Views: 222 Author: Wendy Publish Time: 2026-01-02 Origin: Site

Content Menu

● Understanding TFT LCD Technology

● Major TFT LCD Manufacturers and Suppliers in Australia

>> 4D Systems – Intelligent TFT LCD Modules

>> Manuco Electronics – Engineering‑Driven TFT LCD Modules

>> Tekdis – Industrial‑Grade TFT LCD Displays

>> APC Technology and Other Rugged TFT LCD Specialists

>> Maker‑Level TFT LCD Retailers

>> Broadline Catalog Distributors

>> Visual Solution Providers and Digital Signage Integrators

● Typical Applications of TFT LCD in Australia

● How to Select a TFT LCD Partner in Australia

● Practical Sourcing Tips for TFT LCD Projects

● FAQ

>> What is the main advantage of TFT LCD over older LCD technologies?

>> Are Australian companies mainly manufacturers or integrators of TFT LCD?

>> How long is the typical lifecycle of an industrial TFT LCD module?

>> Can TFT LCD modules be customized for branding and special mechanics?

>> What information should be included in a TFT LCD RFQ to suppliers?

Australia has an active ecosystem of TFT LCD manufacturers, integrators, and distributors that serve industrial, commercial, transport, and embedded projects across the country. For global and local OEMs, choosing the right TFT LCD manufacturers and suppliers in Australia can significantly shorten development time, reduce risk, and secure long‑term module availability.

TFT LCD (Thin Film Transistor Liquid Crystal Display) combines an active‑matrix transistor layer with a liquid crystal panel and backlight to deliver sharp images, fast response, and stable brightness. Modern TFT LCD modules in Australia range from tiny 1.4‑inch displays for handheld devices to industrial TFT LCD panels above 20 inches used in HMIs, kiosks, and digital signage.

Key characteristics of TFT LCD modules include:

- Screen sizes from around 1.44 inches to 9 inches in smart modules, and much larger sizes in industrial TFT LCD panels for signage and control rooms.

- Resolutions commonly from 176×220 up to 800×480 and higher, with millions of colours for vivid graphics on TFT LCD screens.

- Interface options such as RGB, SPI, HDMI, LVDS, and embedded controllers in intelligent TFT LCD modules.

For buyers, it is essential to match TFT LCD parameters—brightness, viewing angle, touch type, operating temperature, and lifetime—with the final application environment.

Australia's TFT LCD landscape combines local designers, rugged display manufacturers, specialist distributors, broadline catalog suppliers, and visual solution providers. These companies together cover the full spectrum from maker‑level TFT LCD modules to large, sunlight‑readable industrial displays and integrated systems.

4D Systems is one of the best‑known Australian brands for intelligent TFT LCD modules, headquartered in Australia and serving global customers. The company focuses strongly on smart TFT LCD products that integrate processors, flash, and development tools to simplify GUI design for engineers and product designers.

Key points about 4D Systems TFT LCD solutions:

- Offers the 4DLCD and related series with standard TFT LCD and TFT IPS displays from around 1.44″ up to 9.0″, including capacitive and resistive touch versions.

- Many 4D Systems TFT LCD modules integrate onboard graphics processors, touch controllers, and convenient interfaces, reducing external component count for OEMs.

- Provides development environments, libraries, and sample code that help engineers rapidly design user interfaces on TFT LCD platforms without deep graphics expertise.

For global OEMs, working with 4D Systems can dramatically accelerate prototyping, especially when the product requires a compact TFT LCD with rich graphics, icons, and animations.

Manuco Electronics is a specialist electronics distributor that works directly with major TFT LCD manufacturers to supply standard and custom modules tailored to project needs. Rather than just reselling catalog parts, Manuco focuses on helping customers choose the right TFT LCD configuration for performance, cost, and long‑term stability.

Notable strengths of Manuco in TFT LCD projects:

- Provides a wide portfolio of TFT LCD modules, from small embedded displays to larger industrial panels for machinery and automation systems.

- Emphasizes stable supply and form‑fit‑function compatible TFT LCD choices, helping customers reduce mechanical redesign work when a panel must be updated.

- Can bundle TFT LCD panels with driver boards, cables, touch overlays, and power solutions to create near‑turnkey display subsystems.

This makes Manuco a strong partner for Australian and overseas companies that want an engineering‑driven TFT LCD sourcing strategy rather than pure price‑based purchasing.

Tekdis in Australia provides industrial‑grade LCD and TFT LCD displays designed for harsh, long‑life applications across mining, transport, agriculture, medical, and gaming sectors. Its TFT LCD product range spans from small 3.5″ modules up to very large panels—often above 40″ and even up to around 100″—including specialty shapes like ultra‑wide and square TFT LCD solutions.

Typical features of Tekdis TFT LCD products:

- Uses high‑reliability TFT LCD panels from proven brands for industrial, medical, and commercial‑grade projects.

