Views: 222 Author: Wendy Publish Time: 2025-12-23 Origin: Site

Content Menu

● Why Europe for Custom Touch Screen Displays

● Leading Custom Touch Screen Manufacturers in Europe

>> DISPLAX

>> Riverdi

>> Andivi

>> German Custom Touch Screen Cluster

● Typical Custom Touch Screen Options in Europe

>> Mechanical and Optical Customization

>> Touch Technology and Firmware

>> Electronics, Interfaces, and Integration

● Application Fields for European Custom Touch Screen Displays

>> Industrial Automation and Factory HMI

>> HVAC, Building Automation, and Energy

>> Medical, Laboratory, and Beauty Devices

>> Retail, Kiosks, and Digital Signage

>> Transportation and Outdoor Installations

● How to Select a European Custom Touch Screen Partner

>> Technical Competence and Portfolio

>> Customization Depth and Flexibility

>> Quality Systems and Certifications

>> Logistics, Lead Times, and Cost

● Typical Project Flow for a Custom Touch Screen Display

>> Concept Design and Quotation

>> Design Freeze and Industrialization

>> Mass Production and Life‑Cycle Support

● FAQ – Custom Touch Screen Displays in Europe

>> (1) How do I start a Custom Touch Screen project with a European supplier?

>> (2) What industries benefit most from European Custom Touch Screen solutions?

>> (3) Can European suppliers handle outdoor and harsh‑environment Custom Touch Screen projects?

>> (4) What is the typical lead time for Custom Touch Screen prototypes and mass production?

>> (5) How do European Custom Touch Screen manufacturers support long product lifecycles?

Europe has become a strategic hub for Custom Touch Screen display solutions serving industrial, medical, retail, transportation, and HVAC applications. Global OEMs and system integrators choose European Custom Touch Screen suppliers for their strong engineering capability, long product lifecycles, and strict quality standards.[1][2]

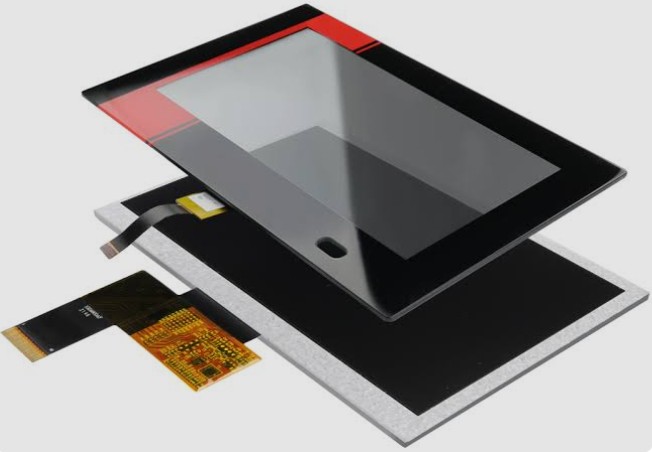

European manufacturers offer Custom Touch Screen solutions that combine rugged design, advanced touch technology, and flexible customization for demanding environments. From projected capacitive (PCAP) to specialized HMI panels, European suppliers can tailor touch size, cover lens, interface, and firmware to match project needs.[3][4]

- High emphasis on reliability for automotive, industrial, and medical projects.[2]

- Strong customization options for Custom Touch Screen size, glass shape, coatings, and interfaces.[5]

- Local engineering support and after‑sales service within the European market.[1]

Several European companies specialize in Custom Touch Screen display solutions, from standalone touch panels to fully integrated HMI devices. These Custom Touch Screen manufacturers support OEMs through concept design, prototyping, certification, and long‑term mass production.[4][5]

FORTEC Group, including its UK operation, focuses heavily on bespoke Custom Touch Screen display assemblies and industrial visualization solutions. The company integrates TFT panels, Custom Touch Screen sensors, optical bonding, and custom mechanics to create optimized display modules for industrial and medical customers.[5]

- Strengths:

- Custom Touch Screen assemblies with high‑brightness backlights and advanced optical bonding.[5]

- Engineering support for mechanical design, EMC, and certification in demanding markets.[5]

- Key applications:

- Industrial HMI terminals, transportation control panels, and medical diagnostic equipment requiring reliable Custom Touch Screen interfaces.[5]

