Views: 222 Author: Wendy Publish Time: 2026-01-09 Origin: Site

Content Menu

● Why Spain for Custom Touch Screen Sourcing

● Types of Custom Touch Screen Suppliers in Spain

● Representative Custom Touch Screen Players Linked to Spain

● Core Custom Touch Screen Technologies

● Key Application Sectors in Spain

● Typical Customization Options for Spanish Projects

● Cooperation Models with Spanish Custom Touch Screen Suppliers

● How Chinese OEMs and Integrators Fit In

● Practical Selection Checklist for Custom Touch Screen Projects in Spain

● Typical Project Workflow with a Custom Touch Screen Partner

● Design Tips for Long‑Life Custom Touch Screen HMIs

● Using Custom Touch Screen Solutions in Abrasives and Refractory Equipment

● Integration and After‑Sales Considerations

● FAQ About Custom Touch Screen Solutions in Spain

>> (1) How long do Custom Touch Screen products usually remain available?

>> (2) What information should I prepare before requesting a Custom Touch Screen quotation?

>> (3) Can Custom Touch Screen panels be used with gloves and in dusty industrial environments?

>> (4) How do Custom Touch Screen suppliers handle branding and industrial design?

>> (5) Are there minimum order quantities (MOQs) for Custom Touch Screen projects?

Spain is becoming an attractive sourcing destination for Custom Touch Screen solutions used in industrial automation, kiosks, transport, and digital signage projects across Europe and Latin America. Spanish manufacturers and engineering firms combine EU‑level quality with flexible customization, while many projects are implemented together with global display and HMI partners.[1]

This guide explains the Custom Touch Screen ecosystem in Spain, profiles representative Custom Touch Screen manufacturers and suppliers, and gives practical selection tips for long‑term, high‑reliability projects. It also shows how buyers can integrate Spanish and international Custom Touch Screen resources with cost‑effective Chinese OEM manufacturing and assembly.[1]

Spain has a growing cluster of companies focused on displays, HMIs, and electronic integration, serving sectors such as transportation, automotive, retail, and public information systems. Many of these firms specialize in sunlight‑readable displays and rugged Custom Touch Screen HMIs for harsh environments.[1]

For global buyers, Spain's EU location simplifies certification, logistics, and after‑sales service for Custom Touch Screen deployments across Europe. At the same time, Spanish HMI specialists increasingly cooperate with Asian factories to balance engineering depth with competitive pricing for Custom Touch Screen projects.[1]

Different categories of suppliers support the Custom Touch Screen value chain in Spain. Understanding these roles helps buyers design a sourcing strategy that fits project volume, complexity, and budget.[1]

- Industrial HMI panel manufacturers focusing on rugged Custom Touch Screen panel PCs and operator terminals for factories, energy, and infrastructure.

- Display and HMI design houses providing engineering, prototyping, and optical bonding for Custom Touch Screen display assemblies.

- EMS (electronics manufacturing services) companies integrating Custom Touch Screen modules into finished devices such as kiosks, ticketing machines, or medical systems.

- International PCAP and Custom Touch Screen specialists supporting Spanish projects with large‑size sensors, controllers, and firmware tuning.

Several companies with operations in or closely serving Spain illustrate the capabilities available for Custom Touch Screen projects.[1]

- Spanish HMI panel brands that focus on industrial Custom Touch Screen panels and rugged automation terminals for OEM machinery and process plants.[1]

- European display specialists that support Spanish digital signage and kiosk projects with Custom Touch Screen display systems optimized for 24/7 operation.[1]

- Iberian PCAP manufacturers supplying Custom Touch Screen solutions used by OEMs and integrators across the regional market, including Spain.[1]

- European PCAP suppliers providing custom open‑frame monitors, touch modules, and firmware tuning for OEM Custom Touch Screen applications in transport and industry.[1]

These players often cooperate with Chinese factories that produce sensors, cover glass, and bonded assemblies, creating hybrid supply chains for Custom Touch Screen systems.[1]

Modern Custom Touch Screen solutions used in Spain rely mainly on projected capacitive (PCAP) technology for mid‑to‑large sizes, with resistive options still used in some cost‑sensitive or gloved environments. PCAP Custom Touch Screen panels offer multi‑touch, high transparency, and a smooth glass surface suitable for professional HMIs and kiosks.[1]

Custom Touch Screen stacks typically combine a glass or film sensor, cover glass with printing and logo, a display module, and firmware‑tuned controller. Additional options such as anti‑glare or anti‑reflection coatings, sunlight‑readable backlights, and optical bonding improve outdoor readability for Spanish transport and public information projects.[1]

Custom Touch Screen deployments in Spain cover both industrial and public‑facing sectors.[1]

- Industrial automation and machinery: Custom Touch Screen HMIs control production lines, packaging machines, and process equipment, often requiring IP‑rated enclosures and glove‑friendly operation.[1]

