Views: 222 Author: Amanda Publish Time: 2026-01-16 Origin: Site

Content Menu

● Why Australia's market matters

● Leading Australian industrial capacitive touch specialists

>> InTouch Screens (Australia)

>> STX Technology (serving Australia)

>> Other notable suppliers and channels

● Role of global OEM partners such as Reshine Display

● Technical features to evaluate

● Typical cooperation workflow for OEM projects

● Cooperation models with Australian suppliers

● How to select the right partner

● FAQ

>> (1) What are industrial capacitive touch screens?

>> (2) Why choose Australian suppliers for industrial projects?

>> (3) How do global OEMs like Reshine Display work with Australian partners?

>> (4) What specifications matter most when comparing suppliers?

>> (5) How can buyers control cost without sacrificing reliability?

Australia has an active ecosystem of Industrial Capacitive Touch Screen Manufacturers and Suppliers that support mining, transportation, smart manufacturing, healthcare, and public infrastructure projects across the country. For global OEMs and local engineering teams, choosing the right Industrial Capacitive Touch Screens Manufacturers and Suppliers in Australia helps reduce integration risk and ensures long‑term reliability in harsh environments.[1][2][3]

Australia combines strong industrial demand, strict safety standards, and wide‑ranging application scenarios, making it an attractive destination for high‑value Industrial Capacitive Touch Screen Manufacturers and Suppliers. From Perth's mining operations to Sydney's smart buildings and Melbourne's hospitals, end users rely on rugged PCAP HMI solutions for continuous 24/7 operation.[2][3][1]

Demand is driven by automation upgrades in legacy sites and new investments in digital infrastructure, both of which require robust industrial capacitive touch HMIs. As projects scale, buyers increasingly look for Industrial Capacitive Touch Screen Manufacturers and Suppliers that can provide long product lifecycles, clear roadmaps, and stable pricing.[3][4][1]

- Harsh environments such as mining, ports, and food processing demand sealed, IP‑rated, industrial capacitive touch solutions resistant to dust, moisture, and chemicals.[5][1]

- Urban infrastructure projects require vandal‑resistant, sunlight‑readable industrial capacitive touch screens for transport kiosks, ticketing, and wayfinding.[6][2]

- Manufacturing plants and logistics centers increasingly integrate Industrial Capacitive Touch Screen Manufacturers and Suppliers into Industry 4.0 control panels, SCADA interfaces, and panel PCs.[4][7]

Industrial Capacitive Touch Screen Manufacturers and Suppliers in Australia target a broad range of vertical markets that depend on highly reliable HMI interfaces. The same PCAP technology powers small machine‑mount HMIs and large format operator panels on factory floors.[1][2][3][5]

- Mining and resources: Rugged HMIs for drilling rigs, conveyor control, truck loading systems, and processing plants, often with high‑brightness industrial capacitive touch panels for outdoor use.[5][1]

- Transportation: Ticketing kiosks, passenger information displays, depot control systems, and traffic management centers that rely on stable Industrial Capacitive Touch Screen Manufacturers and Suppliers for long lifetimes.[8][2]

- Healthcare and labs: Easy‑to‑clean medical displays and diagnostics terminals with flat‑front PCAP surfaces and chemical‑resistant glass for hygienic operation.[2][4]

- Manufacturing and warehousing: Panel PCs, industrial capacitive touch displays, and HMIs integrated into machines, conveyor systems, packaging lines, and warehouse management terminals.[7][4]

- Smart buildings and retail: Interactive directories, room‑booking panels, and self‑service terminals built on industrial capacitive touch modules designed for continuous operation.[6][2]

Major Industrial Capacitive Touch Screen Manufacturers and Suppliers in Australia include local manufacturers, distributors, and system integrators that provide PCAP monitors, panel PCs, and custom HMI hardware. Many combine imported cores with local engineering, certification, and support services tailored to Australian standards.[3][4][1]

InTouch Screens is a specialist provider of commercial and industrial touch screen monitors and kiosks that extensively uses PCAP technology. Its role as one of the Industrial Capacitive Touch Screen Manufacturers and Suppliers in Australia is supported by in‑house product design, rapid prototyping, and Australian‑made kiosk fabrication.[9][2]

- Offers industrial capacitive touch monitors and kiosks with multi‑touch PCAP glass and edge‑to‑edge toughened surfaces.[2]

- Supports bespoke enclosures, mounting, and integration for industrial, government, and retail projects, making it a flexible choice among Industrial Capacitive Touch Screen Manufacturers and Suppliers.[9][2]

