Views: 222 Author: Wendy Publish Time: 2025-12-29 Origin: Site

Content Menu

● Introduction to TFT LCD in Europe

● Typical TFT LCD Applications in Europe

● Key European TFT LCD Players

>> Tianma Europe GmbH (Germany)

>> Crystal Display Systems (CDS, UK)

>> Distributors, Integrators, and Niche Specialists

● Technology Trends Shaping TFT LCD in Europe

>> High-Brightness and Sunlight Readable TFT LCD

>> Wide Temperature and Ruggedized Designs

>> Touch Integration and HMI Focus

>> Specialty Formats: Bar-Type and Curved TFT LCD

● How Global Supply Chains Support European TFT LCD Users

● Design Considerations When Choosing a TFT LCD Supplier

● The Role of Materials in TFT LCD Manufacturing and Equipment

● Why TFT LCD Remains a Strategic Choice in Europe

>> 1. What is a TFT LCD and how does it differ from a standard LCD?

>> 2. Why do many European industries still prefer TFT LCD over OLED?

>> 3. How can I choose the right TFT LCD supplier in Europe?

>> 4. What are the most important design factors when integrating a TFT LCD into industrial equipment?

>> 5. How do materials such as abrasives and refractories affect TFT LCD manufacturing quality?

Thin-film-transistor liquid-crystal displays (TFT LCD) are the backbone of modern visual interfaces in Europe, powering everything from factory automation panels to medical imaging equipment and vehicle dashboards. TFT LCD technology combines an active matrix of transistors with liquid crystal layers to deliver sharp images, high brightness, and fast response times suitable for demanding professional environments. For international buyers sourcing from TFT LCD manufacturers and suppliers, understanding the local producers, product ranges, and quality standards is the key to successful cooperation.

Europe has developed a mature ecosystem around TFT LCD solutions, with a strong focus on industrial, automotive, medical, and commercial applications. European companies rarely manufacture TFT LCD glass at scale, but they excel at module design, customization, ruggedization, and long-term support tailored to local regulations and industry expectations.

This ecosystem is built on collaboration between global TFT LCD panel makers and European distributors, integrators, and OEMs. European customers benefit from high-reliability TFT LCD modules, extended product lifecycles, and engineering services that bridge the gap between generic panels and fully optimized application-specific displays.

TFT LCD is a type of liquid crystal display in which each pixel is controlled by its own thin-film transistor, hence the name thin-film-transistor liquid-crystal display. This active-matrix arrangement makes it possible to address millions of pixels rapidly and independently, achieving stable images with minimal flicker and good motion characteristics.

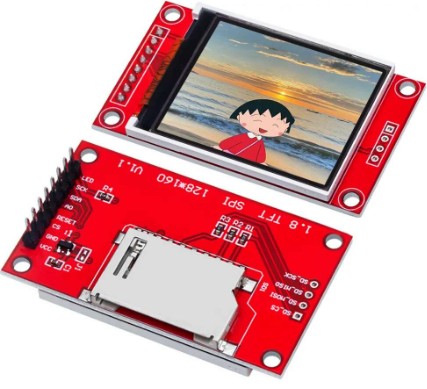

A typical TFT LCD stack includes a backlight unit, polarizers, glass substrates, transparent electrodes, liquid crystal layers, and color filters. When voltage is applied to a pixel's transistor, the orientation of the liquid crystal molecules changes and modulates the amount of backlight that passes through, generating the desired color and brightness.

- High resolution and pixel density for clear graphics and text.

- Stable performance and long lifetime in 24/7 industrial and commercial use.

- Wide availability of sizes, aspect ratios, and interfaces for different system designs.

- Competitive cost structure thanks to a mature global TFT LCD manufacturing base.

These advantages explain why TFT LCD has become the default display choice in many European sectors, even as newer technologies like OLED and MicroLED emerge.

TFT LCD technology is used across a wide range of European industries and end-use scenarios. Its flexibility allows OEMs to design specialized human–machine interfaces (HMIs) and information displays that withstand harsh environments and long duty cycles.

