Views: 222 Author: Amanda Publish Time: 2026-01-11 Origin: Site

Content Menu

● Why Japan Leads in TFT Touch Screen Technology

● Key Application Markets for TFT Touch Screens in Japan

● Representative TFT Touch Screen Manufacturers and Suppliers in Japan

● Other Important Japanese Participants

● How Global OEMs Typically Source from Japan

● Why Work with Specialized TFT Touch Screen Manufacturers and Suppliers

● Role of Reshine Display as an OEM Partner

● Content and Marketing Strategy for TFT Touch Screen Pages

● How to Evaluate TFT Touch Screen Manufacturers and Suppliers in Japan

● Working with Japanese and Overseas Partners Together

● FAQ

>> 1. What are the advantages of sourcing from TFT Touch Screen Manufacturers and Suppliers in Japan?

>> 2. How do Japanese TFT Touch Screen Manufacturers and Suppliers support industrial projects?

>> 3. Can overseas OEMs work with both Japanese brands and non‑Japanese TFT touch partners?

>> 4. What should be checked when choosing TFT Touch Screen Manufacturers and Suppliers?

>> 5. How does an OEM factory like Reshine Display cooperate with Japanese‑focused projects?

Japan is one of the most important global hubs for advanced TFT Touch Screen technology, especially for industrial, automotive, and professional-grade applications. For OEMs, traders, and solution providers, understanding the ecosystem of TFT Touch Screen Manufacturers and Suppliers in Japan is essential to building reliable, long‑term projects that can compete in demanding global markets.[1][2]

Japan's display industry is large and still growing, with the Japan display market estimated at around USD 10.2 billion in 2024 and expected to reach USD 14.3 billion by 2033, driven by high‑quality displays for automotive, healthcare, and industrial equipment. Within this ecosystem, TFT Touch Screen Manufacturers and Suppliers focus on reliability, long lifecycle support, and strict quality control that appeal strongly to global OEM customers.[2][1]

- Strong R&D and engineering culture for precision displays and touch interfaces in both consumer and industrial sectors.[1]

- Government and corporate investment in next‑generation display technologies such as LCD, OLED, and Micro‑LED that work alongside TFT touch solutions.[3]

- Established global brands (Sharp, Japan Display, Kyocera, Panasonic, etc.) coexisting with specialty TFT Touch Screen Manufacturers and Suppliers focused on niche industrial segments.[4][5]

Japan's long tradition of precision manufacturing also shapes the way TFT touch screens are designed, produced, and qualified, with strict internal testing and customer‑specific validation processes. This culture of quality makes Japanese TFT Touch Screen Manufacturers and Suppliers attractive partners for sectors like automotive, medical, and transportation where field failures are extremely costly.[6][4]

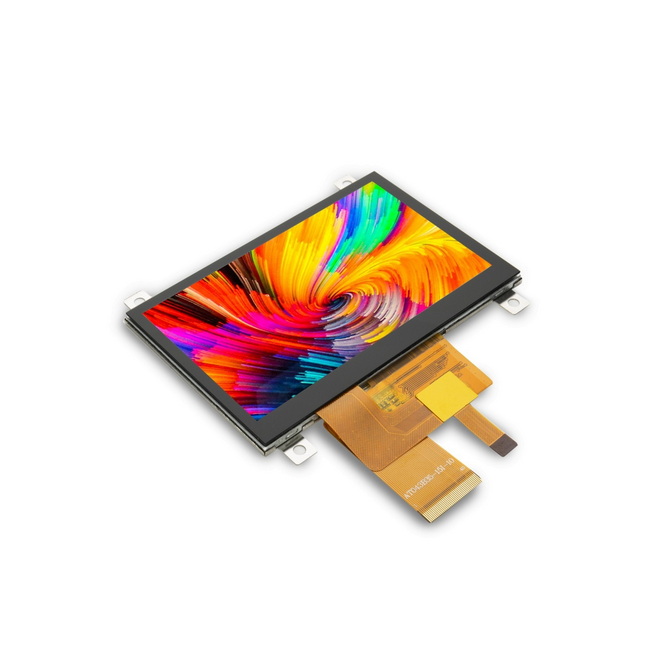

The main demand drivers for TFT Touch Screen Manufacturers and Suppliers in Japan include automotive HMI, factory automation, medical devices, transportation, kiosks, and smart infrastructure projects. As 5G, IoT, and AI applications expand, Japanese end users expect higher‑resolution, sunlight‑readable, and durable TFT touch screens for both outdoor and indoor use, often operated with gloves or in wet conditions.[3][1]

