Views: 222 Author: Wendy Publish Time: 2026-01-06 Origin: Site

Content Menu

● Why Singapore for TFT Touch Screen Sourcing?

● Major TFT Touch Screen Supplier Types in Singapore

>> Global Electronic Component Distributors

>> Industrial HMI and Panel PC Manufacturers

>> Digital Signage and Large Display Integrators

● Representative TFT Touch Screen Partners in Singapore

● Key Technical Considerations for TFT Touch Screen Projects

>> Size, Resolution, and Aspect Ratio

>> Brightness, Contrast, and Viewing Angle

>> Touch Technology and User Environment

>> Interfaces, Controllers, and Software Support

>> Ruggedness, IP Rating, and Certifications

● How Overseas Buyers Can Work with Singapore TFT Touch Screen Partners

● Typical Applications of TFT Touch Screen Solutions in Singapore

● FAQ About TFT Touch Screen Sourcing in Singapore

>> (1) How do I choose the right TFT Touch Screen size for my project?

>> (2) Are Singapore‑based TFT Touch Screen suppliers suitable for harsh industrial environments?

>> (3) Can Singapore TFT Touch Screen suppliers support small prototype quantities?

>> (4) What information should I send to get an accurate TFT Touch Screen quotation?

>> (5) How do Singapore TFT Touch Screen partners handle after‑sales service?

Singapore has developed a strong ecosystem of TFT Touch Screen distributors, industrial HMI brands, and system integrators that serve automation, transport, medical, and smart-building projects across Southeast Asia and globally. For overseas OEMs, choosing the right TFT Touch Screen manufacturers and suppliers in Singapore helps reduce development risk and ensures reliable long‑term supply with efficient logistics and technical support.[1][2][3]

Singapore is particularly attractive for TFT Touch Screen sourcing because it combines global component access with local engineering, compliance knowledge, and strong project management for industrial and commercial deployments. This makes it a natural bridge between Asian display manufacturing hubs and end‑users across ASEAN, the Middle East, and Europe that require stable TFT Touch Screen platforms.[2][3][4]

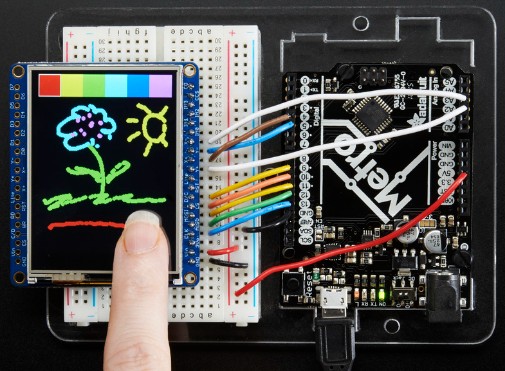

A TFT Touch Screen combines a TFT (Thin Film Transistor) LCD panel with a touch sensor, such as projected capacitive (PCAP) or resistive, plus a controller that converts user touches into digital signals understood by the system MCU or CPU. This integration creates an all‑in‑one human–machine interface (HMI) widely used in industrial control panels, medical devices, kiosks, and smart home equipment where intuitive operation is critical.[5][6][7]

The TFT LCD layer provides full‑color graphics, fast response, and resolutions from QVGA up to Full HD or higher, while the touch layer detects finger or stylus input on the front surface. Optional cover glass, optical bonding, and coatings can make a TFT Touch Screen more robust, sunlight readable, and aesthetically aligned with branding requirements.[6][7][8]

- The TFT LCD sub‑assembly defines size, resolution, brightness, contrast ratio, and viewing angle of the TFT Touch Screen.[7][5]

- The touch sensor determines whether the TFT Touch Screen supports multi‑touch, glove operation, or stylus input and how it performs in wet or dusty conditions.[4][6]

- The controller and interface define how easily the TFT Touch Screen connects to your electronics, including support for LVDS, RGB, MIPI, eDP, SPI, or USB touch communication.[8][6]

Singapore acts as a regional hub that connects global TFT Touch Screen manufacturers with local and overseas OEMs through strong distribution and system integration networks. Instead of mass TFT panel fabrication, Singapore focuses on high‑value engineering, solution design, and after‑sales support for industrial and commercial display projects where reliability and compliance matter.[1][2][3]

Key advantages of Singapore‑based TFT Touch Screen partners include:

- Global brand access: Distributors and solution providers in Singapore offer access to multiple international TFT Touch Screen brands through local stock and technical support teams.[2][3]