Key European use cases for TFT LCD include:

- Industrial automation: HMIs, PLC panels, SCADA terminals, and machine control panels.

- Medical and laboratory: Patient monitors, diagnostic instruments, imaging systems, and handheld analyzers.

- Automotive and transportation: Instrument clusters, infotainment systems, rear-seat entertainment, EV charger displays, and passenger information systems.

- Retail and kiosks: Point-of-sale terminals, vending machines, ticketing kiosks, ATM and banking terminals, and digital signage.

- Gaming, betting, and amusement: Slot machines, betting terminals, arcade cabinets, and scoreboards.

In all of these categories, TFT LCD modules are often combined with projected capacitive (PCAP) touchscreens, custom cover glass, and embedded computing to create complete, integrated solutions.

The European TFT LCD landscape is dominated by companies that specialize in module design, system integration, and technical support rather than raw panel fabrication. These players add value through optical bonding, touch integration, environmental sealing, electronic interfaces, and configuration management for long-term supply.

Tianma Europe GmbH, headquartered in Germany, acts as the regional hub for one of the world's well-known TFT LCD manufacturers. It focuses on industrial, medical, and automotive TFT LCD applications, providing small to medium-sized panels with high resolution, wide operating temperature ranges, and long lifecycles.

Tianma Europe supports advanced TFT LCD technologies such as high-contrast panels, wide viewing angle solutions, and specialized modes for outdoor readability. European design teams can work with Tianma engineers to select or customize TFT LCD modules with the right interface (LVDS, eDP, MIPI, RGB), brightness level, and mechanical design.

Crystal Display Systems, based in the United Kingdom, is a leading European partner for industrial and commercial TFT LCD solutions. Instead of focusing solely on raw TFT LCD panels, CDS offers a portfolio that includes TFT LCD modules, open-frame monitors, panel PCs, bar-type displays, and high-brightness units.

CDS is particularly strong in custom and semi-custom configurations. Customers can specify brightness, touch technology, mechanical mounting, and environmental protection to match the intended use case. For applications such as outdoor kiosks or transportation signage, CDS can provide TFT LCD systems with very high brightness, optical bonding, and robust enclosures.

E-Service is recognized across Europe as a supplier of open-frame industrial TFT LCD displays and related components. Its core strength lies in designing rugged TFT LCD monitors that can be easily integrated into cabinets for gaming, vending, kiosk, and industrial applications.

By combining high-quality TFT LCD panels with reliable electronics, E-Service delivers displays that are mechanically stable, easy to mount, and built for long-term use. The company's catalog typically includes multiple diagonal sizes, different resolutions, and various signal input options so that OEMs can choose the best TFT LCD configuration for their needs.

Eurocoin Components serves European manufacturers with a wide range of industrial displays, including TFT LCD modules and open-frame monitors. It supports markets such as gaming, transportation, retail, and industrial control by configuring TFT LCD panels into application-ready assemblies.

Eurocoin emphasizes consistent quality and long-term availability, which are critical in regulated or certification-heavy markets. Its TFT LCD solutions often incorporate custom electronics, touch screens, and mounting hardware, enabling OEMs to shorten development time and standardize across product families.

Beyond these well-known brands, Europe hosts numerous distributors and niche integrators that specialize in TFT LCD technology. These companies may not manufacture TFT LCD glass themselves, but they maintain strong relationships with global panel makers and provide value-added services such as:

- Design-in support for TFT LCD modules and touchscreens.

- Optical bonding and lamination services.

- Environmental testing, EMC compliance support, and mechanical validation.

- Lifecycle management and last-time-buy planning for key TFT LCD components.

This layer of specialized partners ensures that European OEMs can always find an appropriate TFT LCD solution, whether they need a standard panel, a heavily customized HMI, or a full “display plus computing” platform.

The European TFT LCD market continues to evolve as end users demand more brightness, better readability, and superior reliability without sacrificing cost-efficiency. Several technical trends are particularly important.

Outdoor and semi-outdoor applications such as EV charging, digital signage, and public transportation require TFT LCD modules that remain readable in direct sunlight. To meet this requirement, manufacturers and integrators offer high-brightness TFT LCD units, sometimes exceeding 1,000 nits or more.