Typical application clusters include:

- Automotive clusters, center‑stack displays, rear‑seat entertainment, and EV charging stations.

- Industrial HMIs, PLC operator panels, clean‑room terminals, and test equipment interfaces.

- Medical monitors, diagnostic instruments, patient terminals, and handheld analyzers.

- Ticketing terminals, POS, ATMs, and public information kiosks in stations, malls, and airports.

In many of these segments, TFT Touch Screen Manufacturers and Suppliers must meet strict long‑term supply requirements, often maintaining compatible modules over many years to match equipment lifecycles. As a result, product change control and end‑of‑life management are critical capabilities for any serious supplier to the Japanese market.[7][4]

Japan hosts a mix of original display manufacturers, touch panel specialists, and solution integrators that together shape the market for TFT Touch Screen Manufacturers and Suppliers. Below are some representative players that overseas buyers frequently encounter when sourcing from Japan or from partners who use Japanese technology.[4][7]

Japan Display Inc. is a major Japanese manufacturer of small to medium‑size LCDs, widely used in smartphones, tablets, automotive clusters, and industrial devices. JDI leverages advanced TFT processes, high pixel density, and low‑power driving technologies, making it an important upstream partner for many TFT Touch Screen Manufacturers and Suppliers who integrate their panels into complete touch modules.[8][4]

As an upstream panel source, JDI typically works with module assemblers and OEMs who add touch sensors, cover glass, and mechanical frames. This makes JDI‑based solutions attractive for projects that require compact size, high resolution, and excellent viewing characteristics in automotive and portable devices.[8][4]

Sharp is one of Japan's historic leaders in LCD and TFT technology and remains a critical reference among TFT Touch Screen Manufacturers and Suppliers worldwide. Sharp's high‑resolution, wide‑color‑gamut, and low‑power displays are used in consumer electronics, industrial instruments, automotive devices, and signage, often combined with projected capacitive or resistive touch solutions by external module specialists.[5][4]

Sharp's display innovations, including advanced backlight and power‑saving technologies, have helped shape modern expectations for thin, bright, and energy‑efficient TFT touch screens. This reputation means that TFT Touch Screen Manufacturers and Suppliers who integrate Sharp panels can often promote strong performance credentials to global OEM customers.[5][4]

Kyocera operates a dedicated display and touch panel business, producing robust LCDs and touch panels for industrial, automotive, and medical markets. As a well‑known Japanese supplier of LCDs and touch panels, Kyocera works closely with TFT Touch Screen Manufacturers and Suppliers who need high‑reliability modules that can withstand vibration, temperature extremes, and continuous operation.[6][4]

Kyocera's experience in ceramic materials and packaging adds value in environments where mechanical stress, moisture, or shock would damage less robust products. For this reason, Kyocera‑based TFT touch modules are often specified for outdoor terminals, transport systems, and mission‑critical industrial controls.[4][6]

DMC is a Japanese company focused on touchscreens and HMI solutions, including panel computers, monitors, and industrial displays for business and IoT sectors. The company's portfolio targets industrial automation, logistics, and smart‑infrastructure customers, making it a relevant brand in the network of TFT Touch Screen Manufacturers and Suppliers servicing factories, warehouses, and control rooms.[9]

By combining touch technology, controller electronics, and housing designs, DMC delivers more complete HMI solutions than basic component providers. This model is attractive to system integrators and OEMs that prefer to buy pre‑engineered touch terminals instead of designing from scratch.[7][9]

