Views: 222 Author: Wendy Publish Time: 2025-12-08 Origin: Site

Content Menu

● Why China Leads in TFT Touch Screen Manufacturing

● Top 10 TFT Touch Screen Manufacturers in China

>> 2. TCL CSOT (China Star Optoelectronics)

>> 4. InfoVision Optoelectronics (IVO)

>> 5. AV‑Display (Shenzhen AV‑Display Co., Ltd.)

>> 6. Kingtech Group Co., Ltd.

>> 7. Sunul Electronic Co., Ltd.

>> 8. DWIN Technology Co., Ltd.

>> 9. Ruixiang Touch Display Technology Co., Ltd.

>> 10. ChengHao Optoelectronic Co., Ltd.

● Main Application Fields of TFT Touch Screen Solutions

● Capacitive vs. Resistive TFT Touch Screen

>> Capacitive TFT Touch Screen

● Key Performance Parameters of TFT Touch Screen Modules

● How to Select a TFT Touch Screen Manufacturer in China

● Customization Options for TFT Touch Screen Projects

● Typical TFT Touch Screen Project Flow with a Chinese Supplier

>> 5. Pilot run and mass production

● Example Media Ideas: Images and Videos to Use

● How Abrasives and Refractories Relate to TFT Touch Screen Hardware

● FAQ About TFT Touch Screen Manufacturers in China

>> (1) What factors matter most when choosing a Chinese TFT Touch Screen supplier?

>> (2) Can Chinese manufacturers support fully customized TFT Touch Screen designs?

>> (3) How do lead times usually look for TFT Touch Screen orders?

>> (4) How do Chinese suppliers ensure TFT Touch Screen reliability?

>> (5) What information should buyers send when requesting a TFT Touch Screen quotation?

China has become one of the most important global hubs for TFT Touch Screen modules, supplying displays for smartphones, industrial HMIs, automotive dashboards, medical equipment, kiosks, and smart home devices. For overseas buyers, understanding the leading TFT Touch Screen manufacturers in China is essential to secure reliable OEM/ODM partners, ensure stable quality, and keep total project cost under control.[1][2][3][4]

Below is an integrated, extended guide to the top TFT Touch Screen suppliers in China, how to choose the right partner, and how to apply TFT Touch Screen technology in different industries.

A TFT Touch Screen combines a TFT LCD panel (Thin‑Film Transistor Liquid Crystal Display) with a touch sensor such as capacitive or resistive technology, plus a cover lens and control electronics. This integrated TFT Touch Screen module can show high‑resolution images while simultaneously detecting user input by finger, stylus, or glove.[2][4][5][1]

A typical TFT Touch Screen module includes:

- TFT LCD cell (glass with TFT array and liquid crystal)

- LED backlight unit with light guide and optical films

- Touch sensor layer (PCAP capacitive or resistive)

- Cover glass or plastic lens with printing and logo

- Driver ICs and interface (RGB, LVDS, MIPI, eDP, SPI, MCU)

This structure allows a TFT Touch Screen to deliver vivid images, fast response, and accurate touch control in a compact, robust package suitable for mass production.[1][2]

China concentrates a complete TFT Touch Screen supply chain, from TFT glass and polarizers to touch sensors, FPCs, driver ICs, and module assembly. Large panel makers and hundreds of small‑ and medium‑sized module factories together provide both standard TFT Touch Screen products and highly customized industrial solutions.[3][4][2][1]

Key advantages of Chinese TFT Touch Screen manufacturers include:

- Mature G5–G10.5 TFT LCD production lines for small to very large sizes.[2][1]

- Strong engineering teams for custom TFT Touch Screen design, firmware, and structure optimization.[6][3]

- Competitive pricing combined with ISO‑certified quality systems and multi‑stage reliability testing.[4][6]

This ecosystem makes China a preferred sourcing base for global brands that require high‑volume consumer TFT Touch Screen panels as well as niche industrial TFT Touch Screen modules.[4][1]

The list below highlights 10 representative TFT Touch Screen and TFT display manufacturers in China that frequently support integrated touch modules or custom TFT Touch Screen assemblies.[1][2][4]

BOE is the largest TFT LCD and AMOLED producer in China and a key supplier of TFT Touch Screen panels for mobile devices, tablets, laptops, and monitors. BOE provides TFT panels and on‑cell or in‑cell touch solutions that many downstream module factories integrate into final TFT Touch Screen products for industrial and automotive applications.[7][2][1]