These sunlight-readable TFT LCD modules are usually combined with anti-glare or anti-reflective coatings and, in many cases, optical bonding between the TFT LCD and the cover glass. Optical bonding reduces internal reflections, increases contrast, and improves mechanical robustness, which is especially valuable in environments exposed to vibration or frequent cleaning.

Industrial and automotive applications in Europe often operate in extreme temperature ranges, from cold outdoor conditions to hot engine compartments or factory floors. To serve these markets, suppliers develop TFT LCD modules with extended operating temperature ranges, such as -30 °C to +85 °C, along with ruggedized mechanical designs.

These rugged TFT LCD solutions may include strengthened cover glass, vibration-resistant mounting schemes, conformal coating of electronics, and sealed housings with IP-rated protection. The goal is to maintain consistent TFT LCD performance over thousands of hours of operation in demanding environments.

As control systems become more interactive, projected capacitive (PCAP) touch technology has become standard alongside TFT LCD modules. European suppliers provide integrated TFT LCD plus touch solutions, ensuring precise alignment, optical quality, and controller tuning.

Advanced features such as multi-touch, glove or stylus operation, water rejection, and chemical resistance can be engineered into the front glass and sensor stack. This deep integration of TFT LCD and touch transforms the display into a robust, user-friendly HMI that can withstand heavy, daily use in industrial plants, hospitals, and vehicles.

European designers increasingly use bar-type or “stretched” TFT LCD panels for applications such as passenger information systems, shelf-edge displays, and control panels with constrained space. These TFT LCD modules provide unconventional aspect ratios that can be fitted into narrow or panoramic locations without sacrificing image quality.

Curved and custom-shaped TFT LCD solutions, while more niche, are also emerging in automotive and high-end commercial applications. They allow more ergonomic interfaces and seamless integration into vehicle dashboards or architectural elements.

Although most TFT LCD fabrication lines are located in Asia, European customers depend on global supply chains combined with local expertise. Asian manufacturers produce the raw TFT LCD glass and base modules, while European branches and partners handle regional configuration, warehousing, and engineering.

This split model offers European OEMs the cost advantages of volume TFT LCD production along with localized service. Regional technical teams can advise on panel selection, interface compatibility, and mechanical integration while also managing logistics, quality inspections, and after-sales support.

Furthermore, local partners help mitigate risks associated with product obsolescence. They monitor roadmaps from TFT LCD manufacturers, notify customers of upcoming changes, and coordinate last-time-buy arrangements or drop-in replacements when specific TFT LCD modules reach end of life.

Selecting the right TFT LCD supplier in Europe requires more than just comparing price lists. Engineers and purchasing teams must consider technical, commercial, and lifecycle factors.

Important criteria include:

- Range of TFT LCD sizes and resolutions: From small handheld displays to large panels for dashboards or signage.

- Environmental capabilities: Operating temperature, humidity tolerance, vibration resistance, and IP rating when necessary.

- Optical performance: Brightness, contrast ratio, viewing angles, and outdoor readability.

- Interfaces and compatibility: Support for LVDS, eDP, HDMI, MIPI, or legacy interfaces used in existing equipment.

- Touch integration and front-glass options: PCAP or resistive touch, glass thickness, treatments, and printing.

- Lifecycle and support: Commitments on product longevity, availability of second sources, and engineering assistance.

By carefully evaluating these factors, European OEMs can ensure that their TFT LCD-based products remain competitive, reliable, and serviceable for many years.

While European companies concentrate on displays and systems, the production of TFT LCD panels and related equipment relies heavily on specialized materials. Advanced abrasives, polishing media, and refractory components play a vital role in processes such as cutting, grinding, edge finishing, and high-temperature treatment of glass and metals.

High-quality abrasives are used to achieve precise surface finishes on glass substrates and mechanical parts that interface with TFT LCD assemblies, helping to improve yield and reduce the risk of micro-cracks or contamination. Refractory materials, meanwhile, are essential for furnaces and kilns that operate at elevated temperatures during coating, annealing, or sintering steps associated with TFT LCD production.

