Views: 222 Author: Wendy Publish Time: 2025-12-30 Origin: Site

Content Menu

● Overview of the TFT Display Market in Saudi Arabia

● How TFT Displays Are Supplied in Saudi Arabia

● Local and Regional TFT Display Channels

>> Industrial HMI and Automation Distributors

>> Regional Display Module Distributors

● Overseas TFT Display Manufacturers Supporting Saudi Projects

>> Custom TFT Display Manufacturers

>> Global Industrial TFT Display Solution Providers

● Typical Applications of TFT Displays in Saudi Arabia

>> Industrial and Energy Sectors

>> Smart Cities, Retail, and Transportation

● Technical Characteristics of TFT Displays for Saudi Conditions

● How Saudi Buyers Select TFT Display Partners

● Cooperation Opportunities for Global TFT Display Manufacturers

● Recommended Sourcing Strategies for Saudi TFT Display Projects

● Example Use Cases of TFT Display Technology in Saudi Arabia

● Content and Media Ideas for Promoting TFT Display Solutions

● FAQ

>> 2. Why are TFT displays popular in Saudi Arabia's industrial projects?

>> 3. How do Saudi companies usually source TFT displays?

>> 4. What should buyers consider when choosing a TFT display supplier for Saudi projects?

>> 5. Can overseas TFT display manufacturers effectively support Saudi customers?

Saudi Arabia is rapidly upgrading its industrial, retail, and smart‑city infrastructure, driving strong demand for reliable TFT display solutions across factories, transportation, energy, and commercial environments. While most TFT display hardware is imported, the Kingdom hosts an expanding ecosystem of distributors, system integrators, and solution providers that connect local projects with global TFT display manufacturers and suppliers.[1]

The Saudi Arabia industrial TFT LCD market is closely linked to large‑scale investments in oil and gas, utilities, logistics, and public infrastructure, all of which require modern visualization and control technologies. Project owners increasingly specify industrial‑grade TFT display and TFT LCD HMI panels that can withstand heat, dust, voltage fluctuations, and continuous 24/7 operation in demanding environments.[1]

Key demand drivers for TFT display projects in Saudi Arabia include:

- Smart factory and Industry 4.0 upgrades requiring HMI panels and industrial TFT display terminals on production lines and process equipment.[1]

- Smart‑city, transportation, and retail deployments using TFT display‑based digital signage, kiosks, and control rooms for real‑time information and advertising.[1]

Because Saudi Arabia imports most of its display technology, local buyers typically source TFT display solutions through:

- Industrial automation distributors that supply HMI panels with built‑in TFT LCD displays from established global brands.

- Regional electronics distributors and display specialists that act as authorized channels for international TFT display manufacturers and module makers serving the Gulf region.[1]

In many cases, overseas TFT display manufacturers provide core TFT LCD modules, while Saudi‑based system integrators design and assemble complete systems around these displays, including metalwork, electronics, software, and networking. This model allows local projects to combine high‑performance TFT display hardware with engineering services optimized for Saudi environmental conditions, language preferences, and regulatory requirements.[1]

Although Saudi Arabia does not yet host many large‑scale TFT display fabrication plants, several important channels supply TFT display and TFT LCD solutions into the Kingdom.[1]

Saudi distributors and regional online platforms supply HMI terminals and industrial TFT display panels that are widely used in:

- Machine control panels and operator stations in food, packaging, and manufacturing plants.

- Process control environments in water treatment, cement, mining, and other heavy industries.[1]

Typical offerings include compact TFT display HMIs for small machines and larger TFT LCD panels for complex processes where multiple variables must be monitored simultaneously. By using such ready‑made HMIs with integrated TFT displays, local manufacturers can modernize equipment quickly without designing their own electronics from scratch.[1]

