Views: 222 Author: Wendy Publish Time: 2026-01-06 Origin: Site

Content Menu

● Overview of Australia's TFT Touch Screen Market

● Leading TFT Touch Screen Partners in Australia

>> 4D Systems – Intelligent TFT Touch Screen Modules

>> Manuco Electronics – Engineering‑Driven TFT LCD and Touch Solutions

>> Tekdis – Rugged Industrial TFT Touch Screen Systems

>> APC Technology – Local Design and Manufacturing of Industrial TFT Touch Screens

>> Dunfield Displays and Other Visual Solution Providers

>> Catalog and Maker‑Level TFT Touch Screen Channels

● Typical Applications of TFT Touch Screens in Australia

● Key Technical Parameters When Choosing a TFT Touch Screen

>> Brightness and Viewing Angle

>> Touch Technology (Resistive vs PCAP)

>> Operating Temperature and Ruggedness

● Extended Considerations for Industrial and Harsh Environments

>> Sunlight Readability and Outdoor Use

>> Mechanical Shock, Vibration, and Mounting

>> Ingress Protection and Cleaning

● Practical Sourcing Tips for TFT Touch Screen Projects

● Example TFT Touch Screen Sourcing Workflow

● FAQ

>> 1. What is a TFT Touch Screen and how does it work?

>> 2. What are the main types of touch technology used in TFT Touch Screens?

>> 3. Why should I source TFT Touch Screens from Australian suppliers?

>> 4. How do I choose the right size and specification for my TFT Touch Screen?

>> 5. Can Australian TFT Touch Screen suppliers support global OEM projects?

Australia has developed a dynamic ecosystem around TFT Touch Screen technologies, combining local manufacturers, integrators, distributors, and solution providers that serve industrial, commercial, and embedded markets. This article profiles key TFT Touch Screen manufacturers and suppliers in Australia, explains major applications, highlights important technical parameters, and offers sourcing tips for global OEMs and buyers.[1]

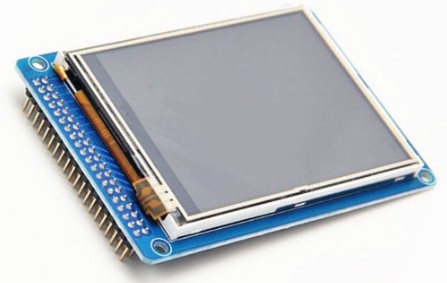

A TFT Touch Screen combines a thin‑film transistor (TFT) LCD display with an integrated touch panel, typically resistive or projected capacitive (PCAP). These integrated modules create intuitive human–machine interfaces (HMI) for industrial equipment, vehicles, kiosks, medical devices, and consumer products.[1]

Key characteristics of a modern TFT Touch Screen include:

- High‑resolution TFT LCD panel for clear images and sharp text.[1]

- Touch overlay (resistive or capacitive) bonded to the display surface.[1]

- Optional controller boards, cover glass, and housings for OEM and industrial use.[1]

A TFT Touch Screen brings visual output and touch input into a single, compact module, which simplifies enclosure design and improves usability. This is why TFT Touch Screen technology has become the default choice for many HMI applications across Australia.[1]

Australia's TFT Touch Screen landscape is built around intelligent module designers, rugged industrial display manufacturers, specialist distributors, catalog distributors, and visual solution providers. Together they support sectors such as mining, transport, defence, medical, gaming, agriculture, and retail.[1]

For global buyers, Australia offers:

- Local engineering support and customisation of TFT Touch Screen solutions for harsh or specialised environments.[1]

- Strong emphasis on rugged, long‑lifecycle displays for mission‑critical equipment and infrastructure.[1]

- Access to global TFT LCD and touch component brands through experienced Australian distributors and integrators.[1]

Many projects combine international TFT Touch Screen manufacturing with Australian system design and field support, creating a practical balance of cost, quality, and responsiveness.[1]

4D Systems is one of the best‑known Australian brands focused on intelligent TFT display modules and smart HMI solutions. The company designs modules that integrate a TFT LCD, controller, processor, and development tools, greatly simplifying TFT Touch Screen GUI design for engineers and product developers.[2]

Typical advantages of 4D Systems for TFT Touch Screen projects include:

- Intelligent TFT modules with on‑board graphics processors, flash memory, and software tools for rapid GUI development.[2]