Typical strengths of BOE's TFT Touch Screen offering include wide product coverage from small to ultra‑large sizes and advanced technologies such as high‑refresh, low‑power, and wide‑gamut panels. BOE is often the first choice when a project demands stable long‑term supply and cutting‑edge TFT Touch Screen performance.[7][2][1]

TCL CSOT is a leading TFT LCD and OLED panel manufacturer, especially strong in TV and large‑size displays, but also active in notebook and tablet TFT Touch Screen markets. Many Chinese module makers purchase CSOT TFT cells and add custom touch sensors and cover lenses to make complete TFT Touch Screen modules for branded customers.[2][4][1]

CSOT offers advanced oxide and LTPS TFT panels that can be combined with capacitive touch for high‑resolution TFT Touch Screen devices. This makes CSOT suitable for premium monitors, tablets, and commercial displays where image quality is critical.[4][1][2]

Tianma focuses on small‑ and medium‑size TFT LCDs and has become a benchmark supplier for automotive, industrial, and medical display applications, often combined with touch. Its factories can supply TFT LCD and TFT Touch Screen modules with high brightness, wide temperature range, and specialized shapes for automotive instrument clusters and industrial HMIs.[6][1][2]

Tianma's TFT Touch Screen portfolio covers both consumer‑grade and automotive‑grade solutions with extended lifetime and enhanced reliability. For buyers who need robust TFT Touch Screen displays for medical or vehicle use, Tianma is often shortlisted as a strategic partner.[6][1][2]

IVO is one of the earliest Chinese companies to operate a 5th‑generation TFT‑LCD line, focusing on notebook, tablet, and automotive displays. Its panels are widely used as the base for TFT Touch Screen modules assembled by module factories and system integrators.[8][3][1]

IVO offers various mid‑size TFT LCDs that match well with capacitive TFT Touch Screen designs for infotainment and industrial control. For overseas buyers, IVO is attractive when they need stable notebook or automotive TFT Touch Screen supply from a proven panel maker.[3][8][1]

AV‑Display is a specialized TFT LCD and TFT Touch Screen module manufacturer, offering color TFT modules, capacitive touch panels, and custom HMI display solutions. The company places emphasis on industrial control, home automation, and automotive‑grade TFT Touch Screen devices that require long product life cycles.[9][4]

AV‑Display's strength lies in tailor‑made TFT Touch Screen modules from around 1.8″ to over 10″ with optional PCAP touch and customized interfaces. For OEMs that need a dedicated engineering team to co‑develop a TFT Touch Screen for a specific machine or appliance, AV‑Display is a capable choice.[9][4]

Kingtech is recognized as a flexible TFT display and TFT Touch Screen manufacturer focusing on small to mid‑size industrial displays. It combines TFT LCD modules with resistive or capacitive touch panels to deliver complete TFT Touch Screen solutions for medical devices, smart home panels, and industrial controllers.[4]

Kingtech is known for accepting lower minimum order quantities on custom TFT Touch Screen projects compared with large panel makers. This is useful for startups and niche equipment builders that need customization but cannot commit to huge annual volumes.[4]

Sunul is an ISO‑certified LCD and TFT display supplier with experience in sunlight‑readable and high‑brightness panels. Many of its projects involve TFT Touch Screen modules for outdoor terminals, parking systems, marine equipment, and industrial HMIs.[4]

Sunul focuses on reliability and environmental resistance, supporting TFT Touch Screen modules that work under direct sunlight, low temperature, or high humidity. For outdoor kiosks and rugged devices, its high‑brightness TFT Touch Screen solutions are especially valuable.[4]

DWIN is well known for intelligent TFT Touch Screen modules with built‑in MCU, GUI tools, and firmware, popular in smart appliances and industrial control. Its smart TFT Touch Screen products allow customers to design UI screens quickly without deep embedded programming knowledge.[10][1][4]

DWIN integrates TFT display, capacitive touch, and a powerful controller into a single TFT Touch Screen system that communicates via serial or industrial interfaces. This “all‑in‑one” approach helps reduce development time and simplify wiring for equipment manufacturers.[10][4]

Ruixiang specializes in industrial TFT displays and touch solutions, offering TFT Touch Screen products with wide temperature range, high brightness, and rugged construction. The company supplies many industrial control, transportation, energy, and medical equipment manufacturers.[6]