- Delivers complete TFT LCD solutions with driver boards, touch panels, controllers, metalwork, mounting brackets, and optional embedded PCs for turnkey integration.

- Focuses on long‑term availability, extended temperature ranges, and 24/7 operation, making these TFT LCD systems suitable for mission‑critical environments.

For customers who need rugged and reliable TFT LCD systems rather than bare panels, Tekdis is often a first point of contact in the Australian market.

APC Technology designs and manufactures industrial flat panel displays and panel PCs in Australia, integrating TFT LCD panels into ruggedised housings for sectors such as defence, mining, rail, marine, and heavy industry. These TFT LCD systems are engineered for shock, vibration, dust, moisture, and continuous operation in demanding environments.

Rugged TFT LCD providers in Australia typically:

- Select industrial TFT LCD panels with wide temperature ranges, high brightness, and long backlight lifetimes.

- Design sealed front panels, stainless steel or aluminium housings, and IP‑rated bezels that protect the TFT LCD from harsh conditions.

- Provide custom mounting options, input connectors, and even integrated computing for all‑in‑one HMI solutions.

Such companies are ideal for projects in remote mines, offshore facilities, or military vehicles where commercial TFT LCD monitors would not survive.

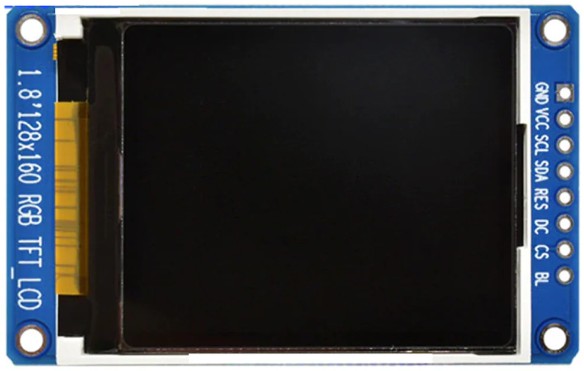

For education, prototyping, and low‑volume projects, Australian retailers such as Maker Store, Pi Australia, and Little Bird supply small TFT LCD modules aimed at makers and students. These modules are typically SPI, I2C, or HDMI TFT LCD boards compatible with platforms like Arduino, Raspberry Pi, and a wide range of microcontrollers.

Typical characteristics of maker‑level TFT LCD modules:

- Compact TFT LCD sizes from around 1.8″ to 3.5″, often combined with simple resistive touch or pushbuttons.

- Bundled cables, breakout boards, and examples that help beginners quickly get a TFT LCD working in lab or workshop settings.

- Ideal for proof‑of‑concept devices and demos before moving to custom TFT LCD designs with industrial suppliers.

This layer of the ecosystem plays an important role in training the next generation of engineers who will later design professional TFT LCD products.

Broadline catalog distributors such as element14 Australia list hundreds of TFT LCD displays and related LCD products, along with technical data, datasheets, and engineering support. Through these platforms, designers can source TFT LCD modules from various global manufacturers with short lead times and low minimum order quantities.

Typical benefits of catalog distributors:

- Access to a very wide range of TFT LCD sizes, resolutions, and interface options for quick evaluation.

- Availability of companion components such as connectors, flat‑flex cables, backlight drivers, and controller ICs for complete TFT LCD designs.

- Online tools, filters, and application notes that help engineers compare TFT LCD brightness, viewing angles, and pinouts before final selection.

These distributors are particularly useful in early design phases and for small production runs.

Visual solution providers such as digital signage companies and AV integrators supply turn‑key systems that rely on large TFT LCD or LCD/LED displays. They often combine commercial‑grade TFT LCD screens with media players, content management systems, mounts, and installation services.

These providers typically:

- Design, install, and maintain TFT LCD signage and information displays in shopping centres, airports, campuses, and transport hubs.

- Offer bright, wide‑viewing‑angle TFT LCD solutions with 24/7 ratings and extended warranties.

- Integrate TFT LCD screens into kiosks, interactive touch totems, menu boards, and conference room systems.

For brands and facility managers, partnering with such companies simplifies deployment of visually impactful TFT LCD networks without needing deep hardware expertise.

TFT LCD technology in Australia covers a wide set of applications, from consumer‑level devices to harsh industrial environments. Understanding these sectors helps OEMs and buyers match TFT LCD specifications to end‑user needs.

Common application areas:

- Industrial and mining HMIs: Rugged control panels, machinery monitors, and vehicle dashboards rely on industrial TFT LCD panels with high brightness and wide temperature capability.

- Medical and laboratory instruments: Diagnostic devices, analyzers, and patient monitors use high‑resolution TFT LCD touchscreens for accurate data display and intuitive operation.

- Transportation and smart city systems: Passenger information systems, timetable boards, and wayfinding kiosks use medium‑to‑large TFT LCD displays for clear visibility in stations and on vehicles.

