Views: 222 Author: Wendy Publish Time: 2026-01-09 Origin: Site

Content Menu

● Why South Korea for Custom Touch Screen Sourcing?

● Main Types of Custom Touch Screen Suppliers in South Korea

● Touch and Displays Co., Ltd. (Touch & Display)

● EDVision – Industrial Touch Monitors and Panel PCs

● Display and Life (DAL) – Professional Display Manufacturer

● Seong‑Ji Industrial Co., Ltd. – Touch Screen Panels and Components

● Other Relevant Korean Display and Touch Companies

● Core Custom Touch Screen Technologies in South Korea

● Key Application Sectors for Korean Custom Touch Screen Solutions

>> Industrial Automation and Smart Factories

>> Kiosks, Smart Retail, and Smart City Projects

>> Transportation and Public Transit

>> Medical Devices and Healthcare

● How to Select a South Korean Custom Touch Screen Partner

>> Define Technical Requirements Clearly

>> Evaluate Mechanical and Environmental Needs

>> Check Quality Systems and Certifications

● Typical Specification Flow for a Custom Touch Screen Project

● Cooperation Models: Combining Korean Modules With Global Integration

● Practical Tips for Overseas Buyers

● FAQ – Custom Touch Screen Sourcing in South Korea

>> (1) How do I choose between PCAP and resistive Custom Touch Screen solutions?

>> (2) What information should I include in an RFQ for a Korean Custom Touch Screen supplier?

>> (3) How long does it usually take to develop and deliver a Custom Touch Screen?

>> (4) Can Korean suppliers provide complete Custom Touch Screen systems, not just panels?

>> (5) How can I control total cost when sourcing Custom Touch Screen products from South Korea?

South Korea is a global leader in Custom Touch Screen technologies thanks to its strong display industry, mature electronics ecosystem, and export‑oriented manufacturers. For overseas OEMs in industrial automation, kiosks, medical devices, transportation, and smart retail, Korean Custom Touch Screen manufacturers and suppliers offer a balance of high performance, flexible customization, and competitive cost.

South Korea hosts major display and touch technology companies that support stable supply, long product lifecycles, and advanced optical solutions for Custom Touch Screen projects. This environment is ideal for global buyers who need Custom Touch Screen products with strict reliability, certification, and volume scalability.

South Korea has built a robust ecosystem around LCD, OLED, and industrial monitors, making it easier to integrate Custom Touch Screen modules into complete HMI systems. Industrial users, system integrators, and equipment manufacturers can all find partners that understand complex requirements for long‑life industrial and commercial projects.

Korean suppliers are also highly export‑oriented and accustomed to serving overseas customers with OEM/ODM services, English documentation, and professional after‑sales support. This makes South Korea attractive for global buyers who need Custom Touch Screen solutions that combine technical depth with reliable delivery and lifecycle planning.

Different categories of suppliers play specific roles in the Korean Custom Touch Screen ecosystem. Understanding these categories helps buyers choose the right partner for each project.

- Industrial monitor and panel PC manufacturers focused on rugged environments and specialized mounting or enclosure requirements for Custom Touch Screen devices.

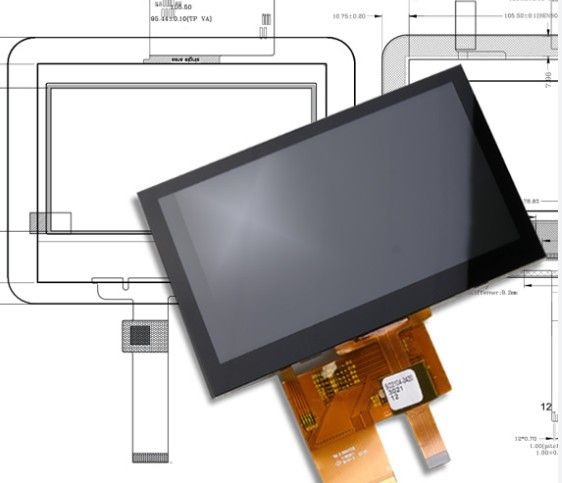

- Display and touch module manufacturers that supply integrated LCD/OLED and touch assemblies for OEM integration.

