Views: 222 Author: Wendy Publish Time: 2026-01-06 Origin: Site

Content Menu

● Swiss TFT Touch Screen Ecosystem

● Technology Features of Modern TFT Touch Screen Solutions

● FELA Management AG and Transportation Displays

● Role of Distributors and Component Channels

● Customization Options for Industrial TFT Touch Screen Projects

● Choosing the Right TFT Touch Screen Partner in Switzerland

● Integration of Swiss Engineering and Asian TFT Touch Screen Manufacturing

● Typical Project Flow for a Swiss TFT Touch Screen HMI

● Benefits of Swiss TFT Touch Screen Solutions for Global OEMs

● FAQ

>> 1. What is a TFT Touch Screen and where is it used in Switzerland?

>> 2. Why choose a Swiss supplier for TFT Touch Screen projects?

>> 3. Can Swiss companies provide custom‑shaped or high‑brightness TFT Touch Screen modules?

>> 4. How do Swiss TFT Touch Screen partners cooperate with Asian manufacturers?

>> 5. What factors should be considered when selecting a Swiss TFT Touch Screen partner?

Switzerland has developed a specialized ecosystem of TFT Touch Screen and display solution providers that focus on high‑reliability industrial, medical, transportation, and infrastructure applications rather than consumer mass markets. These Swiss TFT Touch Screen manufacturers and suppliers typically combine high‑quality TFT panels with local engineering, customization, and system integration to deliver robust Human–Machine Interface (HMI) solutions for global OEMs.

The Swiss TFT Touch Screen industry is built around value‑added services such as optical bonding, custom mechanics, controller design, and long‑term lifecycle management for industrial projects. Many suppliers can deliver complete TFT Touch Screen modules or monitors that integrate the display, touch sensor, cover glass, and embedded electronics in one engineered package.

Typical applications for Swiss TFT Touch Screen solutions include:

- Industrial automation HMIs, PLC control panels, and machine dashboards that require stable operation over many years.

- Passenger information systems, ticketing terminals, and rugged TFT Touch Screen monitors for rail and public transport.

- Medical front panels, diagnostic equipment, and laboratory instruments using sealed TFT Touch Screen interfaces that withstand cleaning and disinfection.

- Smart building, energy, and infrastructure controls where long‑term availability of TFT Touch Screen modules and exact replacements is critical.

To support these applications, Swiss TFT Touch Screen specialists work closely with mechanical designers, electronics engineers, and software teams to ensure that every display matches the enclosure, power budget, EMC requirements, and UI concept. High‑quality mechanical integration of TFT Touch Screen modules helps prevent light leaks, dust ingress, and premature wear in harsh environments.

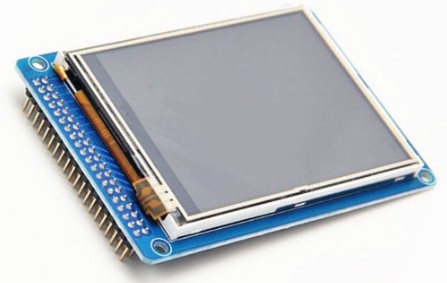

Modern industrial TFT Touch Screen modules used by Swiss manufacturers integrate several important technology features that differentiate them from consumer‑grade devices. These features are essential when designing equipment for demanding professional sectors.

Key characteristics of advanced TFT Touch Screen solutions include:

- Rugged construction with strengthened or chemically tempered cover glass, sometimes combined with anti‑glare and anti‑fingerprint coatings.

- Extended operating temperature ranges for outdoor or unheated environments where TFT Touch Screen displays must remain readable and responsive.

- High‑brightness backlights with precise dimming control, ensuring that the TFT Touch Screen is visible in direct sunlight yet comfortable in low‑light conditions.

- Long‑lifecycle components and stable interfaces so that the same TFT Touch Screen module can be supplied for many years without constant redesign.

Swiss suppliers also pay close attention to EMI/EMC performance, ensuring that the TFT Touch Screen does not interfere with sensitive measurement electronics and that external noise does not affect touch accuracy. This combination of optical, mechanical, and electrical optimization makes Swiss TFT Touch Screen partners attractive for safety‑critical and regulated industries.

