Views: 222 Author: Wendy Publish Time: 2025-12-21 Origin: Site

Content Menu

● Understanding TFT Capacitive Touchscreen Technology

● Core Components of a TFT Capacitive Touchscreen

● Advantages of TFT Capacitive Touchscreen in Industrial and Commercial Use

● Top 10 TFT Capacitive Touchscreen Manufacturers in China

>> AVDISPLAY (Shenzhen AV‑Display Co., Ltd.)

>> Shenzhen SLS Industrial Co., Ltd. (PANASYS)

>> Shenzhen Leadtek Electronics Co., Ltd.

>> DISEN Display (Shenzhen Disen Display Technology Co., Ltd.)

>> Chenghao Optoelectronic (Shenzhen Chenghao Optoelectronic Co., Ltd.)

>> HOTDISPLAY (Touch Panel & TFT Manufacturer)

● Key Selection Criteria for TFT Capacitive Touchscreen Projects

● How to Cooperate Efficiently with Chinese TFT Capacitive Touchscreen Suppliers

● FAQ About TFT Capacitive Touchscreen

>> 1. What is the main difference between a TFT Capacitive Touchscreen and a resistive touch screen?

>> 2. Can a TFT Capacitive Touchscreen be used outdoors?

>> 3. How do I know if a supplier can customize my TFT Capacitive Touchscreen design?

>> 4. What documents are needed before confirming a TFT Capacitive Touchscreen order?

>> 5. How long does it usually take to complete a custom TFT Capacitive Touchscreen project?

China is a global powerhouse for TFT Capacitive Touchscreen modules, supplying industrial, medical, automotive, retail, and smart device brands worldwide with cost‑effective and customizable display solutions. For overseas OEMs and system integrators, selecting the right Chinese TFT Capacitive Touchscreen partner is critical to ensure stable quality, strong engineering support, and long‑term supply capability.

To help buyers make informed decisions, this guide introduces 10 representative TFT Capacitive Touchscreen manufacturers in China, explains their strengths, and provides practical tips for project planning and cooperation. The article also includes a brief summary and a focused FAQ section for quick reference.

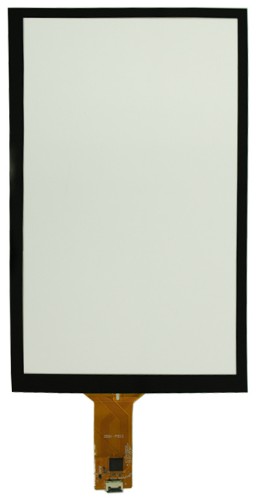

A TFT Capacitive Touchscreen combines a thin‑film transistor (TFT) LCD for image display with a projected capacitive (PCAP) or surface capacitive sensor layer to detect multi‑touch input. This structure allows precise detection of finger location and supports gestures such as zoom, swipe, and rotation, which are standard in modern HMI and consumer devices.

Compared with resistive touch, a TFT Capacitive Touchscreen offers higher light transmission, multi‑finger input, better durability, and a smoother glass surface that enhances user experience. Typical TFT Capacitive Touchscreen modules integrate the LCD cell, LED backlight, capacitive sensor, cover glass, controller IC, and interface (RGB, LVDS, MIPI, HDMI, etc.) into one compact assembly, simplifying integration for equipment manufacturers.

A modern TFT Capacitive Touchscreen is a carefully engineered stack of multiple layers working together as one system. Each layer influences visual quality, touch sensitivity, and mechanical robustness.

- TFT LCD panel: Responsible for image formation, defined by size, resolution, brightness, contrast, and viewing angle.

- Backlight unit: LED‑based system with light guide plate, diffuser, and optical films that drive luminance and uniformity.

- Capacitive sensor: Transparent electrode matrix (usually ITO) laminated above the LCD to detect capacitance changes from the user's finger.

- Cover glass: Thickened glass or tempered glass that protects the TFT Capacitive Touchscreen and provides a pleasant touch surface.

- Touch controller: IC that measures capacitance changes, filters noise, and handles gesture recognition.

- FPC and interface: Flexible printed cable and communication interface (I⊃2;C, USB, SPI, etc.) that link the TFT Capacitive Touchscreen to the main board.