- Operates a local experience hub where customers can review hardware options, discuss user experience, and refine project specifications with in‑house designers.[2]

STX Technology, headquartered in New Zealand, is a leading manufacturer of industrial touch computers and monitors that supplies customers throughout Australia. The company offers a wide portfolio of industrial capacitive touch panel monitors and stainless‑steel displays built for tough conditions.[10][1][5]

- Provides panel‑mount and large‑format industrial capacitive touch displays with IP‑rated front panels and multiple video inputs.[1][5]

- Designs products for demanding sites such as food processing plants and outdoor industrial locations, making STX a strategic partner for Industrial Capacitive Touch Screen Manufacturers and Suppliers focused on rugged HMI projects.[10][1]

- Offers local support for configuration, mounting advice, and integration into existing control systems.[1]

JEA Technologies acts as a specialist distributor and solution provider of projected capacitive touch screens and related peripherals in Australia and New Zealand. The company represents Zytronic, a UK manufacturer known for highly customizable industrial capacitive touch screens and foils.[6]

- Supports custom glass and foil PCAP solutions with options for size, curvature, glass thickness, edge shape, holes, and printed borders.[6]

- By combining Zytronic products with local engineering, JEA strengthens the ecosystem of Industrial Capacitive Touch Screen Manufacturers and Suppliers in Australia and the wider Oceania region.[6]

- Provides consulting and design assistance so OEMs can define the right industrial capacitive touch specifications before committing to tooling.[6]

Australian Touch Systems is an Australian‑owned manufacturer and distributor of touch screen displays based in Melbourne. With decades of experience and partnerships with global brands such as 3M, NEC, and ELO, it participates actively in the Industrial Capacitive Touch Screen Manufacturers and Suppliers space.[11]

- Supplies commercial‑grade and industrial touch displays tailored for kiosks, POS, and industrial HMIs.[11]

- Combines local support with globally recognized components, supporting OEMs that need dependable Industrial Capacitive Touch Screen Manufacturers and Suppliers.[11]

- Offers integration options for different sectors, helping customers match display sizes, touch technologies, and enclosures to project requirements.[11]

Beyond these specialists, multiple distributors and automation suppliers connect buyers to a wide catalog of industrial capacitive touch HMIs and monitors. These organizations often aggregate products from global brands and offer local stock, certification advice, and engineering support.[4][7][3]

- Industrial marketplace platforms in Australia list Industrial Touch Screen Monitor products from brands such as Advantech, Omron, and ICP through local suppliers.[3]

- Automation distributors provide C‑more and other industrial HMI panels with capacitive touch options in different sizes for machine builders and system integrators.[7][4]

- Specialist distributors help engineers compare specifications, prices, and lead times across multiple Industrial Capacitive Touch Screen Manufacturers and Suppliers on a single platform.[3]

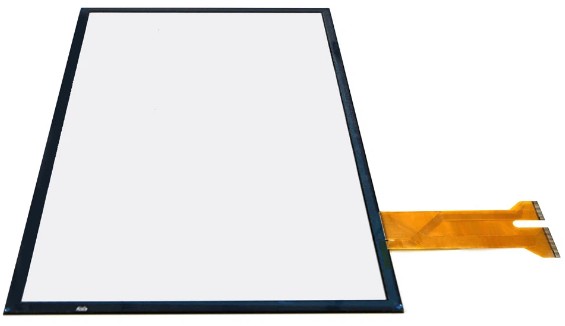

Reshine Display, a professional OEM manufacturer of capacitive and resistive touch screens and TFT LCD displays in China, increasingly cooperates with Industrial Capacitive Touch Screen Manufacturers and Suppliers in Australia. By providing customized industrial PCAP and TFT modules, Reshine Display helps local partners shorten lead times and control costs while maintaining high performance.[12][13][14]

- Reshine Display offers industrial capacitive touch screens from compact 2.4‑inch modules up to large 43‑inch panels, covering handheld terminals, panel PCs, and large HMIs.[13]

- The company specializes in OEM and ODM cooperation, enabling Australian Industrial Capacitive Touch Screen Manufacturers and Suppliers to brand, customize, and integrate modules into finished products.[14][13]

For Australian buyers, this hybrid model is important: local firms deliver mechanical design, compliance, and support, while global OEMs such as Reshine Display supply core industrial capacitive touch and TFT display assemblies. This division of labor allows projects to combine local responsiveness with large‑scale manufacturing and process control.[12][13][14]

