Size Touch Screen Manufacturers and Suppliers services, the factory allows Japanese‑related projects to consolidate sourcing, reduce integration risk, and streamline communication during development and ramp‑up.[9][2][8]

Global logistics capabilities enable modules to be shipped to Japanese EMS providers or directly to system assembly plants with appropriate packaging, labeling, and documentation. This combination of engineering support, customization depth, and delivery reliability is especially valuable for overseas buyers serving the Japanese market through local partners.[1][2][9]

Overseas OEMs and brands that plan to work with Custom Size Touch Screen Manufacturers and Suppliers for Japan‑related deployments can improve outcomes by preparing structured technical and commercial information.[1][8]

On the technical side, clear documentation of target use cases, environmental conditions, and interface expectations helps suppliers propose suitable module architectures. Sharing mechanical drawings, panel cutout dimensions, and information about mounting methods allows Custom Size Touch Screen Manufacturers and Suppliers to optimize cover glass shape, thickness, and FPC routing.[11][8]

On the commercial side, realistic forecasts and phase‑in schedules make it easier for suppliers to plan material procurement and capacity reservation, which is crucial for long‑lifecycle markets. When both Japanese integrators and overseas OEM factories share transparent schedules and risk assessments, they can jointly manage lead times and minimize supply disruptions.[2][1]

Japan is one of the most demanding and opportunity‑rich markets for interactive hardware, making it a strategic destination for Custom Size Touch Screen Manufacturers and Suppliers that serve industrial, medical, automotive, and retail sectors. By combining the strengths of Japanese system design and integration with flexible OEM factories like Reshine Display, global brands and equipment manufacturers can obtain tailored touch and TFT LCD modules that meet strict performance and reliability expectations. For any project targeting Japan, choosing responsive, technically capable Custom Size Touch Screen Manufacturers and Suppliers and building cooperative relationships across borders are essential to achieving long‑term success.[3][8][1][2]

The biggest advantages are precise mechanical fit, optimized optical performance, and the ability to align touch behavior with local usage patterns such as glove operation, outdoor visibility, and accessibility. Custom modules also help Japanese integrators and global OEMs reduce rework, shorten assembly times, and differentiate their products with unique front‑panel designs and user interfaces.[8][1][2]

Reshine Display offers OEM engineering from schematic review and mechanical matching to sensor design, cover customization, and selection of TFT LCD parameters tailored to the customer's application. As one of the flexible Custom Size Touch Screen Manufacturers and Suppliers, the factory can handle low‑to‑medium pilot runs and then scale to mass production for systems installed in Japan.[9][2][8]

Typically, engineers should prepare desired diagonal size, active area, resolution, brightness, viewing angle needs, operating temperature range, interface type, and touch technology preference. It is also important to share enclosure drawings, front‑panel thickness, and any special requirements like anti‑reflection treatment, anti‑fingerprint coating, or support for water‑drop and gloved operation so that Custom Size Touch Screen Manufacturers and Suppliers can design an optimal stack.[6][11][8]

While unit prices for custom modules can be higher than typical off‑the‑shelf parts, total system cost often decreases because the module fits perfectly, reduces mechanical compromises, and minimizes field failures. Working with experienced Custom Size Touch Screen Manufacturers and Suppliers such as Reshine Display allows design teams to optimize BOMs, assembly steps, and lifecycle support, which is especially important in the high‑quality Japanese market.[10][1][2][8]

Lead time depends on complexity, but a typical cycle from requirements confirmation to first article samples may range from several weeks to a few months for sophisticated industrial or medical modules. After samples are approved and local testing in Japan is complete, mass production schedules are defined jointly by the customer and the chosen Custom Size Touch Screen Manufacturers and Suppliers, including OEM factories like Reshine Display that specialize in scaling production.[11][1][2][8]

[1](https://www.reshine-display.com/top-custom-touch-screen-manufacturers-and-suppliers-in-japan.html)

[2](https://www.reshine-display.com)

[3](https://www.6wresearch.com/industry-report/japan-industrial-touchscreen-display-market)

[4](https://www.linkedin.com/pulse/japan-interactive-touch-screen-display-market-size-2025-csypf)

[5](https://www.j-display.com/en/)

[6](https://www.dush.co.jp/english/product/)

[7](https://www.edgeelectronics.com/Japan-Display-Inc/manufacturer.html)

[8](https://www.reshine-display.com/custom-touch-screen-display.html)

[9](https://www.reshine-display.com/products/digital-tft-lcd.html)

[10](https://touchscreenmfg.com)

[11](https://newhavendisplay.com/custom-solutions/custom-touchscreen-display-solutions/)

[12](https://www.thebusinessresearchcompany.com/report/retail-touch-screen-display-global-market-report)

Top Industrial Capacitive Touch Screen Manufacturers and Suppliers in USA

Top Industrial Capacitive Touch Screen Manufacturers and Suppliers in Europe

Top 10 Industrial Capacitive Touch Screen Manufacturers in China

Top Custom Size Touch Screen Manufacturers and Suppliers in Australia

Top Custom Size Touch Screen Manufacturers and Suppliers in Switzerland

Top Custom Size Touch Screen Manufacturers and Suppliers in South Korea

Top Custom Size Touch Screen Manufacturers and Suppliers in Japan

Top Custom Size Touch Screen Manufacturers and Suppliers in Italy