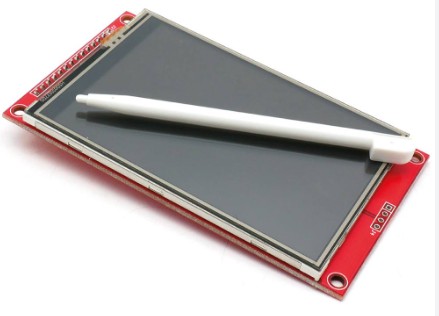

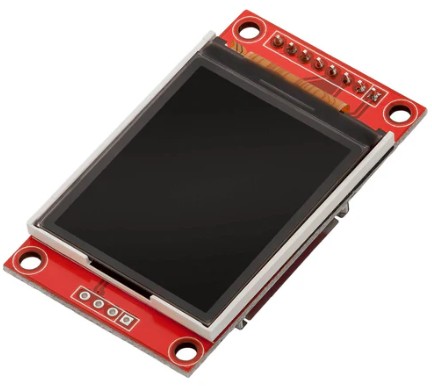

For OEMs and panel builders needing TFT display modules rather than completed terminals, regional distributors in the Gulf cooperate with Asian TFT display manufacturers to stock:

- Small‑format TFT LCD modules for handheld devices, meters, and compact controllers.

- Medium and large‑format TFT display panels suitable for dashboards, medical devices, and industrial consoles.[1]

These channels allow Saudi customers to purchase TFT display modules in small or medium quantities, with technical guidance and local logistics support, instead of managing complex overseas procurement alone. Local access to a wide range of TFT display sizes and interfaces helps engineering teams choose optimal solutions for their designs, from simple monochrome information screens to high‑resolution full‑color TFT LCD panels.[1]

Because the Kingdom imports TFT display hardware, many core TFT display modules originate from international manufacturers, particularly in Asia and Europe.[2]

Several manufacturers provide custom TFT display and TFT LCD solutions that can be integrated into Saudi‑based systems:

- Factories that offer custom TFT LCD display modules with flexible choices of size, resolution, brightness, interface (RGB, LVDS, MIPI, HDMI), and touch options.

- Suppliers that combine TFT display panels with projected capacitive, resistive, or infrared touch technologies to match different industrial usage scenarios.[2]

These overseas factories frequently integrate TFT LCD panels with touch sensors, driver boards, backlights, and connectors, delivering ready‑to‑use TFT display assemblies that Saudi integrators can mount directly into enclosures and cabinets. This approach shortens development cycles and reduces engineering risk for local OEMs that want to deploy TFT display‑based equipment quickly.[2]

Global display solution companies supply industrial‑grade TFT displays and engineering support that also benefit projects in Saudi Arabia:

- Providers of industrial TFT display monitors and open‑frame LCDs designed for control rooms, machine fronts, and kiosks.

- Engineering companies that help customers design full systems around TFT display components, including control electronics, cabling, and mechanical integration.[2]

These global players often work indirectly with Saudi integrators, who select suitable TFT display models and then build complete systems for local end users in industrial, transport, and retail environments. The combination of global TFT display technology and local integration expertise allows Saudi projects to reach high reliability and performance levels.[2][1]

In Saudi Arabia, TFT display technology is used in a diverse range of applications that require clear visualization, robust construction, and often touch interactivity.[2]

Industrial TFT display panels and TFT LCD HMIs appear across:

- Oil, gas, and petrochemical plants, where operators use TFT display terminals in hazardous or outdoor‑exposed control points for process monitoring and alarm management.

- Power generation and water treatment facilities, which rely on large‑format TFT display screens in control rooms for SCADA monitoring and visualization of complex systems.[2]

These applications require high‑brightness TFT display units, extended temperature tolerance, and long product lifecycles to reduce downtime and maintenance efforts in critical infrastructure. Rugged enclosures, sealed front panels, and chemically resistant materials are also common when TFT displays are used in harsh industrial environments.[2]

Beyond factories, TFT display technology plays an important role in:

- Digital signage and LCD display screens for malls, airports, rail stations, and corporate lobbies, where flat TFT display panels deliver sharp image and video playback.