When comparing Industrial Capacitive Touch Screen Manufacturers and Suppliers in Australia and abroad, engineering teams should look beyond basic size and resolution. Industrial capacitive touch HMIs must operate reliably for many years with minimal maintenance.[4][5][1][2]

Key evaluation points include:

- Touch technology: Projected capacitive (PCAP) with multi‑touch capability, glove or stylus support, and noise immunity for use near motors and inverters.[2][6]

- Optical performance: Brightness, contrast, anti‑glare or anti‑reflective coatings, and sunlight readability for outdoor or high‑ambient‑light sites.[5][1]

- Mechanical design: Flat‑front glass, bezel styles, stainless‑steel housings, IP‑rating, impact resistance, and mounting options.[8][1]

- Electrical and interfaces: Video inputs (HDMI, DVI, VGA, DisplayPort), USB touch interfaces, and compatibility with industrial panel PCs and PLCs.[4][1]

- Environmental ratings: Operation temperature range, vibration resistance, and sealing against dust and liquids critical for industrial capacitive touch applications.[5][1]

Advanced buyers also evaluate controller firmware features such as palm rejection, moisture handling, and the ability to fine‑tune sensitivity for different front‑glass thicknesses. These parameters influence how Industrial Capacitive Touch Screen Manufacturers and Suppliers can adapt one base design to several end products with varying cover lenses.[13][6]

Industrial projects in Australia often follow a structured workflow when engaging with Industrial Capacitive Touch Screen Manufacturers and Suppliers. A clear process helps reduce redesign cycles and ensures that the final HMI solution matches mechanical, electrical, and UX requirements.[3][4][2]

A common workflow includes:

1. Requirement definition

Engineering teams specify target display size, resolution, brightness, touch performance, mounting method, IP level, interfaces, and certifications.[8][1]

2. Concept and feasibility

Industrial Capacitive Touch Screen Manufacturers and Suppliers review requirements, recommend standard or semi‑custom products, and highlight technical constraints such as glass thickness or maximum cable length.[4][2]

3. Prototype and evaluation

Sample units or prototypes are produced and tested in realistic conditions for EMC behavior, touch accuracy, glove performance, and environmental robustness.[2][6]

4. Design refinement

Based on test feedback, parameters like controller tuning, glass printing, and mechanical tolerances are adjusted in cooperation with global OEMs such as Reshine Display and local partners.[13][6]

5. Pilot run and validation

A pilot batch verifies manufacturing stability and allows final validation at the customer site before volume deployment.[3][4]

6. Mass production and lifecycle management

Industrial Capacitive Touch Screen Manufacturers and Suppliers commit to long‑term availability, last‑time‑buy notifications, and defined processes for handling product changes.[13][1]

Industrial Capacitive Touch Screen Manufacturers and Suppliers in Australia typically engage with OEM and project owners through flexible cooperation models. Choosing the right engagement approach can dramatically impact project risk, cost, and schedule.[4][2][3]

Common models:

- Off‑the‑shelf: Selecting standard industrial capacitive touch monitors or HMIs from local stock for fast deployments and pilot projects.[2][4]

- Semi‑custom: Combining standard PCAP display modules with customized housings, branding, and mounting brackets supplied by local Industrial Capacitive Touch Screen Manufacturers and Suppliers.[6][2]

- Full custom: Co‑developing unique glass cover lenses, sensor patterns, and mechanical designs with global OEMs like Reshine Display and having Australian partners handle certification and on‑site services.[13][6]

For many buyers, semi‑custom solutions deliver the best balance between differentiation and cost, because they reuse established industrial capacitive touch platforms while adjusting mechanical and aesthetic aspects. Full‑custom projects are typically reserved for high‑volume or mission‑critical systems where unique ergonomics or branding justify additional engineering investment.[13][4][2][6]

Selecting among Industrial Capacitive Touch Screen Manufacturers and Suppliers in Australia involves balancing technical requirements, budgets, and project timelines. Engineering teams should focus on long‑term performance rather than only initial unit cost.[3][4][1][2]

Key steps:

- Define environmental and regulatory requirements early, including IP rating, IK impact rating, EMC compliance, and certifications needed in Australia.[8][1]

- Shortlist Industrial Capacitive Touch Screen Manufacturers and Suppliers that can provide technical drawings, long‑term availability guarantees, and clear product lifecycle roadmaps.[4][1]

- Request prototypes or demo units for in‑house testing of touch performance, optical quality, and EMC behavior in real machine environments.[2][6]