Keetouch GmbH, based in Germany, focuses on industrial touch monitors, open‑frame monitors, and rugged Custom Touch Screen solutions. The company designs Custom Touch Screen devices that withstand continuous operation, making them ideal for factory floors and self‑service installations.[3]

- Strengths:

- Robust open‑frame Custom Touch Screen monitors with VESA and panel‑mount options.[3]

- Support for different touch technologies and front‑glass customization.[3]

- Key applications:

- Factory automation, kiosks, gaming, and retail POS terminals using industrial Custom Touch Screen interfaces.[3]

Dignity Europe is known for its PCAP Custom Touch Screen panels and open‑frame touch monitors from small to very large sizes. It provides full‑custom design, including sensor layout, controller tuning, and cover lens design for each Custom Touch Screen project.[4]

- Strengths:

- PCAP Custom Touch Screen solutions with multi‑touch and advanced controller firmware.[4]

- Engineering service for fine‑tuning sensitivity, glove performance, and noise immunity.[4]

- Key applications:

- Education whiteboards, telecom test equipment, POS systems, and industrial PCs using high‑performance Custom Touch Screen modules.[4]

DISPLAX, headquartered in Portugal, is a specialist in large‑format projected capacitive Custom Touch Screen foils and overlays. Its products enable integrators to build interactive tables, walls, and signage using Custom Touch Screen technology.[6]

- Strengths:

- Large‑format PCAP Custom Touch Screen foils up to very large diagonal sizes.[6]

- Customization for glass thickness, shape, and integration methods.[6]

- Key applications:

- Digital signage, interactive kiosks, wayfinding, and gaming tables based on large Custom Touch Screen surfaces.[6]

Riverdi in Poland designs and manufactures display modules with integrated Custom Touch Screen panels and optional embedded computing. Its portfolio includes both standard and semi‑custom display solutions that can be tailored to customer projects.[7]

- Strengths:

- LCD and TFT modules with PCAP Custom Touch Screen and customizable interfaces.[7]

- Strong design documentation and development kits for easier integration.[7]

- Key applications:

- Medical devices, beauty equipment, industrial control panels, and digital signage using compact Custom Touch Screen displays.[7]

Andivi from Slovenia offers OEM HMI panels that integrate displays, Custom Touch Screen interfaces, and dedicated firmware, especially for HVAC and building automation. It focuses on attractive, intuitive Custom Touch Screen controls for climate systems and building management.[8]

- Strengths:

- Wall‑mounted HMI panels with Custom Touch Screen and tailored UI for HVAC controllers.[8]

- Integration with HVAC, AHU, VAV, heat pumps, and building automation networks.[8]

- Key applications:

- Smart building control, energy management, and HVAC systems with elegant Custom Touch Screen interfaces.[8]

Germany hosts multiple Custom Touch Screen manufacturers and integrators that supply industrial panels and touch modules. These companies design and produce Custom Touch Screen solutions with strong mechanical integration, EMC performance, and industrial compliance.[1]

- Strengths:

- Industrial Custom Touch Screen panels with metal housings, IP‑rated fronts, and extended temperatures.[1]

- Experience in automotive, automation, and transportation markets.[1]

- Key applications:

- Industrial PCs, operator terminals, vehicle HMI systems, and rugged Custom Touch Screen equipment.[1]

European suppliers provide extensive configuration possibilities so each Custom Touch Screen can match the product's mechanical, optical, and environmental demands.[5]

Custom Touch Screen projects usually start with mechanical and optical definitions such as size, shape, and front glass design.[5]

- Panel size and aspect ratio

- From compact 4″–7″ Custom Touch Screen modules to 10.1″, 15.6″, 21.5″, and large signage formats.[6][4]

- Support for standard and ultra‑wide aspect ratios to fit special housings.[7]

- Cover lens design

- Custom Touch Screen glass thickness from ultra‑thin to very thick vandal‑resistant glass.[5]

- Black mask printing, logos, icons, and brand‑specific shapes and colors.[4][5]

- Optical enhancements

- Anti‑glare and anti‑fingerprint treatments for better usability.[5]

- Optical bonding between Custom Touch Screen and display to reduce reflections and improve sunlight readability.[7][5]