A reliable supplier of premium abrasives and refractory solutions can therefore be a strategic partner for TFT LCD panel makers, equipment manufacturers, and integrators. Stable material quality, consistent performance, and application-specific customization support higher throughput, better dimensional accuracy, and longer equipment lifetimes—all of which ultimately enhance the quality and reliability of the final TFT LCD products.

Despite competition from OLED and other emissive technologies, TFT LCD continues to dominate in many professional applications across Europe. Several strategic factors explain this enduring position.

First, TFT LCD has a well-established supply chain and massive global production capacity, which drives costs down and ensures broad availability. For industrial and automotive customers who design products with lifecycles of 7–15 years, this stability is critical.

Second, TFT LCD performance keeps improving. Newer generations offer higher brightness, wider color gamuts, faster response times, and better viewing angles. Many of the perceived gaps between TFT LCD and more recent technologies have narrowed, especially in the segments where power consumption and extreme contrast are less critical than ruggedness and cost.

Third, TFT LCD technology offers unmatched variety. Designers can choose from a huge catalog of sizes, shapes, resolutions, and interface options, then tailor these further with touch, bonding, and mechanical customizations. This flexibility allows European OEMs to create unique, brand-defining experiences while leveraging proven, reliable TFT LCD platforms.

TFT LCD technology remains the foundation of Europe's industrial, automotive, medical, and commercial display landscape, offering a balanced mix of performance, reliability, and cost-effectiveness. European companies such as Tianma Europe, Crystal Display Systems, E-Service, and Eurocoin, together with a wide network of distributors and integrators, convert global TFT LCD panel output into application-ready solutions that meet local standards and long lifecycle expectations.

At the same time, continuous innovation in high-brightness, wide-temperature, and ruggedized TFT LCD modules ensures that this mature technology keeps pace with new use cases and environmental challenges. When combined with advanced materials, precise manufacturing, and expert engineering, TFT LCD will continue to be a strategic and dependable choice for European OEMs seeking stable, long-term display solutions.

A TFT LCD is a liquid crystal display that uses an active matrix of thin-film transistors to drive each pixel individually. This provides faster response times, better image stability, and improved contrast compared with older passive-matrix LCDs, which address pixels in larger groups and typically suffer from ghosting or slow refresh. TFT LCD panels are therefore much better suited for detailed graphics, video, and complex user interfaces.

European industrial and automotive sectors prioritize long product lifetimes, wide temperature ranges, and predictable supply chains. TFT LCD excels in these areas, with proven long-term reliability and a mature global manufacturing base. While OLED can offer deeper blacks and higher contrast, it can be more susceptible to burn-in, has different aging characteristics, and is often more expensive in industrial-grade formats, making TFT LCD a more practical choice for many professional applications.

To choose a suitable TFT LCD supplier, start by matching its product portfolio to your technical needs: screen size, resolution, brightness, operating temperature, and interface. Then evaluate the supplier's capabilities in touch integration, optical bonding, environmental sealing, and customization. Finally, assess lifecycle support, including commitments on product longevity, availability of technical support, and the ability to provide second sources or compatible replacements if specific TFT LCD models are discontinued.

When integrating a TFT LCD into industrial equipment, engineers should consider optical readability (brightness, contrast, and viewing angle), mechanical integration (mounting, bezel design, and vibration resistance), and environmental protection (temperature, humidity, dust, and chemicals). They also need to plan for EMI/EMC performance, power consumption, and compatibility with the system's graphics controller or embedded computer. Properly addressing these design factors helps ensure that the TFT LCD-based HMI remains reliable and user-friendly over years of continuous operation.

Advanced abrasives and polishing materials are critical for precise glass cutting, grinding, and finishing steps in TFT LCD manufacturing. High-quality abrasives help reduce defects, minimize edge chipping, and produce surfaces that bond reliably with other layers. Refractory materials used in high-temperature furnaces must withstand repeated thermal cycles while maintaining dimensional stability and chemical resistance. By using engineered abrasives and refractories, TFT LCD manufacturers and equipment builders can improve yield, extend equipment life, and ensure consistently high-quality display outputs.