Ruixiang's core advantage is its focus on customized industrial TFT Touch Screen modules that withstand shock, vibration, and long‑term operation. It can adjust cover glass thickness, surface treatment, and bonding methods to meet demanding specifications.[6]

ChengHao focuses on small LCD touch screens and TFT LCD display modules, supporting custom TFT Touch Screen solutions for handheld devices, smart meters, and POS terminals. Their portfolio includes mini‑size TFT Touch Screen modules with various interfaces for IoT and embedded applications.[11]

ChengHao is suitable for compact product designs where space is limited but a color TFT Touch Screen is still required. By tailoring FPC layout, mechanical outline, and interface, the company can align its TFT Touch Screen modules with the customer's printed circuit board and housing.[11]

A Chinese TFT Touch Screen manufacturer can support a wide range of industries by tuning brightness, touch type, and mechanical design. Common application fields include:[1][6]

- Industrial HMI panels and PLC operator terminals using rugged TFT Touch Screen modules.

- Medical devices, diagnostic equipment, and patient monitors needing bright, low‑EMI TFT Touch Screen interfaces.[1][4]

- Automotive dashboards, center stacks, and rear‑seat entertainment using curved or special‑shaped TFT Touch Screen displays.[8][1]

- Retail kiosks, POS, vending machines, and ticketing terminals using mid‑size TFT Touch Screen systems.[5][6]

- Smart home panels, thermostats, and security terminals built around compact TFT Touch Screen modules.[11][4]

As Industry 4.0, automotive digitalization, and smart home devices continue to grow, demand for reliable TFT Touch Screen interfaces will keep rising globally.[1][4]

When working with a TFT Touch Screen manufacturer in China, one of the first decisions is whether to use capacitive or resistive touch.[5][1]

A projected capacitive (PCAP) TFT Touch Screen uses an electrode matrix to detect changes in capacitance caused by a finger or conductive stylus. It supports multi‑touch, gestures, and thick protective glass, making it ideal for smartphones, tablets, kiosks, and modern HMIs.[5][6]

Advantages of capacitive TFT Touch Screen modules include high transparency, smooth glass surface, and fast, accurate touch response. However, sensitivity to water and the need for conductive contact should be considered in dirty or wet environments.[5][6]

A resistive TFT Touch Screen uses two conductive layers separated by spacers; pressure causes contact and changes resistance. It works with finger, stylus, or glove, providing reliable operation even when the surface is dusty, oily, or wet.[5][6][1]

Resistive TFT Touch Screen technology is preferred in some legacy industrial devices and cost‑sensitive projects where multi‑touch and optical clarity are less critical. Many Chinese manufacturers offer both capacitive and resistive TFT Touch Screen options so customers can select the best solution for their environment.[5][6]

To evaluate and compare TFT Touch Screen solutions, buyers should consider not only screen size and resolution but a full set of performance parameters.[1][4]

Important parameters include:

- Brightness (luminance): Standard indoor TFT Touch Screen modules may offer 250–350 cd/m², while outdoor or semi‑outdoor designs require 700–1000+ cd/m².[6][4]

- Contrast ratio and viewing angle: IPS‑type TFT Touch Screen panels provide wide viewing angles and better color consistency, essential for premium devices.[1][4]

- Response time and refresh rate: Faster response and higher refresh are important for gaming, video, and automotive TFT Touch Screen applications.[2][1]

- Touch accuracy and latency: High‑quality TFT Touch Screen modules deliver precise touch tracking and low latency for smooth user experience.[5][6]

- Operating temperature range: Industrial TFT Touch Screen modules may operate from around ‑20 °C to +70 °C or wider, depending on materials and design.[6][5]

By clearly specifying these parameters at the RFQ stage, buyers help suppliers choose suitable TFT Touch Screen structures and materials.[3][6]

Choosing the right TFT Touch Screen partner involves checking technical capability, quality system, and service. Key evaluation steps include:[4][1]

- Verify certifications such as ISO 9001, IATF 16949 (for automotive), and ISO 13485 (for medical) related to TFT Touch Screen production.[6][4]

- Review reliability test reports, including high/low temperature, thermal cycling, humidity, vibration, ESD, and salt spray for the TFT Touch Screen modules.[4][6]