- Support for serial, SPI, and other embedded interfaces widely used in industrial and IoT devices.[2]

- A global distribution network serving OEM customers well beyond Australia's borders.[2]

These intelligent TFT Touch Screen modules reduce firmware complexity, shorten development cycles, and are well suited to compact embedded products where engineering resources are limited.[2]

Manuco Electronics has been active in display technology for decades and works closely with key TFT LCD manufacturers to supply modules and integrated display systems. Its portfolio covers LCD panels, TFT modules, and TFT Touch Screen assemblies for industrial and commercial applications.[3][4]

Important capabilities for TFT Touch Screen buyers include:

- Broad range of TFT LCD modules from small embedded displays to larger panels for automation and machinery.[4]

- Ability to combine TFT panels with driver boards, touch overlays, cables, and power solutions for near‑turnkey TFT Touch Screen subsystems.[4]

- Focus on long‑term availability and form‑fit‑function compatible replacements to minimise redesign when panels change.[4]

This engineering‑driven approach helps OEMs maintain stable TFT Touch Screen platforms over many years, even as base panels evolve.[4]

Tekdis supplies industrial‑grade TFT LCD and touch displays for harsh, long‑life applications across mining, transport, agriculture, medical, and gaming. Its product range includes industrial monitors, panel PCs, and open‑frame TFT Touch Screen systems from compact modules to very large sunlight‑readable panels.[5]

Why Tekdis is important for TFT Touch Screen sourcing:

- Emphasis on rugged designs with wide operating temperature, vibration resistance, and ingress protection for outdoor and mobile uses.[5]

- Availability of integrated panel PCs combining TFT Touch Screen, CPU, storage, and I/O, reducing integration workload for OEMs.[5]

- Focus on markets such as rail, fleet management, mining trucks, and field service equipment that demand reliable touch HMIs.[5]

For buyers needing a fully integrated, field‑ready TFT Touch Screen computer rather than just a bare panel, Tekdis offers an attractive route to deployment.[5]

APC Technology designs and manufactures flat‑panel displays and panel PCs in Australia, integrating TFT LCDs into rugged housings for defence, mining, rail, marine, and heavy industry. Its systems typically pair a high‑reliability TFT panel with a touch screen and industrial‑grade electronics for 24/7 operation.[6]

Key strengths for TFT Touch Screen projects:

- Local mechanical and electrical design capability to adapt TFT Touch Screen units to specific enclosures, mounting schemes, and environmental requirements.[6]

- Extensive experience with military and transport standards, including shock, vibration, moisture, and EMI considerations.[6]

- Long product lifecycles and service support, essential for critical infrastructure and defence systems.[6]

For mission‑critical applications, a locally designed TFT Touch Screen with proven compliance and service support can be far more valuable than a generic imported display.[6]

Dunfield Displays is an example of an Australian company that focuses on creative display and touch solutions, including TFT display panels and touch assemblies. Providers in this category are ideal for projects that need bespoke TFT Touch Screen designs, special enclosures, or customised visual merchandising.[7]

Typical roles of such visual solution companies:

- Designing kiosks, retail fixtures, or exhibition systems built around TFT Touch Screen technology.[7]

- Coordinating panel, touch, media player, and enclosure into a ready‑to‑install interactive solution.[7]

- Handling installation and lifecycle maintenance for digital signage and interactive displays.[7]

These partners extend TFT Touch Screen usage into retail, museums, showrooms, and public spaces where design and user experience are as important as durability.[7]

Beyond specialist firms, global catalog distributors and local electronics retailers provide ready‑made TFT Touch Screen modules and kits that are ideal for prototyping and low‑volume builds. These channels are popular among R&D teams, education providers, and the maker community.[8]

Common channels for TFT Touch Screen products in Australia include:

- element14 Australia – offers a wide range of TFT LCD displays and TFT Touch Screen products from global manufacturers, including industrial HMIs and small modules.[8]

- Mouser Electronics – supplies TFT LCD display modules and accessories that can be shipped into the Australian market.[9]

- Little Bird Electronics – provides maker‑level TFT Touch Screen displays such as HDMI touch screens for Raspberry Pi and other single‑board computers.[10]

Using these channels, engineers can quickly evaluate various TFT Touch Screen sizes, resolutions, and controllers before standardising on a long‑term solution.[8]