FORTEC Switzerland is one of the best‑known Swiss specialists for industrial TFT displays, TFT Touch Screen solutions, embedded computing, and power supplies. The company is positioned as a one‑stop provider that can supply everything from the TFT Touch Screen panel and controller electronics to the embedded CPU platform that drives the HMI.

Key strengths of FORTEC Switzerland for TFT Touch Screen projects include:

- Wide range of TFT displays from small 1.x‑inch modules up to large digital signage sizes, many of which can be combined with capacitive or resistive TFT Touch Screen layers.

- Custom TFT Touch Screen kits with in‑house developed controllers, tailored interfaces, and long‑term availability for industrial and infotainment applications.

- Expertise in drop‑in replacement of obsolete TFT Touch Screen panels, reducing redesign effort and downtime for legacy equipment.

FORTEC Switzerland is frequently selected for applications where a standard display is not enough and the customer needs a complete TFT Touch Screen system ready for installation in a panel, cabinet, or vehicle. Engineering support often covers interface adaptation, firmware configuration for the embedded controller, and optimization of start‑up time and image quality.

DMB Technics is a Swiss display engineering company focused on customized displays and HMI projects, including TN and IPS TFT modules and integrated TFT Touch Screen solutions. Rather than selling only standard catalog parts, DMB Technics emphasizes project‑specific development, with display concepts created in Switzerland and manufactured with selected partners.

Typical capabilities related to TFT Touch Screen products are:

- Custom display modules where the TFT Touch Screen, cover glass, backlight, and mechanical frame are designed around the device's industrial or medical environment.

- Optimization of readability with anti‑reflection coatings, fine‑tuned backlights, and optical bonding for outdoor or high‑ambient‑light TFT Touch Screen applications.

- Support for both resistive and projected capacitive TFT Touch Screen technologies depending on whether gloves, stylus input, or multi‑touch gestures are required.

DMB Technics is often involved from the early concept stage, helping OEMs define screen diagonals, resolutions, and user interaction concepts. By aligning TFT Touch Screen design with overall product design from the beginning, customers can avoid expensive redesigns later and achieve a more intuitive and attractive HMI.

OPTO LOGIC TECHNOLOGY SA is a Swiss company active for more than three decades in the consulting, design, production, and supply of display solutions, including TFT displays and TFT Touch Screen modules. The company combines engineering know‑how with a broad network of panel sources to offer numerous TFT display formats and interface options.

Notable aspects for TFT Touch Screen buyers are:

- Extensive selection of TFT displays that can be paired with capacitive or resistive touch to form complete TFT Touch Screen assemblies for industrial devices.

- Consulting‑driven approach where engineers help OEMs select the optimal TFT Touch Screen size, resolution, brightness, and interface for each project and market.

- Ability to support small and medium production series that require stable TFT Touch Screen availability and tightly controlled engineering changes.

OPTO LOGIC TECHNOLOGY SA is a good match for companies seeking flexible, consulting‑oriented cooperation rather than high‑volume commodity supply. Its role is to transform basic TFT panels into practical, field‑ready TFT Touch Screen solutions with the right mechanics, electronics, and documentation.

CSC Electronic AG is a Swiss supplier of professional displays and touchscreens, offering small to mid‑size TFT modules and TFT Touch Screen components for industrial control and instrumentation. The company works with COG/FOG assembly technologies and provides customization services such as backlight tuning, cable layout changes, and specific connector designs.

Advantages when sourcing TFT Touch Screen solutions from CSC include:

- Focus on handheld and panel‑mount sizes that are common in control units, measurement devices, and portable terminals with TFT Touch Screen interfaces.

- Capability to adapt the mechanical and electrical interfaces of a TFT Touch Screen module to match existing enclosure cut‑outs and PCB layouts.

- Support for integrated touch and bonding processes which enhance optical performance and durability of the TFT Touch Screen in demanding environments.

CSC is often selected by OEMs who need compact TFT Touch Screen modules that can be seamlessly integrated into portable meters, small operator terminals, or DIN‑rail controllers. Its engineering services help customers meet strict form‑factor and connector constraints without compromising screen quality.

FELA Management AG focuses on display monitors for transportation and passenger information systems, supplying ruggedized TFT display and TFT Touch Screen solutions for rail and public transit. These systems prioritize reliability, vandal resistance, and long service life over low cost, making them typical of Swiss high‑value TFT Touch Screen applications.