In addition to these brands, multiple other display and touch‑related companies contribute to the ecosystem of TFT Touch Screen Manufacturers and Suppliers in Japan. These companies operate at different levels of the value chain, from core panel manufacturing to distribution and system integration.[7][4]

- Panasonic: Professional and industrial‑grade LCD display solutions used in medical, broadcast, and industrial systems.[5][4]

- NEC Display Solutions: High‑end LCD displays for broadcasting, corporate, and control‑room applications where color and reliability are critical.[4]

- Ortustech: A Japanese specialist in small, high‑performance TFT LCDs, often used in portable and industrial devices requiring fine detail and strong readability.[4]

- Various industrial touchscreen and panel monitor makers and distributors listed in Japanese technical directories, serving diverse application niches.[10][7]

Together, these companies give OEMs many options for combining panel technology, touch solutions, and mechanical integration under a unified purchasing strategy. For global buyers, understanding which companies focus on which layers of the stack is essential when evaluating TFT Touch Screen Manufacturers and Suppliers for a new project.[11][4]

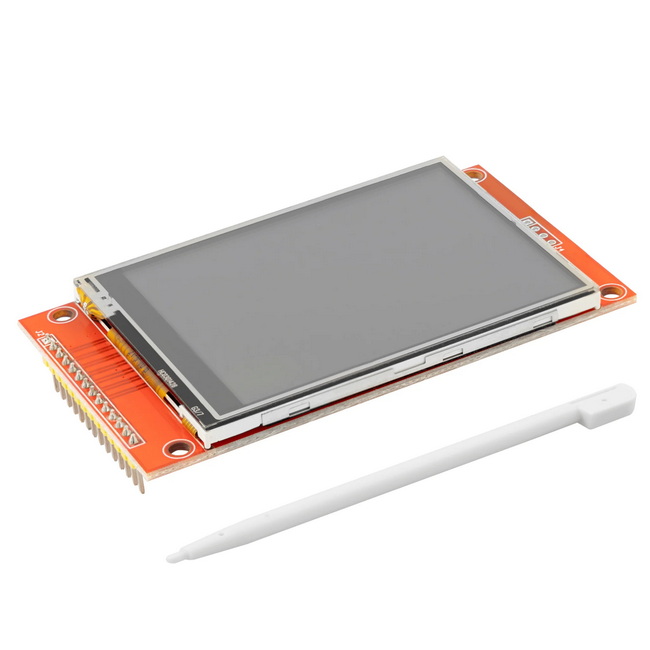

Many overseas buyers do not purchase directly from core Japanese panel makers but instead work with TFT Touch Screen Manufacturers and Suppliers that integrate Japanese TFT cells with touch sensors, cover glass, and custom interfaces. This model allows OEM customers to get a finished, plug‑and‑play TFT touch module tailored to their mechanical design, interface, and certification needs while benefiting from Japanese display quality.[12][13][7][4]

A typical sourcing chain looks like this:

- Panel manufacturers provide TFT LCD cells and sometimes basic display modules.

- TFT Touch Screen Manufacturers and Suppliers add projected‑capacitive or resistive touch layers, optical bonding, and custom cover glass.

- Distributors and integrators in Japan and abroad provide local engineering, stocking, and after‑sales support to OEMs and system integrators.

This layered sourcing model also helps manage risk and flexibility, because TFT Touch Screen Manufacturers and Suppliers can redesign modules around alternative panels when certain models are discontinued or capacity is constrained. For global customers, it means there are more options for cost, lead time, and specification balancing while still retaining access to Japanese core technology.[12][4]

For global OEM and ODM projects, specialized TFT Touch Screen Manufacturers and Suppliers can bridge the gap between Japanese display technology and customer‑specific requirements. These companies often combine displays from Japan, Taiwan, Korea, and China, offering flexible sourcing, engineering, and cost structures while still aligning with Japanese reliability expectations.[13][11][12][4]

Key advantages include:

- Single point of contact for display, touch, interface, firmware, and mechanical customization.