The Australian market deploys TFT Touch Screen solutions in many sectors where intuitive, reliable interfaces are essential. Common use cases include:[1]

- Industrial automation and process control panels, SCADA terminals, and HMI stations in factories and plants.[1]

- Mining and construction machines with rugged TFT Touch Screen displays in cabins and control rooms.[5]

- Transport (rail, bus, marine) driver consoles, ticketing kiosks, and passenger information systems.[6]

- Medical, diagnostics, and laboratory equipment interfaces requiring precise TFT Touch Screen control.[1]

- Retail point‑of‑sale, self‑service kiosks, menu boards, and interactive signage.[7]

In each segment, TFT Touch Screen specifications such as brightness, touch technology, environmental sealing, and mounting standards are tailored to the real‑world conditions.[1]

Selecting the right TFT Touch Screen partner in Australia starts with clearly defining the technical parameters of your application. Key criteria include size, brightness, touch type, ruggedness, and interface.[1]

TFT Touch Screen modules range from compact 3.5‑inch displays used in handheld instruments to large 40‑inch or bigger panels for information kiosks and digital signage. Pixel density must match the viewing distance and level of detail required, especially for data‑rich industrial HMIs.[1]

Outdoor and high‑ambient‑light applications require high‑brightness TFT Touch Screen panels with wide viewing angles. Anti‑reflection coatings and optical bonding can further improve readability in sunlight or harsh lighting.[5]

- Resistive touch: Uses pressure‑sensitive layers, supports stylus and gloved use, and suits simple, cost‑sensitive TFT Touch Screen interfaces.[11]

- Projected capacitive (PCAP) touch: Uses an electrostatic field for multi‑touch support, offers glass‑front finishes, and enables premium user experiences.[11]

The choice of touch technology can determine how a TFT Touch Screen behaves with water, dust, gloves, and different types of user input.[11]

Industrial, mining, and transport environments often demand wide operating temperature ranges and resistance to vibration, shock, and moisture. Rugged TFT Touch Screen designs may include conformal coating, reinforced housings, and high IP ratings for dust and water ingress.[5]

The controller board in a TFT Touch Screen must match the system's host interface and graphics requirements, whether that is RGB, LVDS, eDP, HDMI, or another standard. Matching resolution, refresh rate, and signal integrity is crucial for stable operation.[1]

By defining these parameters clearly, buyers can streamline discussions with Australian TFT Touch Screen suppliers and avoid costly redesigns later.[1]

Industrial and heavy‑duty Australian environments impose additional design requirements on TFT Touch Screen systems. These considerations can significantly impact long‑term reliability and total cost of ownership.[5]

Many mining vehicles, agricultural machines, and outdoor kiosks must keep the TFT Touch Screen readable in direct sun. High‑brightness backlights, transflective TFTs, and advanced coatings are often combined with deep shrouds or hoods to improve outdoor visibility.[5]

Vehicles, rail systems, and plant equipment expose TFT Touch Screen devices to constant vibration and occasional shocks. Rugged mounting brackets, isolation components, and compliance with relevant vibration standards are essential for long‑term stability of TFT Touch Screen units.[6]

Industrial TFT Touch Screen interfaces may be exposed to dust, oils, chemicals, and high‑pressure washing in food and beverage applications. Front panels with appropriate IP ratings, sealed bezels, and chemically resistant cover glass improve the survivability of TFT Touch Screen equipment under regular cleaning.[6]

In sectors such as defence, rail, and medical, TFT Touch Screen systems must comply with EMC, electrical safety, and sometimes explosion‑proof requirements. Australian suppliers experienced in these fields can guide enclosure design, grounding, shielding, and certification testing for TFT Touch Screen products.[6]

When sourcing a TFT Touch Screen solution from Australian manufacturers and suppliers, buyers can follow several best practices to reduce risk and accelerate development.[1]

- Engage early with technical teams: Sharing mechanical drawings, environmental constraints, and UI mock‑ups helps vendors recommend optimal TFT Touch Screen modules and housings.[1]

- Check lifecycle and availability: Industrial TFT Touch Screen projects often need five to ten years of support, so confirm long‑term panel and controller supply commitments.[1]

- Validate certifications and testing: For sectors like rail, defence, medical, and mining, ensure TFT Touch Screen systems meet relevant standards and have proven test reports.[6]