In transportation, TFT Touch Screen monitors must withstand vibration, temperature variations, humidity, and exposure to cleaning chemicals. Suppliers like FELA design enclosure systems, mounting hardware, and protective glass so that the TFT Touch Screen can remain operational throughout the life of a rail car or station installation. High‑brightness, wide‑viewing‑angle panels ensure that information remains readable for passengers from different positions.

In addition to dedicated manufacturers, Switzerland relies on strong distribution channels that stock TFT displays and TFT Touch Screen components from international brands. Distributors maintain broad ranges of TFT displays, controller boards, cables, and peripheral components that can be combined with local engineering to create finished TFT Touch Screen assemblies.

These distributors provide:

- Fast access to samples and evaluation kits for different TFT Touch Screen sizes, resolutions, and interfaces.

- Logistics services such as safety stock, scheduled deliveries, and last‑time‑buy coordination for long‑lifecycle TFT Touch Screen projects.

- Technical support on controller selection, cable lengths, and signal integrity when integrating TFT Touch Screen modules into complex systems.

By using distributors strategically, Swiss integrators can focus their resources on system‑level design and certification while still benefiting from global supply chains for TFT Touch Screen hardware.

One of the main reasons OEMs choose Swiss partners is the depth of customization available for industrial TFT Touch Screen projects. Rather than being locked into standard modules, customers can tune nearly every aspect of the HMI.

Typical customization options include:

- Mechanical customization: Custom glass shapes, logo printing, special mounting holes, gaskets, and front‑panel designs that match the device's branding and protection requirements.

- Optical customization: Choice of polarizers, anti‑glare or anti‑reflective coatings, optical bonding between TFT panel and cover glass, and backlight optimization for specific lighting conditions.

- Electrical customization: Tailored interface boards for LVDS, eDP, HDMI, or MCU interfaces; custom cable harnesses; and power sequencing aligned with the rest of the system.

- Touch customization: Selection of projected capacitive or resistive technology, tuning for glove operation or water rejection, and firmware adjustments for gesture support on the TFT Touch Screen.

These capabilities make Swiss TFT Touch Screen suppliers particularly attractive for low‑to‑medium volume segments where product differentiation and reliability matter more than the absolute lowest component cost.

When selecting a Swiss TFT Touch Screen manufacturer or supplier, international buyers usually consider several key criteria. A structured evaluation process helps ensure that the chosen partner aligns with technical, commercial, and logistical expectations.

Important factors to evaluate include:

- Application experience: Whether the supplier has a track record in similar sectors such as industrial automation, medical, transportation, or building technology using TFT Touch Screen HMIs.

- Engineering depth: Availability of in‑house mechanical, optical, and electronic engineers who can support custom TFT Touch Screen design and problem solving during the project lifecycle.

- Quality and certification: Compliance with relevant standards for safety, EMC, and environmental performance as well as robust quality systems supporting traceability and testing.

- Lifecycle strategy: Commitment to long‑term availability of TFT Touch Screen modules, clear discontinuation policies, and support for redesigns when components become obsolete.

Buyers often start by ordering development kits or small pilot batches of TFT Touch Screen units for evaluation in realistic operating conditions. Feedback from operators, maintenance teams, and end customers can then be used to refine the design before moving into volume production.

Although Swiss companies lead in system integration and application‑specific engineering, mass production of TFT display glass and many TFT Touch Screen modules remains concentrated in Asia, especially China. Chinese manufacturers of TFT Touch Screen and LCD modules supply a broad range of sizes, interfaces, and brightness options that Swiss integrators can adapt and qualify for local projects.

A common strategy for global OEMs is to combine:

- Swiss engineering partners for specification, prototyping, certification support, and long‑term project management of TFT Touch Screen solutions.

- Established Chinese TFT Touch Screen and TFT LCD factories for cost‑effective volume manufacturing and rapid customization of panels and touch sensors.

This hybrid model allows customers to benefit from competitive manufacturing costs while keeping project control, quality assurance, and application‑level optimization close to their core markets. Swiss companies often take responsibility for incoming inspection, reliability testing, and documentation so that the final TFT Touch Screen subsystem meets European and international compliance requirements.