- Long‑term supply planning, EOL management, and alternative panel proposals when products are discontinued.

- Faster prototyping cycles thanks to ready‑to‑use TFT touch platforms and reference designs.

Specialized TFT Touch Screen Manufacturers and Suppliers also handle practical integration details, such as cable routing, EMI control, mechanical mounting, and environmental sealing. Taking care of these details offloads risk from OEM engineers and shortens project schedules.[11][13]

Reshine Display is a factory specializing in standardized and customized touch screens and TFT LCD displays, providing OEM services to global brands, wholesalers, and manufacturers. For buyers focusing on Japanese and Asia‑Pacific projects, a partner like Reshine Display can design TFT touch screen solutions that align with Japanese application standards while leveraging flexible OEM manufacturing resources.

Reshine Display can cooperate with the broader network of TFT Touch Screen Manufacturers and Suppliers by:

- Selecting suitable TFT cells (including Japanese and other Asian sources) to match customer brightness, resolution, and size targets.

- Designing custom projected‑capacitive or resistive touch layers, including cover glass printing, logo placement, and protective coatings.

- Providing full OEM services such as cable and connector optimization, driver integration, reliability testing, and logistics support for global shipments.

By combining deep manufacturing experience with an understanding of international application requirements, Reshine Display positions itself as a practical OEM partner for companies that want to benefit from the expertise of TFT Touch Screen Manufacturers and Suppliers without running their own factories.[11]

From a marketing and SEO perspective, companies promoting TFT Touch Screen Manufacturers and Suppliers in Japan should build informative, technically detailed pages that answer buyer questions and demonstrate application know‑how. High‑value content improves search visibility while also supporting sales teams and distributors in discussions with engineers and purchasing managers.[7][11]

Effective content elements include:

- Clear explanations of display and touch technologies, including viewing angle, brightness, and controller interfaces.

- Application‑oriented sections for automotive, medical, industrial, and retail, showing how different TFT touch solutions are configured.

- Case‑study style descriptions of successful projects, even when anonymized, to show how TFT Touch Screen Manufacturers and Suppliers solve real‑world problems.

In addition, webmasters can enrich these pages with multimedia such as product demonstrations, assembly process showcases, and application simulations, further improving engagement and time on page. This content strategy helps position a supplier not just as a component vendor but as a solution partner for long‑term collaboration.[11][4]

When shortlisting TFT Touch Screen Manufacturers and Suppliers from Japan or partners serving the Japanese market, international buyers should evaluate several technical and commercial factors. Comprehensive evaluation reduces project risk and helps ensure that the chosen supplier can support the full product lifecycle.[7][11]

Key evaluation points:

- Display technology and specification range: sizes, resolutions, brightness, viewing angles, and wide‑temperature options suitable for the target environment.[12]

- Touch technology expertise: projected capacitive, resistive, multi‑touch capability, glove or water operation robustness, and controller options.[9][6]

- Industrial reliability: lifetime, backlight durability, vibration resistance, and component derating for harsh environments such as vehicles and outdoor terminals.[6]

- Engineering support: interface options (LVDS, eDP, MIPI, RGB, SPI), firmware support, color tuning, and availability of design tools.

- Quality systems and certifications: IATF, ISO, and sector‑specific approvals for automotive, medical, or railway use where required.[13][4]

Commercial and logistics aspects are just as important as technology. Buyers should confirm sample lead times, production lead times, minimum order quantities, stocking strategies, and after‑sales support for returns or field issues. Strong communication and transparent documentation practices are hallmarks of professional TFT Touch Screen Manufacturers and Suppliers.[11][7]

In many global projects, final products combine Japanese design standards and performance expectations with flexible manufacturing partners that understand TFT Touch Screen Manufacturers and Suppliers worldwide. A hybrid sourcing strategy may use Japanese panels for critical models while relying on non‑Japanese TFT touch modules for cost‑sensitive SKUs that still meet project requirements.[2][1][4][11]

This cooperative structure often follows a pattern:

- Early concept discussions define which assemblies must rely on Japanese panel technology and which can be served by alternative sources.