By carefully choosing each component, Chinese manufacturers can tailor TFT Capacitive Touchscreen performance to match different markets, such as industrial HMIs, medical monitors, automotive cockpit displays, and consumer electronics.

For industrial and commercial users, TFT Capacitive Touchscreen solutions provide advantages beyond basic touch capability. Well‑designed modules bring:

- High optical performance: IPS TFT LCDs combined with capacitive touch offer wide viewing angles, high brightness, and excellent color, which are vital for outdoor kiosks and control rooms.

- Durability and reliability: Glass surfaces are more scratch‑resistant than resistive films, and the sealed front of a TFT Capacitive Touchscreen can easily reach IP65 or higher with proper enclosure design.

- Modern UI experience: Multi‑touch, smooth gestures, and attractive UI design support user‑friendly interfaces that reduce training time.

- Flexible customization: Cover glass shape, silk‑printing, logo, anti‑glare treatment, and controller tuning can be customized for specific applications.

These advantages explain why many OEMs gradually migrate from resistive or mechanical keypads to TFT Capacitive Touchscreen interfaces, especially in new product lines.

---

The following companies are widely referenced within the industry for TFT display and PCAP touch solutions and are common partners for OEM and ODM projects. The order is for article structure and not an official ranking.

---

AVDISPLAY is recognized as a leading Chinese supplier of TFT LCD and TFT Capacitive Touchscreen solutions suitable for industrial control, home automation, and automotive sectors. The company offers a wide range of modules from small diagonals to 10.1″ and larger, often combining TFT displays with PCAP touch and customized cover glass.

The manufacturer focuses on high quality and long‑term availability, supported by structured engineering support and standardized documentation. AVDISPLAY's TFT Capacitive Touchscreen modules are used in smart thermostats, medical devices, logistics terminals, and automotive aftermarket systems.

Kingtech is known for supplying flexible and customizable TFT display solutions, including TFT Capacitive Touchscreen modules for embedded, industrial, and smart home projects. Its portfolio spans various diagonal sizes, resolutions, and interface options such as RGB, MIPI, and LVDS.

One of Kingtech's strengths is its willingness to support relatively small MOQs for customized TFT Capacitive Touchscreen designs, making it attractive to startups and niche OEMs. The company frequently cooperates with overseas design houses, adapting mechanical outlines, FPC layouts, and touch parameters to fit compact housings and advanced UIs.

DWIN focuses on intelligent HMI modules and integrated systems that combine TFT displays, TFT Capacitive Touchscreen, GUI software, and application processors. Unlike pure panel manufacturers, DWIN delivers complete HMI platforms, allowing OEMs to implement rich graphical interfaces without deep embedded software development.

Its TFT Capacitive Touchscreen HMIs come with pre‑configured firmware, libraries, and development environments, widely used in vending machines, textile machinery, elevators, medical instruments, and smart home control panels. This “system‑level” offering transforms the TFT Capacitive Touchscreen from a simple component into a full solution.

Operating the PANASYS brand, Shenzhen SLS Industrial supplies TFT display modules and TFT Capacitive Touchscreen solutions for industrial and consumer products. The company runs multiple automated COG and FOG bonding lines, which support stable volume and consistent quality.

PANASYS offers high‑brightness, wide‑temperature modules and carefully engineered PCAP stacks tailored for harsh or outdoor environments. Their engineering teams often cooperate with customers to optimize optical bonding, mechanical assembly, and EMI performance of the TFT Capacitive Touchscreen, especially in industrial HMIs and automotive aftermarket applications.

Sunul Electronic has a long history in display technology and is often associated with high‑reliability LCD and TFT solutions. Its product range includes industrial‑grade monitors, open‑frame displays, and panel kits with TFT Capacitive Touchscreen integration.

The company focuses on long product lifecycles, stable supply, and strict quality control, making it suitable for markets where redesign cycles are slow and regulatory approvals are demanding. Sunul's TFT Capacitive Touchscreen products are seen in outdoor kiosks, marine navigation systems, industrial PCs, and rugged human‑machine interfaces.