To understand how cooperation with a Swiss supplier usually evolves, it is helpful to look at a typical TFT Touch Screen project flow from concept to production.

A simplified sequence often looks like this:

1. Requirements analysis

- Define diagonal size, resolution, brightness, operating temperature, IP rating, and expected lifetime of the TFT Touch Screen solution.

- Identify certification constraints and mechanical limitations in the planned enclosure.

2. Concept and sample selection

- Shortlist several TFT Touch Screen options (panel + touch + cover glass) based on initial requirements and budget.

- Order evaluation samples and controller boards to test basic functionality and user experience.

3. Customization and engineering

- Fine‑tune optical bonding, coatings, logo printing, mounting frames, and cable layouts for the selected TFT Touch Screen configuration.

- Integrate the TFT Touch Screen mechanically and electrically into the device, solving EMC, thermal, and sealing challenges.

4. Validation and certification

- Run environmental tests such as vibration, shock, temperature cycling, and humidity on the complete TFT Touch Screen device.

- Perform EMC and safety testing based on target markets and industry regulations.

5. Series production and lifecycle management

- Ramp up volume production with defined quality control plans and traceability for each TFT Touch Screen batch.

- Monitor component availability and proactively manage redesigns or second sources over the life of the project.

This structured process helps ensure that the final TFT Touch Screen HMI is not only visually appealing but also robust, serviceable, and compliant with all relevant standards.

Global OEMs that choose Swiss partners for their TFT Touch Screen subsystems gain several strategic benefits that go beyond the display component itself.

Notable advantages include:

- Reduced project risk due to strong engineering support, disciplined documentation, and predictable communication.

- Higher reliability and user satisfaction thanks to rugged TFT Touch Screen designs tailored to real‑world usage conditions.

- Easier certification and regulatory approval when TFT Touch Screen modules are engineered with compliance in mind from the beginning.

- Better lifecycle control, including clear end‑of‑life notifications, last‑time‑buy options, and assistance in selecting successor TFT Touch Screen models.

These benefits are especially relevant for companies in sectors such as medical devices, transportation, and industrial automation, where redesigns are costly and qualification cycles are long.

Swiss TFT Touch Screen manufacturers and suppliers such as FORTEC Switzerland, DMB Technics, OPTO LOGIC TECHNOLOGY SA, CSC Electronic AG, and FELA Management AG have built a strong niche around industrial‑grade, high‑reliability HMI solutions. By concentrating on engineering, customization, and system integration rather than panel mass production, they offer TFT Touch Screen modules and monitors that are carefully tailored to demanding industrial, medical, and transportation projects worldwide. For buyers that combine Swiss expertise with competitive TFT Touch Screen manufacturing from Asia, it is possible to build robust, long‑lifecycle display solutions that balance performance, reliability, and total cost of ownership.

A TFT Touch Screen combines a thin‑film transistor LCD with a touch sensor, allowing users to control devices by directly interacting with on‑screen elements. In Switzerland, TFT Touch Screen technology is widely used in industrial control panels, passenger information systems, medical devices, smart building interfaces, and specialized laboratory and test equipment.

Swiss TFT Touch Screen suppliers specialize in high‑reliability applications, offering strong engineering support, customization, and lifecycle management instead of commodity hardware. They also provide multilingual technical support and disciplined project management, making them attractive partners for global OEMs that need stable TFT Touch Screen solutions over many years.

Many Swiss display specialists offer customized TFT Touch Screen designs, including special glass shapes, mounting frames, logo printing, and tailored interface boards. They can also specify high‑brightness TFT Touch Screen panels with optimized backlights, optical bonding, and advanced coatings for outdoor or high‑ambient‑light environments.

Swiss companies typically source TFT display panels and some TFT Touch Screen components from major Asian suppliers, then add value through mechanical, optical, and electronic design, system testing, and documentation. This model lets buyers benefit from competitive TFT Touch Screen hardware costs while relying on Swiss engineering for reliability, customization, and regulatory compliance at the system level.

Key factors include industry experience, depth of engineering resources, quality and certification capabilities, and a clear lifecycle strategy for the chosen TFT Touch Screen platform. Buyers should also evaluate the partner's ability to support prototyping, environmental testing, and long‑term logistical planning, ensuring that the TFT Touch Screen solution remains available and supportable for the full life of the end product.