- Confirm after‑sales support policies, local repair options, and spare‑part stocking strategies with both Australian partners and upstream OEMs like Reshine Display.[1][13]

Evaluating service quality is as important as checking datasheets, because rapid response to field issues can significantly reduce downtime costs in industrial settings. Buyers should also review references and previous deployments from Industrial Capacitive Touch Screen Manufacturers and Suppliers in similar industries.[3][1][2]

Industrial Capacitive Touch Screen Manufacturers and Suppliers in Australia form an important ecosystem that supports critical industries from mining to healthcare and transportation. By cooperating with global OEM partners such as Reshine Display for core PCAP and TFT modules, Australian firms can deliver tailored, rugged, and cost‑effective HMI solutions that meet local standards and project needs. When selecting Industrial Capacitive Touch Screen Manufacturers and Suppliers, engineering teams should carefully evaluate technical features, environmental ratings, cooperation models, and long‑term support to ensure reliable operation throughout the product lifecycle.[12][13][1][2][3]

Industrial capacitive touch screens use projected capacitive technology with robust glass, sealing, and electronics designed for demanding environments such as factories, mines, and transport hubs. Compared with consumer displays, industrial capacitive touch HMIs offer higher durability, extended temperature ranges, and long‑term availability from specialized Industrial Capacitive Touch Screen Manufacturers and Suppliers.[5][6][1]

Australian Industrial Capacitive Touch Screen Manufacturers and Suppliers understand local standards, harsh climatic conditions, and sector‑specific regulations, which helps reduce engineering risk. Local partners also provide on‑site support, faster logistics, and easier communication compared with relying only on remote overseas vendors.[4][1][2][3]

Global OEMs such as Reshine Display manufacture customized industrial capacitive touch and TFT display modules, which Australian partners then integrate into complete HMIs, kiosks, and enclosures. This cooperation model lets Industrial Capacitive Touch Screen Manufacturers and Suppliers in Australia focus on mechanical design, certification, and service while leveraging large‑scale overseas production.[14][12][13]

When comparing Industrial Capacitive Touch Screen Manufacturers and Suppliers, engineers should prioritize touch performance, optical clarity, IP rating, operating temperature, and product lifecycle support. Interface options, mounting methods, and certifications are equally important to avoid costly redesigns later in the project.[7][1][2][4]

Buyers can manage cost by using semi‑custom solutions that combine standard industrial capacitive touch modules from OEMs like Reshine Display with locally designed housings and mounting systems. Working with experienced Industrial Capacitive Touch Screen Manufacturers and Suppliers in Australia enables optimized designs that focus investment where it most affects reliability and usability.[13][2][3][4]

[1](https://stxtechnology.com.au/industrial-touch-panel-monitors)

[2](https://intouchscreens.com.au)

[3](https://www.industrysearch.com.au/buy/industrial-touch-screen-monitor)

[4](https://www.tekdis.com.au/products/panel-pc-hmi/industrial-monitors.html)

[5](https://stxtechnology.com.au/x7200-large-format-industrial-monitor-range)

[6](https://jeatech.com.au/product/projected-capacitive-touch-screens/)

[7](https://www.directautomation.com.au/operatorpanels/c-more-hmi-devices/hmi-panels.html)

[8](https://www.weidmuller.com.au/en/products/automation_software/touch_panels/index.jsp)

[9](https://intouchscreens.com.au/the-differences-between-capacitive-resistive-industrial-and-ip65-touch-screen-monitors/)

[10](https://stx.co.nz/x7519-19-industrial-touch-panel-monitor)

[11](http://www.touchscreensaustralia.com.au)

[12](https://www.reshine-display.com)

[13](https://www.reshine-display.com/oem-touchscreen.html)

[14](https://www.reshine-display.com/industrial-touchscreen.html)

Top Capacitive Touch Display Manufacturers And Suppliers in Italy

Top Capacitive Touch Display Manufacturers And Suppliers in Spain

Top Capacitive Touch Display Manufacturers And Suppliers in Portugal

Top 7 Inch Hdmi Touch Screen Manufacturers And Suppliers in Vietnam

Top Capacitive Touch Display Manufacturers And Suppliers in Russia

Top Capacitive Touch Display Manufacturers And Suppliers in France

Top Capacitive Touch Display Manufacturers And Suppliers in Saudi Arabia

Top 7 Inch Hdmi Touch Screen Manufacturers And Suppliers in Turkey