Views: 222 Author: Ella Publish Time: 2026-01-18 Origin: Site

Content Menu

● Why Japan Leads in Industrial Capacitive Touch

● Key Industrial Capacitive Touch Players in Japan

>> DMC – Industrial Touchscreen Specialist

>> Tianma Japan – Display and PCAP Integration

>> IDEC – Industrial HMI Touchscreen Panels

>> Automotive and Transportation Capacitive Touch Suppliers

● Technology Trends in Industrial PCAP Touch

● How Reshine Display Supports OEM Projects

● Typical Applications in Japanese Industrial Markets

● Choosing Industrial Capacitive Touch Partners in Japan

● Cooperation Models with Japanese Suppliers

● Sample Comparison of Industrial Capacitive Touch Options

● Extended Insights: Design and Customization Considerations

● Extended Insights: Integration with Industrial Systems

● Extended Insights: Global Sourcing Strategy

● FAQ

>> (1) How do Japanese industrial PCAP touch screens differ from consumer products?

>> (2) Can industrial capacitive touch screens work with gloves and water?

>> (3) What information should OEMs prepare before contacting Japanese suppliers?

>> (4) How do Japanese suppliers handle long‑term availability and EOL?

>> (5) Is it possible to combine Japanese touch modules with overseas assembly partners?

Japan is one of the most advanced and reliable hubs for industrial Capacitive Touch Screen Manufacturers and Suppliers serving automation, transportation, medical, and public information systems. Japanese Capacitive Touch Screen Manufacturers and Suppliers are known for strict quality management, robust long‑term supply, and strong support for demanding OEM and industrial projects.

Japan has a long history in LCD, TFT LCD, and projected capacitive (PCAP) technologies, which form the foundation of modern industrial touch HMI solutions. Many Capacitive Touch Screen Manufacturers and Suppliers in Japan offer integrated modules combining TFT displays with PCAP sensors, controllers, and rugged front glass for harsh environments.

- PCAP technology senses changes in capacitance through transparent electrodes, enabling precise, multi‑touch input.

- Industrial Capacitive Touch Screen Manufacturers and Suppliers in Japan tune controllers and firmware so that panels can be used with gloves, moisture, and electrical noise on factory floors.

- Japanese partners typically provide extended product lifecycles, which is critical for medical, transportation, and industrial automation equipment.

For global OEMs, working with Japanese Capacitive Touch Screen Manufacturers and Suppliers means predictable quality, detailed documentation, and stable supply backed by strong engineering support.

Japan hosts a mix of specialized industrial touch manufacturers, HMI solution suppliers, and display makers that integrate PCAP sensors. Below are some representative types of Capacitive Touch Screen Manufacturers and Suppliers active in the Japanese and global markets.

DMC is a specialized touchscreen manufacturer providing HMI components and systems for business, industrial, and IoT sectors. Its portfolio includes capacitive touch panels, resistive panels, and integrated panel computers and monitors tailored for factory and logistics applications.

- DMC's capacitive touch panels emphasize high responsiveness, optical clarity, and durability for industrial equipment and public terminals.

- As part of a larger industrial group, DMC can support Capacitive Touch Screen Manufacturers and Suppliers globally with design, production, and after‑sales service.

DMC typically works closely with OEM engineers on cover glass design, surface treatment, and mechanical integration, making it an attractive partner for customized industrial HMI systems.

Tianma Japan focuses on LCDs for industrial and professional applications and provides projected capacitive touch panels as factory‑installed options. It offers one‑stop PCAP solutions with integrated touch sensors, controllers, drivers, and tuning tools for OEM customers.

- Tianma Japan supplies industrial TFT LCD modules with matching PCAP sensors in a wide range of sizes for indoor and outdoor use.

- The company delivers factory‑tuned PCAP modules, including firmware and special tuning software, simplifying adoption for Capacitive Touch Screen Manufacturers and Suppliers and system integrators.

For OEMs, sourcing from Tianma Japan allows simultaneous optimization of viewing performance, touch responsiveness, and environmental robustness within a single LCD‑PCAP module.