- Ticketing, vending, and information kiosks that use smaller TFT display modules integrated with touch panels to provide interactive interfaces in public spaces.[1]

In transportation, driver consoles and passenger information systems often rely on ruggedized TFT displays able to handle vibration, heat, and continuous operation on buses, trains, and service vehicles. These TFT LCD units commonly feature wide viewing angles and anti‑glare treatments to remain readable under varying lighting conditions.[1]

Saudi Arabia's climate places specific demands on TFT display hardware, especially when installed outdoors or in non‑air‑conditioned industrial spaces.[1]

Key technical characteristics include:

- Brightness and sunlight readability: TFT display panels with higher brightness levels and suitable optical treatments are necessary for outdoor kiosks, dashboards, and signage exposed to strong sunlight.

- Temperature range: TFT LCD modules must operate reliably under elevated ambient temperatures and, in some areas, large temperature swings between day and night.[1]

Other important aspects are:

- Wide viewing angles, which help operators see TFT displays clearly from different positions in control rooms and on machines.

- Long backlight lifetimes and stable color performance, which ensure that TFT display performance remains consistent over years of continuous use in mission‑critical systems.[2]

When Saudi project owners or OEMs choose TFT display partners, they typically evaluate both technical and commercial criteria.[1]

Key technical factors include:

- Resolution, brightness, contrast, viewing angle, and response time of the TFT display or TFT LCD module relative to the intended application.

- Operating temperature range, IP rating (for complete devices), and component quality that determine how well the TFT display will cope with dust, heat, and mechanical stress.[1]

Commercially, buyers consider:

- Local availability and lead times via Saudi or regional distributors for TFT display products, which can significantly affect project schedules.

- Technical support, including design‑in assistance, interface guidance, firmware examples, and documentation for the selected TFT LCD or touch‑TFT display modules.[1]

Collaboration between overseas TFT display factories and Saudi integrators allows end users to receive localized after‑sales service, installation support, and troubleshooting, while still benefiting from advanced international display technology. This hybrid model reduces risk for project owners and ensures stable supply for long‑running industrial and infrastructure projects.[1]

For overseas TFT display manufacturers—including TFT LCD module factories, touch‑panel makers, and complete HMI device vendors—Saudi Arabia offers attractive cooperation opportunities.[1]

Promising cooperation models include:

- Partnering with Saudi automation distributors to bundle TFT display HMIs with PLCs, drives, sensors, and industrial PCs for turnkey production line upgrades.

- Working with Saudi panel builders and system integrators that design custom enclosures and cabinets, then embed imported TFT display modules into finished systems for industrial and building‑management projects.[1]

By offering custom TFT display assemblies (for example, combining TFT LCD panels with capacitive touch, anti‑glare or anti‑reflective coatings, and tailored mechanical frames), manufacturers can better address the environmental and functional needs of Saudi installations. Long‑term cooperation with local partners also helps ensure spare‑parts availability and consistent TFT display performance over multi‑year project lifecycles.[2]

To secure reliable TFT display solutions for projects in Saudi Arabia, buyers can consider a mixed sourcing strategy.[1]

First, local or regional distributors can supply branded industrial HMIs that already integrate high‑quality TFT LCD displays for standard automation tasks, such as pump control panels or packaging machine interfaces. These devices minimize engineering effort and allow fast deployment because housing, electronics, and software tools are already mature.[1]

Second, for customized or high‑volume equipment, OEMs can cooperate with TFT display specialists and overseas manufacturers to select appropriate TFT LCD modules and integrate them into bespoke panels or devices. This path offers greater control over appearance, ergonomics, and functionality, allowing manufacturers to differentiate their machines and systems with tailored TFT displays.[2]

In both cases, long‑term success depends on:

- Confirming product roadmaps and lifecycle guarantees for key TFT display models used in critical equipment.