- Request samples and evaluation kits: Prototyping with evaluation boards or demo kits reduces integration surprises and speeds firmware and mechanical design.[2]

- Consider global plus local mix: Some projects benefit from global TFT Touch Screen manufacturers combined with Australian integrators who provide on‑site engineering and support.[1]

By treating the TFT Touch Screen as a long‑term platform rather than a disposable component, OEMs can create families of products that share common HMIs across multiple models and generations.[1]

A typical international OEM or system integrator working with Australian TFT Touch Screen suppliers might follow this sequence.[1]

1. Define project requirements for the TFT Touch Screen, including size, environment, production volume, and certifications.[1]

2. Shortlist Australian partners such as 4D Systems, Manuco Electronics, Tekdis, APC Technology, and selected visual solution providers based on sector fit.[3][2]

3. Share drawings, UI concepts, and performance targets to receive detailed TFT Touch Screen proposals and quotations.[1]

4. Order samples, evaluation kits, or pilot TFT Touch Screen units and perform field testing in realistic conditions.[1]

5. Finalise design, secure supply agreements, and plan long‑term lifecycle management for the chosen TFT Touch Screen solution.[1]

This structured workflow helps organisations turn initial ideas into robust, repeatable TFT Touch Screen platforms that can support multiple projects over many years.[1]

Australia has built a robust ecosystem for TFT Touch Screen technology, spanning intelligent modules, rugged industrial displays, specialised distributors, and creative visual solution providers. By engaging partners such as 4D Systems, Manuco Electronics, Tekdis, APC Technology, and others, global OEMs can secure tailored TFT Touch Screen solutions that meet demanding technical, environmental, and lifecycle requirements.[3][2][1]

Clear specification, early technical collaboration, and realistic field testing enable buyers to choose the right TFT Touch Screen hardware, touch technology, and housing for each project. With the right Australian partners, TFT Touch Screen interfaces can deliver reliable, intuitive control in industries ranging from mining and transport to medical, retail, and public information systems.[1]

A TFT Touch Screen is a TFT LCD display combined with a touch panel that senses user input and sends coordinates to a controller. The TFT layer generates the image, while the touch overlay (resistive or capacitive) detects finger or stylus contact that the system converts into interface actions.[11][1]

The two most common technologies in TFT Touch Screen modules are resistive and projected capacitive (PCAP). Resistive touch uses pressure‑sensitive layers and supports stylus or gloved operation, while PCAP uses an electrostatic field for multi‑touch, glass‑front designs with better optical clarity.[11]

Australian TFT Touch Screen suppliers provide strong local engineering support, customisation, and understanding of harsh environmental conditions such as mining and outdoor transport. They also help manage long‑term availability, compliance, and integration, which is critical for industrial and defence projects.[6][1]

Start by defining viewing distance, available panel space, and required resolution, then match brightness and viewing angles to the ambient light environment. Consult with suppliers about touch technology, temperature range, ingress protection, and interface options to ensure the TFT Touch Screen matches both mechanical and electronic design.[1]

Many Australian TFT Touch Screen companies ship globally and partner with international OEMs, offering design support, documentation, and long‑term supply coordination. By combining Australian engineering with international manufacturing networks, these suppliers can support volume production as well as specialised industrial systems.[2][1]

[1](https://www.reshine-display.com/top-tft-lcd-manufacturers-and-suppliers-in-australia.html)

[2](https://4dsystems.com.au)

[3](https://www.manuco.com.au/who-we-are/)

[4](https://www.manuco.com.au/solutions/tft-lcd-modules/)

[5](https://www.laptoplcdscreen.com.au/industrial-screens.html)

[6](https://www.adept.net.au/news/newsletter/200804-apr/nemacom%20products.shtml)

[7](https://www.dunfielddisplays.com.au/pages/about-us)

[8](https://au.element14.com/c/automation-process-control/panel-displays-instrumentation/human-machine-interface-hmi/touch-screens?meter-display-type=tft-lcd-touch-screen)

[9](https://au.mouser.com/c/optoelectronics/displays/lcd-displays/tft-displays-accessories/?product=TFT+LCD+Display+Modules)

[10](https://littlebirdelectronics.com.au/collections/touchscreens)

[11](https://www.electronic-components.com.au/Products-Services/Riverdi-TFT-Displays/)