- Retail, hospitality, and corporate signage: Large TFT LCD or LCD/LED displays deliver menus, promotions, schedules, and branding in dynamic visual formats.

- Embedded systems and IoT devices: Smaller TFT LCD modules provide compact, low‑power graphical interfaces for controllers, handheld tools, and smart appliances.

In each case, TFT LCD parameters such as brightness, contrast, and viewing angle must be tuned to ambient light conditions and viewing distance.

Selecting the right TFT LCD manufacturer or supplier in Australia requires balancing technical, commercial, and life‑cycle considerations. Buyers should clarify their priorities before choosing between intelligent TFT LCD modules, raw panels, or fully integrated display systems.

Key selection criteria include:

- Technical fit: Screen size, resolution, aspect ratio, brightness, colour depth, viewing angle, touch technology, and interfaces must align with the target application and enclosure.

- Environmental performance: For outdoor or industrial projects, check operating temperature, IP rating options, anti‑glare or anti‑reflective coatings, and sunlight readability of the TFT LCD.

- Reliability and lifecycle: Verify availability roadmaps, long‑term manufacturing plans, and policies for second‑source or replacement TFT LCD models to minimise redesigns.

- Engineering support: Ensure access to schematics, 3D models, integration guides, and technical support teams that can assist with EMC, power, and mechanical challenges.

- Customization capability: Ask whether the supplier can customize cover glass, add logos, modify cable lengths, or supply complete rugged TFT LCD assemblies.

- Commercial terms: Evaluate pricing, lead times, minimum order quantities, warranty conditions, RMA processes, and after‑sales support for TFT LCD modules.

A structured selection process—requirements definition, shortlisting, sample evaluation, pilot build, and final approval—helps ensure the chosen TFT LCD partner can support the full product lifecycle.

When sourcing TFT LCD solutions in Australia or from Australian‑based partners, engineering and purchasing teams can follow several best practices:

- Start with a clear specification sheet detailing all TFT LCD requirements, including mechanical, optical, electrical, and environmental parameters.

- Engage potential TFT LCD suppliers early so they can suggest standard or semi‑custom products that meet most needs without heavy redesign work.

- Request evaluation kits or demo boards, especially for intelligent TFT LCD modules, to validate user interface performance and firmware integration.

- Consider futureproofing by choosing TFT LCD families with multiple size and resolution options, simplifying migration if end‑user expectations evolve.

- Include service and support criteria—such as local stock, repair options, and training—alongside unit price when comparing TFT LCD quotations.

These steps reduce risk and help teams build long‑term relationships with high‑quality TFT LCD manufacturers and suppliers in Australia.

Australia has built a strong TFT LCD ecosystem centred on intelligent module designers, rugged display manufacturers, specialist distributors, catalog suppliers, and visual solution providers that together cover almost every industrial and commercial requirement. By working with companies such as 4D Systems, engineering‑oriented distributors, industrial integrators, and signage specialists, OEMs can secure reliable, application‑specific TFT LCD solutions backed by local expertise.

For overseas buyers, partnering with Australian TFT LCD suppliers offers significant advantages in customized design, engineering support, and life‑cycle management, which reduce project risk and accelerate time‑to‑market. When combined with a clear technical specification, structured supplier evaluation, and robust testing, these TFT LCD partnerships provide a stable foundation for modern HMIs, digital signage networks, medical devices, smart city infrastructure, and embedded electronics deployed in Australia and worldwide.

The main advantage of TFT LCD over older passive‑matrix LCD technologies is that each pixel has its own transistor, allowing much faster response times, better contrast, and higher resolutions. This makes TFT LCD ideal for video, complex graphics, and detailed user interfaces in modern industrial and consumer products.

Most Australian companies act as integrators, module designers, rugged system builders, and distributors of TFT LCD rather than fabricating the glass panels themselves. They add value through engineering, customization, and lifecycle support while sourcing TFT LCD panels from global manufacturers.

Industrial‑grade TFT LCD modules often have lifecycles of 5–7 years or more, depending on the panel manufacturer and market segment. Many suppliers offer lifecycle statements and migration paths so that if a TFT LCD model is discontinued, an equivalent replacement can be adopted with minimal design changes.

Yes, many TFT LCD suppliers can customize cover glass printing, bezels, logos, mounting holes, cable lengths, and even optical treatments such as anti‑glare or anti‑reflective coatings. For larger volumes, it is often feasible to design semi‑custom TFT LCD assemblies that perfectly match the product's mechanical and branding requirements.

A good TFT LCD RFQ should include screen size, resolution, brightness, viewing angle, touch requirements, interface type, operating temperature, expected annual volume, target price range, and any special environmental or regulatory needs. Providing this information up front helps suppliers quickly propose appropriate TFT LCD options and accurate quotations.