Leadtek operates a large‑scale manufacturing facility capable of producing millions of LCD and touch assemblies annually. The firm offers standard and customized TFT Capacitive Touchscreen modules, including smart displays with embedded microcontrollers or interfaces.

Its engineering teams can customize cover glass size, shape, printing, and assembly to match different end‑products. Leadtek's TFT Capacitive Touchscreen solutions often target medical equipment, POS systems, smart retail terminals, and instrumentation, where product stability, EMC performance, and clean visual design are key requirements.

DISEN is a specialist in TFT LCD panels and value‑added services such as backlight design, interface board development, and touch integration. The company highlights its ability to tailor glass dimensions, brightness, interface, and PCAP structure to match customer‑specific demands.

For TFT Capacitive Touchscreen projects, DISEN offers both standard modules and deep customization, including special aspect ratios, asymmetrical outlines, and reinforced cover glass. Its products are widely adopted in small batch industrial devices as well as larger consumer runs, offering a balanced combination of cost and flexibility.

Chenghao specializes in compact TFT LCD and TFT Capacitive Touchscreen modules in mainstream sizes such as 2.8″, 3.5″, 4.3″, 5″, 7″, and 10.1″. Many modules use IPS technology with high viewing angles and can be combined with custom PCAP touch panels and printed cover glass.

With a focus on reliable performance and responsive customer service, Chenghao frequently serves small to mid‑size OEMs in smart home, handheld, and industrial control fields. The company supports OEM/ODM cooperation from concept through pilot run and mass production, making it a practical partner for emerging applications.

HOTDISPLAY focuses on customized touch panels and TFT solutions, including medium and large‑size TFT Capacitive Touchscreen assemblies up to commercial signage dimensions. Its engineering strengths lie in glass processing, coating technologies, and controller tuning.

The company offers anti‑glare and anti‑fingerprint coatings, printed frames, and uniquely shaped glass for special design projects. HOTDISPLAY's TFT Capacitive Touchscreen solutions are widely used in kiosks, ticketing machines, interactive displays, gaming machines, and industrial terminals that require strong visual impact and robust front surfaces.

---

Future Displays is a Chinese TFT and PCAP touch manufacturer known for compact modules like 3.5‑inch and 4.3‑inch IPS TFT Capacitive Touchscreen units with high resolution and attractive color reproduction. These small displays are well suited to handheld terminals, small controllers, and compact instruments.

The company also provides standalone PCAP touch screens that can be paired with different TFT LCD panels for semi‑custom projects, enabling efficient adaptation to various product families. Future Displays targets international customers needing balanced cost, reliable quality, and flexibility in both hardware and mechanical design.

When choosing a Chinese TFT Capacitive Touchscreen manufacturer, overseas buyers should evaluate both technical performance and commercial fit. Important criteria include:

- Display performance

- Diagonal size, resolution, aspect ratio, and brightness.

- Viewing angle technology (TN vs IPS) and color consistency.

- Touch performance

- Number of touch points supported and gesture recognition capability.

- Sensitivity under different conditions, including glove use, stylus input, or light rain.

- Mechanical and environmental characteristics

- Cover glass thickness, hardness, and surface treatments such as anti‑glare or anti‑smudge.

- Operating and storage temperature range, vibration and shock resistance, IP protection level after integration.

- Customization capability

- Ability to modify FPC length and connector type.

- Support for special glass shapes, logo printing, and optical bonding methods.

- Quality system and lifecycle

- Certifications like ISO9001 or sector‑specific standards.

- Long‑term availability plans for the TFT Capacitive Touchscreen panel and controller ICs.

- Logistics, MOQ, and service

- Minimum order quantities suitable for prototype, pilot, and mass production stages.

- Lead times, sample policy, RMA process, and responsiveness in technical support.

A balanced approach is to pre‑select two to three TFT Capacitive Touchscreen suppliers, run parallel sampling, and evaluate both performance and communication quality before committing to long‑term cooperation.

Smooth cooperation can significantly reduce risk, shorten time‑to‑market, and minimize hidden costs. For TFT Capacitive Touchscreen projects, a structured workflow helps both sides.