- Touch panel and component specialists producing PCAP sensors, touch screen panels, and related components that form the core of many Custom Touch Screen solutions.

- System integrators and kiosk builders that deliver complete Custom Touch Screen kiosks, terminals, and digital signage systems with software and mechanical design included.

For many projects, buyers cooperate with more than one type of supplier, such as using a Korean module manufacturer together with local enclosure and integration partners.

Touch and Displays Co., Ltd. is a Korean manufacturer focusing on touch screen monitors, Custom Touch Screen solutions, all‑in‑one systems, and industrial touch panel PCs. The company combines design, engineering, and manufacturing capabilities in‑house, offering OEM and ODM services to global customers.

Its product range typically covers industrial monitors, panel‑mount and open‑frame PCAP monitors, Android‑based advertising displays, and Custom Touch Screen panel PCs for factories, retail, and public spaces. By working closely with customers on mechanical drawings, interface requirements, and environmental specifications, Touch & Display helps implement Custom Touch Screen devices that are ready for installation in production lines, kiosks, or control rooms.

EDVision positions itself as a major industrial monitor provider with hundreds of standard models and extensive customization capability. This makes it highly relevant for industrial and transportation projects where Custom Touch Screen solutions must withstand vibration, dust, humidity, and temperature extremes.

The company offers industrial monitors, touch monitors, and panel PCs in various sizes and formats, and can adapt brightness, connectors, front bezels, and enclosures according to customer drawings. For overseas buyers, EDVision is particularly useful when there is a need for a rugged Custom Touch Screen platform that can be built into control cabinets, vehicle dashboards, or outdoor terminals.

Display and Life (DAL) is a professional display manufacturer that focuses on LCD and OLED modules, providing value‑added processes to enhance performance and reliability. While DAL is not purely a touch company, its displays often form the foundation for high‑quality Custom Touch Screen solutions.

When a project demands very specific display characteristics such as brightness, viewing angle, color performance, or wide temperature operation, buyers can combine DAL's professional displays with appropriate PCAP sensors and controllers. This approach creates Custom Touch Screen modules tailored to demanding environments like outdoor signage, industrial machines, or specialized medical equipment.

Seong‑Ji Industrial Co., Ltd. supplies touch screen panels (TSPs), sub‑assemblies, and IoT‑related components. Its experience in touch sensor and module production helps customers build compact and efficient Custom Touch Screen devices.

Seong‑Ji can support Custom Touch Screen projects that need specific sensor shapes, borders, or bonding methods, including integration into small handheld devices or compact terminals. This is especially relevant for IoT gateways, smart meters, and portable equipment where the Custom Touch Screen must be both space‑efficient and robust.

A broader set of Korean electronics and display companies also contributes to the Custom Touch Screen ecosystem. Some focus on large‑format displays and digital signage, while others specialize in niche industrial or commercial markets.

Panel manufacturers provide high‑quality TFT‑LCD and OLED displays that can be combined with PCAP overlays to create Custom Touch Screen signage, video walls, and interactive information boards. Additional firms offer digital signage systems, video walls, or interactive displays that can be adapted for Custom Touch Screen use in retail, corporate, or transportation environments.

By combining these resources, OEMs can design Custom Touch Screen solutions that range from small 4‑inch HMIs to large interactive walls exceeding 80 inches in diagonal size.

South Korean suppliers support multiple touch technologies, with projected capacitive (PCAP) dominating new Custom Touch Screen designs. However, other technologies still play a role in specific scenarios.

- PCAP Custom Touch Screen: Multi‑touch capability, high transparency, and a flat glass surface make PCAP ideal for modern, high‑end interfaces. It suits kiosks, industrial HMIs, POS terminals, medical monitors, and public terminals.

- Resistive Custom Touch Screen: Sometimes used in legacy or special environments where stylus input, certain EMI conditions, or specific controller compatibility is required.

- Other technologies: Infrared (IR), surface acoustic wave, and optical solutions for certain large‑format or special‑purpose Custom Touch Screen systems.