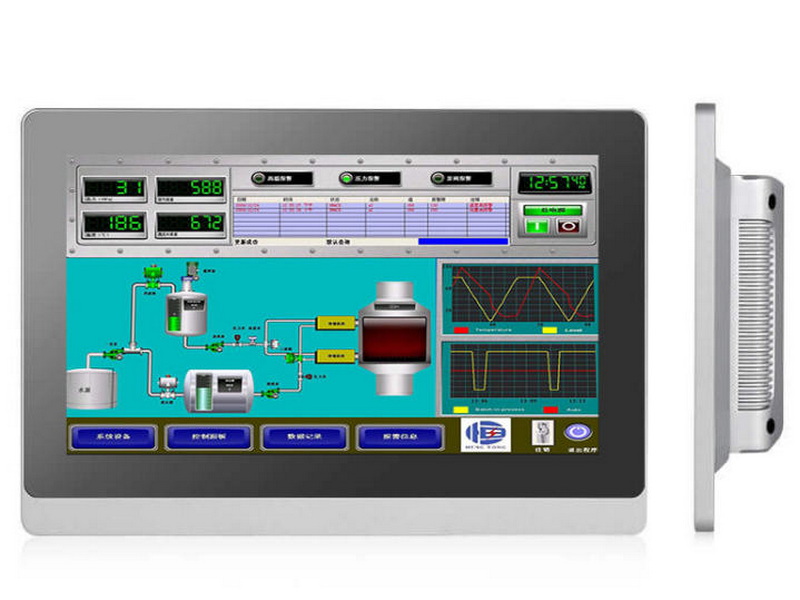

IDEC is well known for operator interfaces and industrial HMI touchscreens used in automation, machinery, and building systems. Its HG‑series panels integrate TFT LCDs with PCAP front glass, combining high visibility with rugged construction.

- IDEC's PCAP HMIs support multi‑touch, high brightness, wide temperature range, and strong protection for harsh environments.

- The lineup spans sizes from compact 4.3‑inch to large 15‑inch screens, covering small machines up to large‑scale systems with Ethernet, serial, and expansion I/O.

Because IDEC focuses on complete HMI units, many Capacitive Touch Screen Manufacturers and Suppliers regard these products as reference designs for industrial panel integration and control applications.

Japan is also strong in automotive and in‑vehicle touch panels, which often share technology with industrial PCAP solutions. Automotive suppliers provide capacitive touch panels and overlays designed for dashboards, center consoles, and in‑vehicle displays.

- Some automotive touch suppliers began mass production of capacitive touch panels early and now have many years of field experience.

- Their expertise in vibration, temperature, and EMI control translates well to industrial Capacitive Touch Screen Manufacturers and Suppliers serving transportation, construction machinery, and rail.

For global OEMs, collaborating with such suppliers can bring automotive‑grade reliability and safety standards into industrial HMI platforms.

Industrial Capacitive Touch Screen Manufacturers and Suppliers in Japan use projected capacitive technology as the mainstream solution for new HMI designs. Continuous improvements in controllers, firmware, and sensor patterns have addressed many early limitations of PCAP in harsh environments.

- Advanced algorithms now allow PCAP touchscreens to operate with thick work gloves and in the presence of moisture, oils, and electrical noise.

- Thicker cover glass improves scratch resistance and durability while maintaining precise touch detection thanks to optimized signal processing.

- Integrated PCAP‑TFT modules reduce EMI issues and simplify mechanical design compared with separate touch and display components.

These trends help Capacitive Touch Screen Manufacturers and Suppliers deliver robust industrial touch solutions for factories, outdoor kiosks, marine systems, and medical devices.

As a dedicated factory producing standard and custom touchscreens and TFT LCD displays, Reshine Display provides OEM services to global brands, wholesalers, and manufacturers. While Japanese Capacitive Touch Screen Manufacturers and Suppliers offer local engineering and application expertise, many overseas buyers also work with international partners like Reshine Display for flexible customization and competitive cost.

- Reshine Display focuses on industrial and commercial TFT LCD modules with integrated capacitive touch, suitable for automation, medical, smart home, and transportation terminals.

- OEM customers can request custom cover glass, silk printing, interface options, and bonding structures to match their enclosures and system requirements.

By combining modules from Japanese and Chinese Capacitive Touch Screen Manufacturers and Suppliers, global OEMs can balance performance, localization, and cost in large‑scale deployment projects.

Industrial Capacitive Touch Screen Manufacturers and Suppliers in Japan target a broad range of application sectors that require reliable, long‑lifecycle HMI solutions. PCAP‑based touch products are increasingly chosen instead of resistive panels due to better optical and mechanical performance.

- Factory automation: PLC operator panels, machine tools, robotics cells, and production monitoring systems use PCAP HMIs with high brightness and wide temperature ranges.

- Transportation: Railway control consoles, marine systems, in‑vehicle terminals, and ticketing kiosks adopt rugged capacitive touch screens with high vibration and EMC resistance.

- Medical and laboratory: Displays and Capacitive Touch Screen Manufacturers and Suppliers support easy cleaning, chemical resistance, and precise control in diagnostic and imaging equipment.

- Public information and retail: Ticket machines, vending, POS terminals, and digital signage integrate vandal‑resistant front glass and sunlight‑readable displays.

These sectors often demand long product lifecycles, which Japanese suppliers can support through stable supply and backward‑compatible designs.