- Transportation and ticketing: Sunlight‑readable Custom Touch Screen displays are used in on‑board systems, ticket kiosks, and information totems in buses, trains, and metros.[1]

- Retail and digital signage: Interactive displays, POS terminals, and wayfinding kiosks rely on Custom Touch Screen solutions tailored to branding and environment.[1]

- Medical and laboratory equipment: Sealed Custom Touch Screen interfaces support infection control while providing precise input in clinical settings.[1]

Custom Touch Screen projects serving Spanish customers commonly involve multiple customization layers.[1]

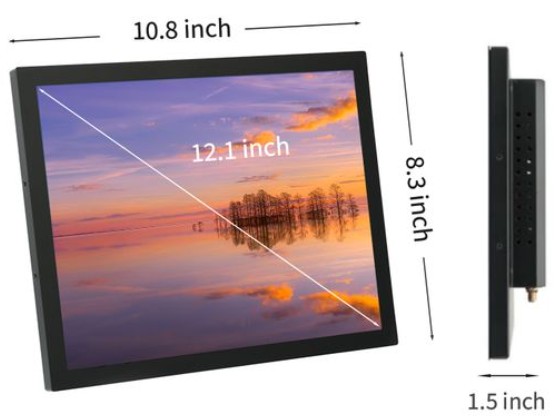

- Size and aspect ratio: From small handheld sizes to large 24‑inch and above panels, with both standard and fully custom formats for kiosks and control panels.

- Cover glass design: Custom shapes, thickness, logo printing, and colored borders to match each customer's product identity and mechanical envelope.

- Touch performance: Controller tuning for finger, glove, and water rejection, plus adjustment for different protective covers and laminations on the Custom Touch Screen.

- System integration: Open‑frame Custom Touch Screen monitors, panel PCs, and fully assembled kiosks with specific interfaces and mounting standards for easy installation.

These options allow OEMs to differentiate their products while using proven Custom Touch Screen building blocks.[1]

When working with Spanish or Iberian Custom Touch Screen suppliers, buyers usually select one of three cooperation models.[1]

- Component‑level supply, where the partner provides Custom Touch Screen sensors or modules and the OEM handles final integration and housing design.

- Semi‑finished open‑frame monitors, where suppliers deliver Custom Touch Screen monitors ready for mounting inside kiosks, cabinets, or machine panels.

- Turnkey HMI systems, in which Spanish and European partners provide complete Custom Touch Screen panel PCs or kiosk systems including electronics, software image, and enclosure.

This flexibility allows cost‑sensitive customers to keep mechanical work in‑house while relying on professional Custom Touch Screen engineering for the critical interface. For high‑value or safety‑critical projects, turnkey Custom Touch Screen HMIs simplify certification and lifecycle management.[1]

Many international projects combine European engineering with Asian OEM manufacturing for Custom Touch Screen systems. Spanish or European partners define the specification, perform early prototypes, and handle local liaison, while Chinese factories produce Custom Touch Screen sensors, displays, and assemblies at scale.[1]

Chinese OEMs with ISO and sector‑specific certifications can offer complete Custom Touch Screen assemblies including optical bonding, touch tuning, and functional testing. This “dual‑source” model allows global buyers to secure European‑level application engineering together with competitive high‑volume production for Custom Touch Screen projects.[1]

For a Chinese company in abrasives and refractory materials, this model also makes it easier to integrate reliable Custom Touch Screen interfaces into grinding, cutting, and kilning equipment while controlling overall system cost.[1]

When shortlisting Custom Touch Screen manufacturers and suppliers related to Spain, buyers can follow a structured checklist.[1]

- Confirm the application and environment: indoor retail, outdoor kiosk, on‑vehicle, factory floor, or medical environment, as each drives different Custom Touch Screen requirements.

- Define size, resolution, and brightness: specify minimum nits, viewing angle, and operating temperature for the Custom Touch Screen display.

- Choose touch technology: PCAP for modern multi‑touch HMIs, or resistive/other methods for extreme conditions and legacy systems.

- Review certifications and quality systems: look for ISO‑certified, automotive or industrial‑grade Custom Touch Screen suppliers when projects require higher reliability.

- Evaluate engineering support: firmware tuning, custom drivers, and quick prototyping help optimize Custom Touch Screen performance and reduce debugging time.

Clear communication of drawings, connector types, and EMC constraints at RFQ stage greatly improves the fit of the proposed Custom Touch Screen design.[1]

A well‑organized project with a Custom Touch Screen supplier usually follows a predictable sequence.[1]

1. Requirement collection: mechanical drawings, interface requirements, target environment, regulatory needs, and annual volumes for the Custom Touch Screen.

2. Concept proposal: selection of sensor type, cover glass options, and display parameters, accompanied by a preliminary quotation and schedule.

3. Prototyping: production of Custom Touch Screen samples, verification of optical performance, touch behavior, EMC compatibility, and mechanical fit.