When specifying a Custom Touch Screen, buyers should evaluate glove usage, water exposure, EMI conditions, optical needs, and front‑glass impact resistance to decide which technology is most appropriate.

In industrial automation, Custom Touch Screen panel PCs and monitors serve as the front end for PLCs, SCADA systems, and MES dashboards. Korean suppliers provide rugged designs with sealed front surfaces, high brightness, and flexible mounting options.

Custom Touch Screen devices used on factory floors often require extended lifecycles, so Korean manufacturers typically support long‑term availability and stable bill‑of‑material control. This helps OEMs maintain consistent interfaces on machinery sold over many years.

Ticketing machines, self‑service kiosks, interactive directories, and public information terminals all rely on Custom Touch Screen interfaces. Korean suppliers are experienced in designing high‑brightness, vandal‑resistant, and weather‑resistant configurations for indoor and outdoor installations.

Smart city projects often integrate Custom Touch Screen systems into bus stops, subway stations, and public squares. In such cases, special attention must be paid to ingress protection, anti‑reflection coatings, and thermal management for outdoor conditions.

Custom Touch Screen solutions in transportation include driver HMIs, passenger information panels, and ticket vending systems. Korean suppliers can provide monitors and touch modules designed to withstand shock, vibration, and wide temperature ranges common in rail and road environments.

Additional requirements, such as transport‑specific certifications and electromagnetic compatibility, must be considered at the specification stage. Close cooperation between the vehicle integrator and the Custom Touch Screen manufacturer is critical for success.

Hospitals and clinics require Custom Touch Screen interfaces for diagnostic equipment, patient monitors, and information terminals. Korean manufacturers with appropriate quality systems can support medical‑grade displays and PCAP solutions that meet hygiene, brightness, and image quality requirements.

In these applications, Custom Touch Screen design must consider cleaning chemicals, frequent disinfection, and compatibility with gloves. Smooth glass surfaces and sealed designs help ensure long‑term reliability in medical environments.

The first step in selecting a Custom Touch Screen partner in South Korea is to define the technical needs as precisely as possible. This includes size, resolution, brightness, contrast, viewing angle, and operating temperature for the display itself.

On the touch side, buyers should specify whether the Custom Touch Screen should support glove use, water rejection, palm rejection, or specific multi‑touch gestures. Clarifying controller interface requirements (USB, I2C, RS‑232) early in the process prevents integration problems later.

Next, mechanical and environmental factors must be considered. Decisions about open‑frame, panel‑mount, or fully enclosed housings will influence which Korean suppliers are most suitable.

If the Custom Touch Screen is used in harsh conditions, buyers should set clear targets for ingress protection rating, vibration resistance, impact resistance, and operating temperature. Suppliers can then propose glass thickness, mounting structures, and sealing methods that match these requirements.

For industries such as medical devices, transportation, or heavy industry, it is important to verify quality systems and certifications. Buyers should check for ISO certifications, industry‑specific approvals, and documented reliability test results.

A good Custom Touch Screen partner will be transparent about its test processes and provide clear documentation such as test reports, MTBF estimates, and component traceability. This helps OEMs meet their own regulatory obligations and support end‑customer audits.

A structured specification and development flow reduces risk and speeds up time‑to‑market for Custom Touch Screen projects.

1. Application definition: Clarify where and how the Custom Touch Screen will be used, expected lifetime, and target shipment volume.

2. Display requirements: Decide on diagonal size, resolution, brightness, contrast, viewing angle, and any special color or sunlight readability needs.

3. Touch and cover glass: Choose PCAP or another technology, define glass thickness, logo and border printing, surface treatments (anti‑glare, anti‑reflection), and mechanical strength.

4. Mechanical integration: Provide 2D drawings or 3D files showing cut‑outs, mounting holes, bezel design, and required IP rating.

5. Interfaces and electronics: Specify input interfaces (HDMI, DisplayPort, LVDS, eDP), touch controller interface, and any extra IO or embedded computing requirements.

6. Prototyping and testing: Approve samples, perform functional testing, environmental testing, and pre‑compliance checks where necessary.

7. Mass production and lifecycle planning: Finalize production schedule, safety stock arrangements, and lifecycle management strategy for the Custom Touch Screen product.