- Maintaining relationships with both local distributors and original TFT display manufacturers to handle redesigns, upgrades, or replacements in future phases.[1]

Although individual projects vary, some typical examples help illustrate how TFT display technology is deployed across the Kingdom.[1]

One example is a water treatment plant that uses large industrial touchscreen displays with TFT LCD panels in its central control room, giving operators real‑time visualization of pumps, tanks, and valves on bright and detailed TFT displays. Engineers can zoom into specific process sections, acknowledge alarms, and switch between trends and mimic diagrams directly on the TFT display surface.[2]

Another example is a retail chain that installs TFT display‑based HMI devices for back‑office automation and TFT LCD digital signage screens in stores to communicate promotions, pricing, and branding. Here, both rugged small TFT displays and eye‑catching large TFT display panels are required to cover operational and marketing needs within one networked system.[1]

In transportation, passenger information screens on buses and trains use TFT LCD panels to show routes, stops, and announcements in Arabic and English, improving user experience and accessibility. Control rooms for traffic and logistics may rely on multi‑screen TFT display walls that combine data from sensors, cameras, and control systems to support fast decision‑making.[1]

For marketers and technical sales teams promoting TFT display solutions into Saudi Arabia, well‑designed content can significantly support lead generation and customer education.[1]

Effective ideas include:

- Case studies describing how a specific plant or building deployed TFT display‑based HMIs and achieved measurable improvements in uptime, safety, or energy efficiency.

- Technical white papers explaining how to select TFT LCD parameters—such as brightness, interface type, and touch technology—for Saudi environmental conditions, illustrated with diagrams and UI screenshots from real TFT displays.[1]

Short explainer videos can cover:

- The internal structure of a TFT display, showing the TFT matrix, backlight, polarizers, and color filters.

- The step‑by‑step process of integrating a TFT LCD module into a machine panel, including mounting, sealing, wiring, and software configuration.[1]

Such content helps potential buyers understand why a well‑specified TFT display is essential for long‑term project success and why cooperation with experienced TFT display partners—both local and international—is critical.[1]

Saudi Arabia's rapid industrialization and smart‑city agenda have made TFT display technology an essential component across factories, energy, retail, and transportation. While the Kingdom imports most TFT display hardware, a strong network of distributors, system integrators, and solution providers connects international TFT display manufacturers with local projects, ensuring that end users receive reliable TFT LCD solutions tailored to Saudi conditions.[1]

By leveraging global suppliers of custom TFT display modules and industrial TFT display systems, Saudi companies can deploy high‑performance visualization interfaces that improve safety, efficiency, and user experience. Careful partner selection, attention to lifecycle support, and the strategic use of both standard HMIs and custom TFT displays help ensure that new projects remain maintainable and future‑proof as technology and market requirements evolve.[2][1]

A TFT display is a thin‑film transistor flat‑panel display in which each pixel is driven by its own transistor, allowing sharper images, faster response, and better contrast than passive‑matrix displays. In industrial and commercial settings, TFT LCD displays are used in HMIs, monitors, digital signage, and embedded devices where clarity, durability, and long operating life are required.[2][1]

TFT display technology provides clear visualization and reliable operation even in demanding industrial environments, enabling operators to monitor processes accurately and respond quickly to alarms. Industrial TFT LCD panels used in Saudi Arabia typically feature high brightness, robust construction, and support for continuous 24/7 operation, which are critical for oil, gas, energy, and water applications.[1]

Most Saudi companies purchase TFT display solutions through local automation distributors, electronics retailers, and regional display specialists that represent global brands and stock key models. For custom equipment, they often work with overseas TFT LCD manufacturers or display module factories while using Saudi integrators to design panels, enclosures, and software around the TFT display hardware.[2][1]

Buyers should review the technical specifications of the TFT display—such as brightness, resolution, viewing angle, operating temperature, and expected lifetime—relative to local environmental conditions. They should also ensure long‑term availability, technical support, and convenient logistics via reliable distributors or system integrators serving Saudi Arabia.[1]

Yes, many overseas TFT LCD and TFT display manufacturers support Saudi customers through regional distributors, dedicated sales channels, and close cooperation with local integrators. By offering customized TFT display modules, detailed documentation, and long‑term product roadmaps, these manufacturers help Saudi clients implement stable, scalable visualization solutions in industrial and commercial projects.[2][1]

[1](https://www.perplexity.ai/search/7696108b-22e2-4a6b-9cd3-9b402b3fe7b4)

[2](https://www.perplexity.ai/search/bd58c367-7bfc-44a9-9b7d-e302fc7b0f18)