- Co‑design between Japanese technology providers, specialized TFT Touch Screen Manufacturers and Suppliers, and OEM factories ensures alignment on electrical, optical, and mechanical targets.

- Long‑term framework agreements manage pricing, volume ramp‑up, and product change notifications to protect production continuity.

Such hybrid cooperation allows brands to position their premium lines on top‑tier Japanese technology while using well‑engineered, cost‑effective modules on mid‑range or entry‑level products. For a supplier like Reshine Display, this environment creates opportunities to serve global customers as an OEM bridge between Japanese innovation and international manufacturing flexibility.[4]

Japan remains a premier center for display innovation, and its ecosystem of TFT Touch Screen Manufacturers and Suppliers continues to influence global standards for reliability and performance. By understanding key Japanese players such as Japan Display, Sharp, Kyocera, and DMC, and by cooperating with specialized OEM partners capable of delivering complete TFT touch modules, global buyers can create robust, competitive products for industrial, automotive, and commercial markets. A strategic combination of Japanese display technology, expert TFT Touch Screen Manufacturers and Suppliers, and experienced OEM factories like Reshine Display gives brands a strong platform for long‑term success in demanding applications and international projects.[1][8][9][6][4]

Japanese TFT Touch Screen Manufacturers and Suppliers are known for high reliability, strict quality control, and long product lifecycles in industrial and automotive applications. They also benefit from a mature ecosystem of component suppliers and R&D resources, which supports advanced features such as high brightness, wide temperature range, and precise touch performance.[2][1][6][4]

TFT Touch Screen Manufacturers and Suppliers serving Japan's industrial market typically offer extended temperature ranges, ruggedized designs, and long‑term availability suitable for factory automation and infrastructure projects. Many also provide engineering services such as interface customization, optical bonding, and environmental sealing, helping OEMs integrate displays quickly into industrial equipment.[9][13][6][7]

Many overseas OEMs combine Japanese core display technologies with TFT Touch Screen Manufacturers and Suppliers located in other regions to achieve a balance of cost and performance. This allows them to keep critical models on Japanese panels while using more cost‑optimized TFT touch modules for other product tiers, without sacrificing reliability where it matters most.[1][2][4][11]

Buyers should review display specifications, touch performance, environmental robustness, interface options, and relevant quality certifications when evaluating TFT Touch Screen Manufacturers and Suppliers. It is also important to confirm support for long‑term supply, clear communication on product changes, and available design resources such as drawings, 3D models, and firmware support.[13][12][7][11]

An OEM factory specializing in touch screens and TFT LCD modules can tailor custom TFT touch assemblies that align with the design expectations of Japanese and global projects. Such a partner can integrate suitable panels, design cover glass and touch sensors, and manage production, testing, and logistics for international customers working alongside Japanese TFT Touch Screen Manufacturers and Suppliers.[4][11]

[1](https://www.imarcgroup.com/japan-display-market)

[2](https://www.futuremarketinsights.com/reports/japan-displays-market)

[3](https://www.linkedin.com/pulse/japan-micro-led-display-market-size-2025-ai-technology-eus7f)

[4](https://eagle-touch.net/a-comprehensive-overview-of-top-global-tft-lcd-manufacturers/)

[5](https://auroralcd.com/top-10-lcd-display-companies-in-japan/)

[6](https://global.kyocera.com/prdct/display/)

[7](https://www.globalspec.com/local/2238/C_JP)

[8](https://www.j-display.com/en/)

[9](https://www.dush.co.jp/english/)

[10](https://www.ipros.com/en/cg3/Touch%20panel%20monitor/)

[11](https://us.metoree.com/categories/touch-panel/)

[12](https://www.data-modul.com/en/products/product-finder/find-your-tft-display)

[13](https://www.shinden.co.jp/english/products/category/lcd.html)