- Examine sample TFT Touch Screen units for brightness uniformity, touch accuracy, viewing angle, color consistency, and mechanical strength of the cover lens.[11][4]

- Clarify engineering support, including schematic reviews, mechanical drawings, and firmware tools for intelligent TFT Touch Screen products.[10][4]

It is also wise to compare several TFT Touch Screen manufacturers on price, lead time, minimum order quantity, and after‑sales support before making a decision.[3][6]

Chinese suppliers are particularly strong in custom TFT Touch Screen design and flexible manufacturing. Typical customization parameters include:[3][6]

- Size and resolution: From sub‑2.0″ wearable TFT Touch Screen modules to over 10″ industrial panels with HD or FHD resolution.[11][4]

- Brightness and optical enhancement: Use of special backlight design, reflective films, and optical bonding to improve outdoor readability for TFT Touch Screen modules.[6][4]

- Interface: RGB, LVDS, MIPI, SPI, MCU, or serial interfaces, depending on whether the TFT Touch Screen is a raw display or an intelligent module.[10][4]

- Touch type and structure: PCAP multi‑touch or resistive TFT Touch Screen with tailored glass thickness, cover shape, and mounting method.[5][6]

- Mechanical design: Custom bezels, brackets, gaskets, and sealing to integrate the TFT Touch Screen into enclosures.[11][6]

A well‑managed TFT Touch Screen manufacturer can provide rapid prototypes, iterate based on feedback, and then move to pilot and mass production once the design is frozen.[4][6]

A standard TFT Touch Screen OEM/ODM project usually follows these stages with a Chinese manufacturer:[10][3]

The buyer provides a clear specification document, including display size, resolution, brightness, viewing angle, working temperature, and TFT Touch Screen type.[5][6]

The manufacturer proposes one or more TFT Touch Screen configurations, with mechanical drawings, key parameters, and estimated pricing.[3][6]

Engineering samples of the TFT Touch Screen are produced for integration and validation under real working conditions.[6][4]

Based on test results, the supplier adjusts touch sensitivity, firmware, FPC length, or cover lens design to achieve the best TFT Touch Screen performance.[10][4]

A pilot batch of TFT Touch Screen modules confirms process stability before full‑scale production and long‑term delivery.[4][6]

Close communication at each step reduces risk and ensures that the final TFT Touch Screen solution fits the application and budget.[3][6]

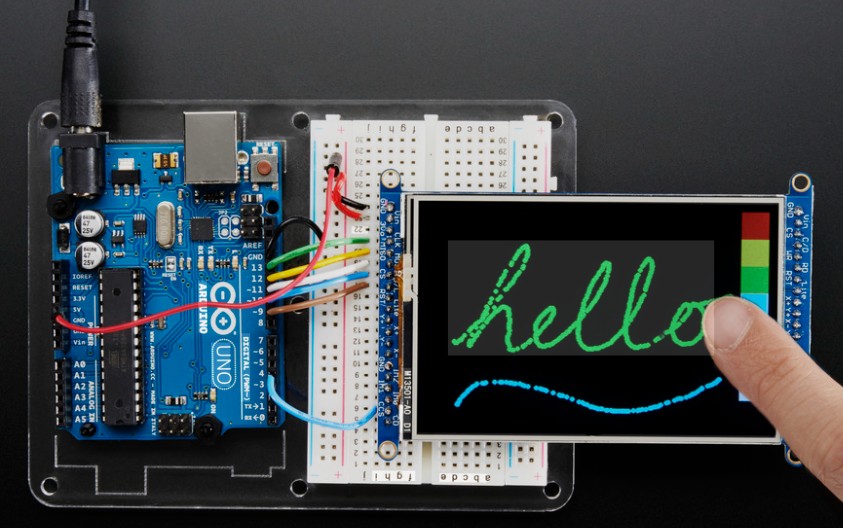

When publishing a marketing article or product page about TFT Touch Screen manufacturers in China, adding images and videos helps visitors better understand your capabilities. Consider using:[6][4]

- High‑resolution photos of TFT Touch Screen modules in multiple sizes, showing both front view and side profile.

- Factory photos of SMT lines, optical bonding equipment, clean rooms, and AOI inspection used in TFT Touch Screen production.

- Application scenes: industrial control panels, automotive dashboards, medical devices, POS terminals, and smart home panels powered by TFT Touch Screen solutions.