Many OEMs and integrators use a hybrid sourcing model to balance quality, flexibility, and cost. In this approach, Korean companies supply the critical Custom Touch Screen modules, while enclosures, cabling, and final integration may be handled in other regions.

For example, a Korean manufacturer might supply a 15‑inch PCAP Custom Touch Screen module with bonded cover glass and controller, while a partner in another country builds the metal housing, power electronics, and mounting hardware. This strategy enables OEMs to leverage Korean expertise in display and touch while optimizing other parts of the hardware chain.

Additionally, some buyers work with Korean firms that offer full systems but request partial customization, such as changing front glass printing or enclosure color. This reduces development time compared to fully bespoke designs while still achieving a branded Custom Touch Screen appearance.

Overseas buyers can improve cooperation with Korean Custom Touch Screen suppliers by following a few practical guidelines.

- Provide detailed RFQs with mechanical drawings, photos, and clear descriptions of the target application.

- Share any relevant standards or certifications early, including EMC, safety, medical, or transportation requirements.

- Be realistic about sample and mass production lead times, especially for complex Custom Touch Screen designs.

- Discuss long‑term support and last‑time‑buy arrangements to protect product lifecycles.

- Consider using standard sizes where possible to reduce tooling costs and ensure fast availability of replacement Custom Touch Screen modules.

Communication quality is crucial: timely feedback on samples and clear documentation of changes will help keep the project under control and avoid delays.

South Korea provides a strong foundation for Custom Touch Screen sourcing, combining advanced display technology, industrial monitor expertise, and specialized touch panel production. By understanding the different supplier types—from industrial monitor makers and panel PC vendors to display manufacturers and touch panel specialists—buyers can select partners that match their technical and commercial needs.

With clear specifications, careful evaluation of mechanical and environmental requirements, and well‑planned cooperation models, overseas OEMs can implement reliable, high‑performance Custom Touch Screen solutions for industrial automation, transportation, medical, smart retail, and smart city applications. Working with Korean manufacturers also makes it easier to manage long‑term product availability and maintain consistent user experiences across global equipment portfolios.

PCAP Custom Touch Screen technology is usually preferred for modern applications because it supports multi‑touch, offers high transparency, and allows flat, attractive glass surfaces. Resistive touch may still be used for some legacy systems or specific environments, but most new industrial, medical, and kiosk projects choose PCAP for long‑term flexibility and better user experience.

A strong RFQ should include display size, resolution, brightness, mounting method, touch technology, cover glass details, operating temperature, and environmental conditions. Adding mechanical drawings, existing product photos, and required certifications helps Korean manufacturers design accurate Custom Touch Screen solutions and quote realistic prices and lead times.

Lead times vary with complexity, but many projects require several weeks for sample design and production, followed by testing and adjustments before mass production. Simple Custom Touch Screen configurations based on standard designs can be delivered faster, while highly customized or certified products may need longer development and validation cycles.

Yes, many Korean companies offer complete systems that combine display, touch, housing, electronics, and embedded computing. This turnkey approach is ideal when buyers want a ready‑to‑install Custom Touch Screen monitor, panel PC, kiosk, or terminal without managing multiple hardware vendors and integration steps.

To control cost, buyers can standardize key sizes and interfaces across multiple models, reduce excessive customization, and combine Korean module sourcing with cost‑effective local integration. Early discussions about target price levels, expected volumes, and lifecycle planning also help suppliers propose balanced Custom Touch Screen designs that meet both technical and commercial objectives.

Top Capacitive Touch Display Manufacturers And Suppliers in Italy

Top Capacitive Touch Display Manufacturers And Suppliers in Spain

Top Capacitive Touch Display Manufacturers And Suppliers in Portugal

Top 7 Inch Hdmi Touch Screen Manufacturers And Suppliers in Vietnam

Top Capacitive Touch Display Manufacturers And Suppliers in Russia

Top Capacitive Touch Display Manufacturers And Suppliers in France

Top Capacitive Touch Display Manufacturers And Suppliers in Saudi Arabia

Top 7 Inch Hdmi Touch Screen Manufacturers And Suppliers in Turkey