- Engineering‑driven solutions: Local integrators combine TFT Touch Screen panels with embedded PCs, I/O, and customized enclosures to create turnkey HMI and panel PC systems for various industries.[4][1]

- Strong logistics and compliance: Singapore's infrastructure supports fast shipping, stable warehousing, and adherence to international safety, marine, and industrial standards for TFT Touch Screen‑based systems.[3][2]

Because many TFT Touch Screen products are imported from manufacturing bases in China, Taiwan, Japan, and other regions, Singapore's role is to curate suitable modules, add engineering value, and ensure smooth deployment for regional projects. This combination is especially attractive for overseas buyers who want the performance of Asian TFT Touch Screen technologies with English‑language communication and predictable service.[1][2][3][4]

Large distributors in Singapore carry broad portfolios of TFT LCD and TFT Touch Screen modules, from tiny 1.3‑inch panels for wearables to 10‑inch and larger modules for industrial control and medical diagnostics. These distributors provide datasheets, evaluation boards, and parametric search tools, making them valuable partners during TFT Touch Screen concept and prototyping stages.[5][6][2]

Typical features of distributor‑supplied TFT Touch Screen solutions include:

- Off‑the‑shelf modules with standard sizes, resolutions, and interfaces, which help reduce development time for standard HMI layouts.[9][6]

- Access to companion components such as backlight drivers, graphics controllers, and connectors that match the chosen TFT Touch Screen panel.[9][5]

- Engineering notes and reference designs that illustrate mechanical mounting, ESD protection, and EMC practices for integrating TFT Touch Screen assemblies.[6][8]

Some Singapore‑based companies specialize in industrial panel PCs and rugged TFT Touch Screen HMIs designed for marine, oil & gas, process control, and building automation environments. These products combine TFT displays, touch sensors, embedded CPUs, industrial I/O, and robust housings tailored for 24/7 operation.[2][4][1]

Key traits of these industrial TFT Touch Screen solutions are:

- Fanless designs with wide‑temperature components, sealed front panels (often IP65 or higher), and vibration‑resistant construction.[10][7]

- Mounting options like panel, rack, or VESA brackets to integrate TFT Touch Screen terminals into cabinets, control desks, or wall mounts.[5][2]

- Long product life cycles with controlled BOMs and formal end‑of‑life notifications to protect the TFT Touch Screen platform over many years.[3][5]

Digital signage and AV integrators in Singapore deploy large TFT and LED displays, video walls, and interactive kiosks in transport hubs, corporate lobbies, and retail venues. They often specify high‑brightness TFT Touch Screen modules in kiosk and wayfinding projects to support interactive user experiences.[11][12][2]

Typical capabilities include:

- Design and integration of indoor and outdoor TFT Touch Screen kiosks with content management systems and network connectivity.[11][2]

- High‑brightness LCD or hybrid solutions with touch overlays that deliver both visual impact and interactivity in public spaces.[12][2]

- Service contracts covering on‑site maintenance, calibration, and replacement of TFT Touch Screen components as content and hardware evolve.[11][2]

Singapore's TFT Touch Screen ecosystem combines local companies and regional branches of global brands to serve different segments of the market. While exact brand lists change over time, several categories of partners consistently appear in sourcing strategies for TFT Touch Screen projects.[1][2][3]

Typical partner groups:

- Local distributors that stock TFT LCD and TFT Touch Screen modules from international manufacturers and support OEM design‑in efforts.[13][2]

- Industrial computing specialists that build panel PCs and monitors based on TFT Touch Screen fronts for control rooms, machines, and ships.[4][1]

- AV and signage integrators that combine TFT Touch Screen technology with media players, mounting structures, and content services.[2][11]

These partners help overseas OEMs by:

- Recommending suitable TFT Touch Screen sizes, brightness levels, and protective glass options based on the application.[4][2]

- Providing local assembly, integration, and burn‑in testing to reduce field failure rates.[1][2]

- Coordinating logistics, export documentation, and after‑sales service for TFT Touch Screen shipments across the region.[3][2]

When planning a TFT Touch Screen project in Singapore, early technical clarity can significantly reduce engineering iterations and supply‑chain risk. The following considerations are commonly used by experienced buyers and project managers when evaluating TFT Touch Screen proposals.[8][6][5][3]