- Short videos showing touch responsiveness, multi‑touch gestures, outdoor readability, and rugged reliability tests on TFT Touch Screen modules.

- Animated explainer clips that illustrate how a TFT Touch Screen stack is built from TFT glass, backlight, touch sensor, and cover lens.

These visual assets highlight technical strength and give overseas buyers confidence in your TFT Touch Screen manufacturing capability.[4][6]

Although TFT Touch Screen products are electronic modules, they also rely on supporting materials and processes where abrasives and refractory materials are important.[12][1]

- Precision grinding and polishing are used in TFT glass cutting and edge finishing, where fine abrasives help achieve smooth and safe TFT Touch Screen edges.[13][12]

- High‑temperature kilns and furnaces for glass and ceramic components rely on refractory materials to maintain stable performance during TFT Touch Screen manufacturing.[12]

Suppliers of high‑quality abrasives and refractory materials can indirectly support TFT Touch Screen manufacturers by improving process stability and yield in cutting, polishing, and thermal processing steps.[13][12]

TFT Touch Screen technology is at the heart of modern human–machine interaction, and China provides one of the most complete ecosystems for designing and producing these modules at scale. From large panel makers like BOE and TCL CSOT to specialized module suppliers such as AV‑Display, Kingtech, DWIN, Ruixiang, and ChengHao, overseas buyers can find TFT Touch Screen partners for almost every application scenario.[2][1][6][4]

By clearly defining requirements, comparing multiple TFT Touch Screen manufacturers, and paying attention to reliability testing and customization capability, buyers can secure long‑term, stable cooperation with Chinese suppliers. Combining strong TFT Touch Screen modules with high‑quality supporting materials and robust system design will help you deliver reliable, user‑friendly products in global markets.[3][6][4]

The most important factors are technical capability, quality certifications, reliability testing, and communication efficiency. Check whether the TFT Touch Screen manufacturer has relevant ISO and, if needed, automotive or medical certifications, and ask for test reports and reference projects before final selection.[1][6][4]

Most specialized factories in China can provide custom TFT Touch Screen modules, including size, resolution, brightness, interface, touch type, and cover lens design. Buyers should prepare detailed specifications and be ready to approve mechanical drawings and engineering samples before mass production.[3][6][4]

For existing standard TFT Touch Screen modules, lead time is often several weeks depending on stock and production load. Custom TFT Touch Screen projects require extra time for design, tooling, and validation, so total lead time can range from roughly 8 to 16 weeks or more.[10][3][6][4]

Serious manufacturers perform a full set of reliability tests on TFT Touch Screen modules, including high/low temperature storage, thermal cycling, humidity, vibration, ESD, and sometimes salt spray or UV exposure. These tests help confirm that the TFT Touch Screen will remain stable under the actual operating environment of the end product.[6][4]

Buyers should provide size and resolution, brightness, viewing angle, interface, working temperature, touch type (PCAP or resistive), and any special mechanical requirements for the TFT Touch Screen module. Sharing application photos or mechanical drawings of the end device also helps the manufacturer optimize the TFT Touch Screen design for performance and cost.[3][4][6]

[1](https://eagletp.com/top-10-tft-lcd-manufacturers-in-china/)

[2](https://www.szmaclight.com/new/LCD-manufacturers-in-China-display-module.html)

[3](https://ensun.io/search/tft-lcd/china)

[4](https://www.goldenvision-lcd.com/top-tft-display-manufacturers-in-china/)

[5](https://www.cjtouch.com/industrial-touch-screen/)

[6](https://www.rxtplcd.com/industrial-tft-display/)

[7](https://www.topwaydisplay.com/index.php/en/blog/china-top-10-lcd-manufacturers)

[8](https://www.vetolcd.com/10-Top-LCD-manufacturer-in-China.html)

[9](https://www.av-display.hk)

[10](https://www.dwin-global.com/lcd-tft/)

[11](https://www.chenghaolcd.com)

[12](https://www.disenelec.com/oemodm-china-industrial-lcd-touch-screen-monitor-11-6inch-tft-lcd-display-for-notebook-and-advertising-machine-system-disen-product/)

[13](https://www.panelook.cn/company_yp_list.php?op=list&so_attr=0&ac=supplier&topid=1&secid=38&employee_number=3®ion=45&province=267&st=&page=3)