Most European Custom Touch Screen projects rely on projected capacitive (PCAP) sensors with flexible firmware customization.[4]

- PCAP controller tuning

- Sensitivity and detection thresholds optimized for finger, glove, or stylus operation.[4]

- Noise rejection settings to handle switching power supplies and RF sources near the Custom Touch Screen.[4]

- Environmental performance

- Custom Touch Screen designs that function in wet conditions, with water‑rejection algorithms.[4]

- Temperature and humidity profiling to ensure stable touch performance over the lifetime of the Custom Touch Screen.[4]

European manufacturers often supply Custom Touch Screen modules with integrated controller boards or even full embedded systems.[5]

- Interface options

- Custom Touch Screen displays supporting LVDS, eDP, HDMI, DisplayPort, or MIPI for display signals.[5]

- USB, I2C, or RS‑232 for touch communication and firmware updates.[4][5]

- Embedded computing

- Some suppliers offer industrial SBCs or panel PCs combined with a Custom Touch Screen and housing.[9][10]

- This reduces integration complexity and shortens time‑to‑market for OEMs.[10]

Custom Touch Screen solutions from Europe are used wherever intuitive, robust human–machine interfaces are required.[2]

In industrial environments, Custom Touch Screen panels must withstand 24/7 operation, vibration, and electrical noise.[3]

- Custom Touch Screen panel PCs and monitors with IP‑rated fronts and metal housings.[1][3]

- Extended temperature and long‑life backlights designed for harsh environments.[3]

Smart buildings rely on elegant Custom Touch Screen interfaces to control HVAC, lighting, and energy systems.[8]

- Wall‑mounted Custom Touch Screen thermostats and room controllers with user‑friendly UIs.[8]

- Integration with building management systems, heating and cooling equipment, and metering devices.[8]

Medical and laboratory equipment require cleanable, reliable Custom Touch Screen interfaces with precise control.[7]

- Custom Touch Screen panels using smooth, chemically strengthened glass suitable for frequent cleaning.[7]

- High‑resolution displays combined with responsive Custom Touch Screen interaction for critical applications.[7]

For customer‑facing systems, Custom Touch Screen solutions must be visually attractive and easy to use.[6]

- Interactive kiosks and ticketing machines with large or mid‑size Custom Touch Screen displays.[6][3]

- Retail POS, self‑checkout, and signage using robust Custom Touch Screen technology.[6]

Transport and outdoor applications require high‑brightness and vandal‑resistant Custom Touch Screen designs.[1]

- Ticketing machines, EV chargers, and parking terminals with sunlight‑readable Custom Touch Screen panels.[2][1]

- Toughened glass and sealed enclosures for resistance to weather and vandalism.[5]

Choosing the right Custom Touch Screen partner in Europe requires a structured evaluation of technology, customization capability, and long‑term support.[5]

The first step is to confirm that the supplier has genuine expertise in Custom Touch Screen design and manufacturing.[5]

- Check if the company designs its own touch sensors, cover lenses, and firmware rather than only reselling standard products.[4][5]

- Review case studies and reference projects in your industry to ensure the Custom Touch Screen partner understands your application.[3][8]

Different projects need different levels of customization for the Custom Touch Screen and surrounding hardware.[4]

- Clarify whether the supplier can adjust glass shape, printing, bonding method, and mechanical tolerances for your Custom Touch Screen.[4][5]

- Confirm the ability to adapt firmware, controller parameters, and UI elements when required.[8][4]

Industrial and medical applications require strict quality systems and compliance.[2]

- Look for ISO‑certified processes and documented procedures for Custom Touch Screen design, testing, and change management.[2][5]

- Check experience with CE marking, EMC testing, and, where relevant, medical or automotive standards.[2][7]

European Custom Touch Screen suppliers can offer advantages in lead time and communication.[3]

- Discuss prototype lead times, sample policies, and typical mass‑production schedules for Custom Touch Screen projects.[8][5]

- Align on forecasts, safety stock, and shipping methods to maintain stable Custom Touch Screen supply.[2][3]

A well‑structured project flow reduces risk and ensures that each Custom Touch Screen design meets technical and commercial targets.[5]

The OEM shares detailed requirements for the Custom Touch Screen at the start of the project.[5]

- Enclosure drawings, user interface concept, operating environment, and expected lifetime.[4]