4. Pilot run: small batch to validate assembly, logistics, and field performance under real operating conditions.

5. Mass production and lifecycle management: agreed forecasts, last‑time‑buy options, and redesign planning for long‑running Custom Touch Screen equipment.

This workflow supports both small‑volume special machines and larger rollouts of kiosks or public terminals.[1]

For industrial and public projects in Spain and abroad, design choices can greatly extend the useful life of a Custom Touch Screen system.[1]

- Select industrial‑grade displays rated for extended temperature ranges and high backlight lifetimes suitable for 24/7 Custom Touch Screen operation.

- Use thicker or chemically strengthened cover glass for vandal‑resistant Custom Touch Screen kiosks and public terminals.

- Plan for firmware and driver maintenance, especially when operating systems or mainboards will evolve over the equipment lifetime.

- Consider modular designs so that the Custom Touch Screen assembly can be serviced or replaced without scrapping the whole machine.

Good mechanical sealing and cable strain‑relief also protect the Custom Touch Screen against dust, moisture, and accidental damage.[1]

For machinery in sectors such as abrasives and refractory materials, Custom Touch Screen HMIs can modernize control, improve safety, and enhance data visibility.[1]

- Custom Touch Screen panels unify temperature, pressure, motor load, and recipe settings into a clear graphical interface for operators.

- Rugged Custom Touch Screen HMIs withstand dust, vibration, and elevated ambient temperatures typical of heavy‑industry environments.

- Integration with SCADA or MES allows managers to monitor production KPIs in real time via Custom Touch Screen terminals placed at critical points.

By combining Spanish or European HMI engineering with Chinese OEM manufacturing, such equipment can achieve competitive cost while maintaining strong usability and reliability for Custom Touch Screen interfaces.[1]

Beyond initial delivery, long‑term success of a Custom Touch Screen deployment depends on integration and support strategy.[1]

- OEMs should define spare‑parts policies so that compatible Custom Touch Screen modules remain available throughout the equipment lifecycle.

- Remote diagnostics and logging can help identify issues related to Custom Touch Screen calibration, ghost touches, or ESD events.

- Clear RMA and repair processes with the Custom Touch Screen supplier reduce downtime when units fail in the field.

Aligning firmware versions, interface pinouts, and software images across product families simplifies service and reduces total cost of ownership for Custom Touch Screen systems.[1]

Spain and the wider Iberian region offer a valuable combination of industrial know‑how, application expertise, and EU‑grade quality for Custom Touch Screen projects. Industrial HMI brands, display design houses, and EMS partners collaborate with international PCAP and Custom Touch Screen specialists to deliver solutions covering industrial, transportation, retail, and medical fields.[1]

For global OEMs and system integrators, the most effective strategy is often to combine Spanish or European engineering with cost‑efficient Chinese OEM manufacturing to build long‑lifecycle, high‑reliability Custom Touch Screen systems. By following a clear checklist, defining robust specifications, and selecting partners with proven Custom Touch Screen experience, buyers can reduce project risk and create differentiated equipment for demanding markets.[1]

Professional suppliers aim to keep a Custom Touch Screen design available for many years, especially for industrial and medical equipment. They usually manage component obsolescence via last‑time‑buy notices and compatible replacement versions to protect long‑lifecycle projects.

Before contacting a supplier, prepare the desired size and resolution, brightness, operating temperature, and target application for the Custom Touch Screen. Also define yearly volume, required interfaces, and any special certifications so the supplier can give an accurate proposal.

Yes, a properly tuned Custom Touch Screen can support glove operation and still work reliably in dusty or slightly contaminated environments. This usually requires PCAP controller tuning, suitable cover glass, and an enclosure design that protects the electronics from dust and moisture.

Custom Touch Screen suppliers can print customer logos, use specific glass colors, and design custom borders or cut‑outs to match the final product's industrial design. Many also support custom UI guidelines by coordinating cover glass printing with the on‑screen graphics layout.

Most manufacturers require an MOQ because each Custom Touch Screen design involves tooling, controller tuning, and engineering time. However, some suppliers offer relatively low MOQs for pilot runs, then scale up to higher volumes once the project is validated.

[1](https://www.perplexity.ai/search/3af6e9ed-19bb-49b2-8f9c-8aa458a777dd)

Top Custom Touch Screen Manufacturers and Suppliers in South Korea

Top Custom Touch Screen Manufacturers and Suppliers in Japan

Top Custom Touch Screen Manufacturers and Suppliers in Italy

Top Custom Touch Screen Manufacturers and Suppliers in Portugal

Top Custom Touch Screen Manufacturers and Suppliers in Spain

Top Custom Size Touch Screen Manufacturers and Suppliers in UK

Top Custom Size Touch Screen Manufacturers and Suppliers in Singapore

Top Custom Size Touch Screen Manufacturers and Suppliers in Malaysia