1. Specification definition

Buyers should prepare a clear specification document summarizing diagonal size, resolution, interface, brightness, operating temperature, mechanical constraints, and expected lifetime. The more precise the requirements, the easier it is for suppliers to recommend a suitable TFT Capacitive Touchscreen module.

2. Concept and proposal stage

Manufacturers can then propose one or more standard or semi‑custom TFT Capacitive Touchscreen options, accompanied by data sheets, drawings, and reference photos. At this stage, engineers often discuss trade‑offs between cost, performance, and tooling investment.

3. Sample, tuning, and validation

After selecting a candidate, the supplier provides engineering samples. Buyers test touch accuracy, viewing performance, EMC behavior, and system compatibility. It is common to fine‑tune touch sensitivity, gestures, and firmware parameters to match enclosure design and use conditions.

4. Pre‑production and mass production

Once the TFT Capacitive Touchscreen passes validation, a pre‑production batch confirms process stability and quality, then mass production begins. Long‑term forecasts and buffer strategies are established to protect against panel EOL (end of life) risks and supply chain fluctuations.

5. After‑sales support and continuous improvement

A strong Chinese partner will provide ongoing support, including parameter updates, replacement models, and quick reaction to field feedback. Buyers should maintain open communication and periodic reviews to ensure the TFT Capacitive Touchscreen solution remains competitive and reliable over the product lifecycle.

China offers a mature and competitive ecosystem of TFT Capacitive Touchscreen manufacturers capable of serving diverse industries, from industrial automation and medical devices to automotive, smart home, and retail systems. Companies such as AVDISPLAY, Kingtech, DWIN, PANASYS, Sunul, Leadtek, DISEN, Chenghao, HOTDISPLAY, and Future Displays provide a wide spectrum of standard and customized TFT Capacitive Touchscreen solutions.

By carefully defining project requirements, comparing technical and commercial parameters, and building long‑term relationships with two or more strategic suppliers, overseas OEMs and system integrators can secure stable supply, optimized performance, and competitive total cost. The TFT Capacitive Touchscreen will continue to be a central component in modern human‑machine interfaces, and partnering with the right Chinese manufacturer is a key factor in project success.

A TFT Capacitive Touchscreen detects changes in capacitance created by a finger or conductive object, while a resistive touch screen measures pressure between layers of conductive film. Capacitive solutions provide higher optical clarity, multi‑touch capability, and a harder glass surface, whereas resistive screens are easier to operate with any stylus but generally offer lower transparency and shorter lifetime.

Yes, many TFT Capacitive Touchscreen modules are specifically designed for outdoor use when combined with high‑brightness backlights, anti‑reflective glass, and robust sealing. Designers should select wide‑temperature, sunlight‑readable TFT panels and confirm that the touch controller and cover glass stack are tuned for expected environmental conditions.

Most professional manufacturers list customization capabilities such as glass size, shape, thickness, printing, brightness, and FPC layout. When requesting a quotation, clearly indicate which parameters must be customized and which can remain standard. If the supplier can provide drawings and suggests appropriate changes, this usually indicates solid customization capability.

Typical documents include a full product specification, mechanical drawings (2D and sometimes 3D), electrical interface description, reliability and test plan, and quality agreement. For customized TFT Capacitive Touchscreen modules, buyers should also review sample inspection reports and, if necessary, certification documents relevant to their industry.

Lead time depends on complexity. Simple adaptations of an existing TFT Capacitive Touchscreen—such as changing FPC length or cover glass printing—may be completed within several weeks from design confirmation to sample delivery. More complex designs requiring new glass tooling, controller tuning, and extensive validation can take several months before entering stable mass production.

Top 10 Multi Touch Capacitive Touchscreen Manufacturers in China

Top 10 Custom Capacitive Touch Screen Manufacturers in China

Top Capacitive Touch Screen Manufacturers and Suppliers in Turkey

Top Capacitive Touch Screen Manufacturers and Suppliers in Vietnam

Top Capacitive Touch Screen Manufacturers and Suppliers in South Korea

Top Capacitive Touch Screen Manufacturers and Suppliers in Japan

Top Capacitive Touch Screen Manufacturers and Suppliers in Italy