- Regulatory and certification targets that may impact Custom Touch Screen design and materials.[2]

The supplier prepares one or more Custom Touch Screen concepts for evaluation.[5]

- Proposed panel size, resolution, touch technology, cover lens, bonding method, and electronics.[4][5]

- Budgetary pricing, lead times, and any required tooling charges for the Custom Touch Screen design.[5]

Prototypes of the Custom Touch Screen are built and tested by both parties.[4][5]

- Mechanical fit tests to verify alignment with the housing and gasket design.[5]

- Optical and functional tests to validate brightness, viewing angles, and touch performance of the Custom Touch Screen.[4]

After successful validation, the design is frozen and industrialization begins.[5]

- Final drawings, BOM, and test procedures for the Custom Touch Screen are documented.[5]

- Production lines and quality checks are prepared for volume manufacturing.[3]

The Custom Touch Screen enters volume production and ongoing support is maintained.[3]

- Scheduled deliveries based on forecasts and agreed logistics models.[2][3]

- Life‑cycle management, product‑change notifications, and successor Custom Touch Screen models when needed.[2]

European manufacturers and suppliers of Custom Touch Screen displays provide a valuable combination of technical innovation, high quality, and flexible customization for demanding industries. Their experience in industrial, medical, HVAC, transportation, and retail applications allows OEMs to implement Custom Touch Screen solutions that are reliable, user‑friendly, and compliant with strict regulations.[7][8][3][5]

By selecting a European Custom Touch Screen partner with strong engineering capabilities, proven project references, and robust quality systems, global buyers can reduce development risk and secure long‑term product availability. Clear communication of requirements, careful evaluation of customization depth, and structured project management enable each Custom Touch Screen project to achieve its performance and cost targets.[1][2][4][5]

Most European suppliers begin with a technical meeting to understand your application, enclosure design, and performance goals for the Custom Touch Screen. You will normally be asked to provide drawings, target display size, interfaces, environmental conditions, and compliance requirements so a tailored Custom Touch Screen proposal can be created.[8][4][5]

European Custom Touch Screen solutions are widely used in industrial automation, HVAC and building control, medical and laboratory equipment, retail kiosks, and transportation systems. These sectors value robust Custom Touch Screen designs with long lifecycles, strong EMC performance, and high optical quality.[2][7][8][3][5]

Yes, many European manufacturers offer high‑brightness, optically bonded Custom Touch Screen displays with ruggedized housings and vandal‑resistant glass. Such Custom Touch Screen solutions are designed for outdoor kiosks, EV charging stations, parking terminals, and other exposed environments.[1][2][3][5]

Lead times depend on complexity, but Custom Touch Screen prototypes generally require several weeks to a few months to accommodate design, tooling, and bonding steps. Once the design is frozen, European suppliers usually establish stable Custom Touch Screen mass production with scheduled deliveries aligned to demand forecasts.[2][3][4][5]

European manufacturers use controlled component sourcing, formal change‑notification processes, and documentation to support long‑life Custom Touch Screen designs. When key parts become obsolete, they often propose compatible successor Custom Touch Screen modules or offer last‑time‑buy options to keep customer products in production.[1][7][2][5]

[1](https://ensun.io/search/custom-touch-screen/germany)

[2](https://us.metoree.com/categories/touch-panel/)

[3](https://keetouch.eu)

[4](https://dignity-eu.com)

[5](https://www.fortec.uk/Services/Design-Manufacture/)

[6](https://www.displax.com)

[7](https://riverdi.com)

[8](https://www.andivi.com/oem-hmi-panel-touch-screen-display-for-hvac-ahu-vav-heat-pumps-various-controller-families/)

[9](https://www.rocktech.com.hk)

[10](https://nodka.com)

Top Custom Touch Screen Display Manufacturers and Suppliers in UK

Top Custom Touch Screen Display Manufacturers and Suppliers in Singapore

Top Custom Touch Screen Display Manufacturers and Suppliers in Malaysia

Top Custom Touch Screen Display Manufacturers and Suppliers in USA

Top Custom Touch Screen Display Manufacturers And Suppliers in Europe

Top 10 Multi Touch Capacitive Touchscreen Manufacturers in China

Top 10 Custom Capacitive Touch Screen Manufacturers in China