When selecting industrial Capacitive Touch Screen Manufacturers and Suppliers in Japan, overseas OEMs should evaluate not only pricing but also technical fit, lifecycle, and support capabilities. Japanese partners are generally responsive to detailed engineering cooperation, but clear communication of requirements is essential.

- Performance and environment

- Check operating temperature, brightness, viewing angles, and protection ratings against application needs such as outdoor or wash‑down environments.

- Confirm glove operation, water rejection, and immunity to electrical noise for factory and field applications.

- Mechanical and optical design

- Review cover glass thickness, surface treatments such as anti‑glare or anti‑reflection, and bezel or frameless options.

- Validate optical bonding quality between PCAP sensor and display to minimize reflections and improve sunlight readability.

- Lifecycle and logistics

- Ask about product roadmap, end‑of‑life policy, and second‑source options for critical industrial or medical systems.

- Evaluate lead times, minimum order quantities, and global logistics support, especially if combining Japanese modules with overseas assembly or integration.

By systematically checking these items, buyers can identify the most suitable Capacitive Touch Screen Manufacturers and Suppliers for long‑term cooperation in Japan.

Global OEMs can work with Japanese industrial Capacitive Touch Screen Manufacturers and Suppliers through different cooperation models depending on scale and technical complexity.

- Direct sourcing of PCAP‑TFT modules

- OEMs purchase standard or semi‑custom integrated modules with specified interfaces and mechanical dimensions.

- This model suits mid‑ to high‑volume projects with defined mechanical designs and firmware resources.

- Joint development of fully customized HMI

- The supplier co‑designs sensor patterns, cover glass, mechanical housing, and firmware tuning for specific applications such as medical diagnostics or heavy machinery.

- This approach is typical for high‑value equipment where unique ergonomics and branding are important.

- Cooperation via system integrators and OEM partners

- Some Japanese Capacitive Touch Screen Manufacturers and Suppliers work through local or regional integrators that bundle touch modules with CPUs, operating systems, and enclosure design.

- Overseas customers may also pair Japanese modules with integration support from companies like Reshine Display or other global partners.

Choosing the right cooperation model ensures that technical risks, costs, and time‑to‑market remain balanced throughout the project lifecycle.

Below is an example of how different types of industrial Capacitive Touch Screen Manufacturers and Suppliers can be positioned for OEM decision‑making.

Supplier / Type | Main strength | Typical size range | Key applications | Notable features |

DMC (Japan) | Specialized industrial HMI touch panels | Small to medium industrial panels | Factory automation, logistics, kiosks | High responsiveness, industrial customization |

Tianma Japan (Japan) | Integrated PCAP-TFT display modules | Wide range industrial LCD sizes | Medical, industrial, outdoor terminals | One-stop PCAP modules with tuning tools |

IDEC (Japan) | Complete HMI panel products | 4.3–15 inch operator interfaces | Machines, building automation, systems | Strong protection, multi-protocol, wide temperature range |

Automotive touch suppliers (Japan) | Automotive-grade PCAP panels | In-vehicle display formats | Vehicles, transport, heavy equipment | Vibration and EMC robustness, safety standards |

Reshine Display (Global OEM partner) | Custom PCAP-TFT modules for OEMs | From compact to large industrial displays | Industrial, smart home, medical, kiosks | Flexible customization and OEM-focused service |

This type of comparison helps buyers map requirements against the capabilities of different Capacitive Touch Screen Manufacturers and Suppliers when planning new projects.

Beyond choosing a supplier, OEMs should understand key design decisions that influence performance, usability, and long‑term reliability of industrial PCAP solutions. These aspects are where collaboration between Capacitive Touch Screen Manufacturers and Suppliers and OEM engineers becomes especially important.

- Cover glass thickness and material

- Thicker glass improves impact resistance and vandal resistance, which is important for public kiosks and industrial machines exposed to tools.

- Chemically strengthened glass or added surface coatings can further enhance durability and cleaning resistance.

- Surface treatments and optics

- Anti‑glare and anti‑reflection coatings reduce reflections from ambient lighting, improving readability under bright factory lighting or sunlight.

- High‑transmission substrates and good optical bonding maintain contrast and color fidelity even with additional protective layers.

- Controller tuning and firmware

- Proper tuning ensures stable operation near motors, inverters, and RF sources common in industrial environments.

- Specialized firmware profiles can be created for different glove materials, stylus types, or water‑rich environments such as food processing or outdoor terminals.

If these details are finalized early and communicated clearly, Capacitive Touch Screen Manufacturers and Suppliers in Japan and their global partners can deliver better‑matched modules and shorten the trial‑and‑error cycle.

Industrial PCAP modules must integrate with controllers, communication networks, and mechanical enclosures, which adds additional criteria to supplier selection.

- Electrical interfaces

- Common video interfaces include RGB, LVDS, and increasingly MIPI or eDP for higher resolutions.