The desired screen size must match both the viewing distance and the available mechanical envelope in the equipment. Common TFT Touch Screen sizes include 4.3", 5", 7", 10.1", 12.1", 15", and 18.5", often implemented in 16:9 or 16:10 aspect ratios for modern UIs.[6][8][5]

Higher resolutions such as WXGA or Full HD provide more UI design flexibility but demand stronger graphics processing and can increase cost. Industrial TFT Touch Screen projects sometimes prioritize long‑term availability over cutting‑edge resolutions to protect product lifecycles.[7][5][6]

Brightness requirements for TFT Touch Screen modules range from about 250–350 cd/m² for indoor devices to 800 cd/m² or higher for outdoor or high‑ambient‑light installations. Wide viewing angles are important in control rooms and multi‑operator environments where users approach the TFT Touch Screen from different directions.[5][6][2]

To ensure readability, many projects in Singapore's sunny climate specify anti‑glare or anti‑reflective treatments on the TFT Touch Screen cover glass. In some cases, optical bonding is used to reduce internal reflections and improve mechanical robustness.[8][6][2][4]

Resistive and projected capacitive are the most common touch technologies for TFT Touch Screen assemblies. Resistive touch supports basic single‑touch input and works with gloved hands or styluses, which suits certain industrial or medical environments.[7][6][4]

Projected capacitive (PCAP) touch offers multi‑touch, gesture recognition, and glass surfaces that feel similar to smartphones, making it popular in kiosks and premium HMIs. However, PCAP‑based TFT Touch Screen designs must consider glove type, water presence, and EMI so that tuning and firmware adjustments can keep performance stable.[6][8][4]

The interface between the TFT Touch Screen and the mainboard can be parallel RGB, LVDS, eDP, MIPI, HDMI, or others, depending on the processor platform. Matching pinouts, timing, and backlight driving requirements is critical to avoid display issues and reduce engineering delays.[8][5][6]

On the touch side, controllers typically communicate via I⊃2;C, USB, or SPI, and require suitable drivers in the operating system. For Linux or RTOS platforms, checking driver availability and kernel support for the chosen TFT Touch Screen controller simplifies development.[5][6][8]

Many TFT Touch Screen projects in Singapore involve industrial, marine, or transport environments where humidity, salt, shock, and vibration are present. As a result, buyers often request IP65 or higher front protection, conformal coating, and wide‑temperature components for the TFT Touch Screen assemblies.[2][4][1]

Certifications such as EMC, marine approvals, or medical safety marks can also be required, depending on the sector. Engaging Singapore partners who understand these compliance frameworks helps ensure the TFT Touch Screen solution passes regulatory testing without costly redesigns.[7][3][1]

Overseas OEMs can leverage Singapore as a central coordination point for TFT Touch Screen projects that involve manufacturing, integration, and deployment across multiple countries. A structured sourcing process reduces misunderstandings and accelerates time‑to‑market.[3][4][1][2]

Recommended steps:

1. Define application and environment

Clearly describe whether the TFT Touch Screen will be used in industrial automation, medical equipment, ships, trains, or retail kiosks and outline operating temperature, humidity, and shock conditions.[1][5]

2. Share mechanical and UI constraints

Provide panel cut‑out dimensions, mounting requirements, bezel design, and basic UI mock‑ups so the supplier can recommend appropriate TFT Touch Screen sizes and form factors.[6][8]

3. Align on performance targets

Set expectations for brightness, lifetime, touch sensitivity, and responsiveness of the TFT Touch Screen, including any requirements for usage with gloves or under sunlight.[2][5]

4. Clarify certifications and standards

For regulated sectors, specify required certifications such as EMC, marine, or medical approvals so they can be considered early in TFT Touch Screen selection and design.[7][1]

5. Prototype, test, and iterate

Build engineering samples or pilot units using the proposed TFT Touch Screen modules and evaluate readability, usability, EMI, and durability in real‑world conditions.[8][6]

6. Plan lifecycle and logistics

Discuss minimum order quantities, safety stock, lead times, and last‑time‑buy policies to secure the TFT Touch Screen supply over the whole product lifecycle.[3][5]

Singapore's TFT Touch Screen ecosystem supports a wide range of industrial and public applications that demand reliability, compact footprint, and modern UI design. Projects often combine imported panels with local engineering and software integration for optimal performance.[4][1][2]

Common application areas:

- Industrial automation and HMI: Machine control panels, SCADA terminals, and building management systems rely on rugged TFT Touch Screen HMIs built into cabinets and control desks.[5][7]