- Touch interfaces may use I⊃2;C, USB, or SPI; selecting a controller that aligns with the main CPU simplifies software integration.

- EMC and grounding

- Proper shielding, grounding of the cover glass, and cable routing are vital for stable capacitive touch performance.

- Capacitive Touch Screen Manufacturers and Suppliers often provide layout guidance and reference designs to help OEMs meet EMC targets.

- Enclosure and sealing

- Industrial and outdoor applications often require IP65 or higher front‑panel protection, which affects gasket design and mounting methods.

- Bezel‑less or flat‑front designs are popular for hygienic environments, requiring careful bonding of the PCAP module to the housing.

Working with experienced Capacitive Touch Screen Manufacturers and Suppliers ensures that these system‑level considerations are addressed early instead of becoming late design issues.

Many OEMs now combine Japanese technology with manufacturing and customization from other regions to achieve optimal cost and flexibility.

- Dual‑sourcing strategy

- Critical products may use a Japanese primary module and a second source from another region with similar specifications.

- This strategy reduces supply risk while maintaining high performance and quality.

- Regional customization

- Local partners can adapt PCAP‑TFT modules with region‑specific enclosures, certifications, or user‑interface languages.

- This approach helps brands serve different markets while still relying on core modules from leading Capacitive Touch Screen Manufacturers and Suppliers.

- Lifecycle management and upgrades

- Over the life of a product, display resolutions, aspect ratios, or interface standards may change.

- Long‑term partners can provide compatible next‑generation modules, simplifying upgrade paths for installed equipment.

A clear global sourcing strategy enables OEMs to use the strengths of Japanese suppliers while leveraging worldwide networks for cost‑effective integration and deployment.

Industrial Capacitive Touch Screen Manufacturers and Suppliers in Japan combine advanced PCAP technology, robust TFT LCD integration, and strict quality standards, making them highly attractive partners for demanding OEM projects. By understanding the strengths of specialized touchscreen makers, integrated display suppliers, and HMI system brands, overseas buyers can select the right Japanese partners while also cooperating with global factories such as Reshine Display for flexible customization and cost optimization.

Contact us to get more informations!

Japanese industrial PCAP modules are designed for wide temperature ranges, longer lifecycles, and stable supply, unlike many consumer‑grade touchscreens used in smartphones and tablets. Capacitive Touch Screen Manufacturers and Suppliers in Japan also support higher brightness, rugged cover glass, and glove operation for factory and outdoor use.

Modern industrial PCAP panels incorporate advanced controller firmware and thicker glass to detect inputs through various work gloves and reject false touches from water. Many Capacitive Touch Screen Manufacturers and Suppliers offer tuning services to match sensitivity, palm rejection, and noise immunity to the customer's specific environment.

OEMs should prepare target display size, resolution, brightness, operating temperature, interface type, and mechanical constraints, plus any certification requirements. This allows Capacitive Touch Screen Manufacturers and Suppliers in Japan to quickly propose standard or semi‑custom modules, project cost estimates, and development schedules.

Industrial‑focused Japanese Capacitive Touch Screen Manufacturers and Suppliers usually publish product lifecycle policies and provide advance end‑of‑life notices. They often maintain compatible replacement modules or long‑term production plans, which is essential for medical, transportation, and industrial equipment that must remain in service for many years.

Yes, many OEMs source key PCAP‑TFT modules from Japanese suppliers while using overseas factories or partners such as Reshine Display for final assembly, enclosure design, or localization. This hybrid strategy leverages Japanese technology and quality while taking advantage of global Capacitive Touch Screen Manufacturers and Suppliers for cost‑effective integration and regional support.

1. https://www.dush.co.jp/english/

2. https://www.dush.co.jp/english/product/touchscreen/

3. https://www.tianma.co.jp/en/technology/technology_trend_4.html

4. https://mktg.idec.com/en-gb/operator-interfaces/hmi-screens

5. https://us.idec.com/idec-us/en/USD/Operator-Interfaces/HMI/c/HMI

6. https://www.reshine-display.com

7. https://www.reshine-display.com/industrial-touchscreen.html

8. https://www.reshine-display.com/top-custom-touch-screen-display-manufacturers-and-suppliers-in-japan.html

Top Capacitive Touch Display Manufacturers And Suppliers in Italy

Top Capacitive Touch Display Manufacturers And Suppliers in Spain

Top Capacitive Touch Display Manufacturers And Suppliers in Portugal

Top 7 Inch Hdmi Touch Screen Manufacturers And Suppliers in Vietnam

Top Capacitive Touch Display Manufacturers And Suppliers in Russia

Top Capacitive Touch Display Manufacturers And Suppliers in France

Top Capacitive Touch Display Manufacturers And Suppliers in Saudi Arabia

Top 7 Inch Hdmi Touch Screen Manufacturers And Suppliers in Turkey