- Marine and transportation: Shipboard navigation and monitoring systems, as well as ticketing and passenger information terminals, use sunlight‑readable TFT Touch Screen displays with high IP ratings.[1][2]

- Retail, banking, and hospitality: Self‑service kiosks, point‑of‑sale systems, and hotel check‑in terminals use large TFT Touch Screen fronts for intuitive customer interaction.[11][2]

- Healthcare and laboratory equipment: Medical analyzers, imaging systems, and lab instruments adopt compact TFT Touch Screen interfaces for parameter setting and data visualization.[6][7]

Singapore is a strategic hub for TFT Touch Screen sourcing, combining global panel manufacturing with local engineering, distribution, and after‑sales support. By working with Singapore‑based distributors, industrial HMI specialists, and AV integrators, overseas OEMs can deploy reliable TFT Touch Screen solutions for industrial, marine, transport, retail, and medical applications with reduced project risk and improved lifecycle stability.[2][3][1]

Careful attention to technical parameters such as size, brightness, touch technology, interface, and ruggedness allows buyers to select the right TFT Touch Screen platform from Singapore's ecosystem. When combined with a structured sourcing process and clear communication, Singapore TFT Touch Screen partners can become long‑term collaborators that support multiple generations of equipment and projects worldwide.[4][8][6][1]

The ideal TFT Touch Screen size depends on viewing distance, the amount of information on each screen, and the available panel space in your enclosure. Smaller devices may use 4.3"–7" TFT Touch Screen modules, while control panels and kiosks often use 10.1"–18.5" or larger formats to display dashboards and complex menus.[8][5][2]

Yes, many Singapore partners focus on rugged TFT Touch Screen HMIs and panel PCs with IP65 fronts, fanless cooling, and wide‑temperature operation for industrial, marine, and outdoor use. These products are designed for 24/7 operation when combined with proper installation and enclosures that match the environmental conditions.[4][1][2]

Distributors and some integrators in Singapore can support low‑volume orders or engineering samples of standard TFT Touch Screen modules for prototyping. For custom or highly specialized TFT Touch Screen designs, minimum order quantities may be higher, but pilot runs and staged ramp‑ups are often possible.[5][6][8][2]

To obtain an accurate quotation, share your target TFT Touch Screen size, resolution, brightness, touch technology, operating temperature, interface, and certification needs, along with mechanical constraints and estimated annual volumes. Clear information allows Singapore partners to propose suitable TFT Touch Screen options quickly and estimate lead times and tooling costs where necessary.[3][8][1][5]

Many Singapore‑based TFT Touch Screen distributors and integrators offer technical support, RMA processing, and spare‑parts planning from local service centers. For large deployments, they may also provide on‑site maintenance, firmware updates, and lifecycle management to keep TFT Touch Screen installations operating reliably over many years.[1][2][3]

[1](https://www.perplexity.ai/search/c4691422-d698-46f1-b3e3-595135a4eadc)

[2](https://www.perplexity.ai/search/18788220-341c-48c7-81e5-40247367cbce)

[3](https://www.perplexity.ai/search/0b6b1a77-1dcb-46e8-9bc2-cd3dead3ae2f)

[4](https://www.perplexity.ai/search/01c951a3-2858-43e1-aebb-3cd28390d7f0)

[5](https://www.perplexity.ai/search/f3f00092-0d72-4f6a-813e-1b0277b1a6c3)

[6](https://www.perplexity.ai/search/08e7d390-4b1a-4ec4-8066-0eb8d064cbab)

[7](https://www.perplexity.ai/search/bafcc7bf-c633-4a85-977e-914d95d01368)

[8](https://www.perplexity.ai/search/2e9f639b-b12c-4887-bb38-80c46aac7dfc)

[9](https://www.perplexity.ai/search/64aac181-5bd5-4975-9de3-7412cfd7d2cd)

[10](https://www.perplexity.ai/search/71603b6e-61cc-40f0-bdcc-ddd482bfa2b9)

[11](https://www.delta-singapore.com/en-SG/products/DLP-LED-and-LCD-Video-Wall/ALL/)

[12](https://www.ascenstar.com/products/digital-displays/)

[13](https://sg.element14.com/c/automation-process-control/panel-displays-instrumentation/human-machine-interface-hmi/touch-screens?meter-display-type=tft-lcd)