Views: 222 Author: Wendy Publish Time: 2025-12-22 Origin: Site

Content Menu

● Why Portugal for Resistive Touch Screen Projects?

● Overview of Resistive Touch Screen Technology

● Portugal's Touch and Display Ecosystem

● Key Players Relevant to Resistive Touch Screen Solutions

>> Example ecosystem participants

● Typical Applications of Resistive Touch Screen in Portugal

● How Portuguese Integrators Work with Resistive Touch Screen Hardware

● Comparing Resistive and Capacitive Touch for Portugal Projects

>> Touch technology options for Portuguese HMIs

● Working with Global Resistive Touch Screen Manufacturers

● Practical Sourcing Tips for Resistive Touch Screen Buyers in Portugal

● Example Content Ideas for Images and Videos

● Lifecycle, Maintenance, and Reliability of Resistive Touch Screen Systems

● How a Chinese Abrasive and Refractory Supplier Fits into This Value Chain

● FAQ

>> 1. What is a Resistive Touch Screen and how does it work?

>> 2. Why choose a Resistive Touch Screen for industrial projects in Portugal?

>> 3. Can Portuguese companies supply both resistive and capacitive touch solutions?

>> 4. How do overseas buyers usually cooperate with Portuguese integrators?

>> 5. Are Resistive Touch Screen solutions still competitive against modern capacitive technologies?

Portugal is an increasingly attractive destination for sourcing industrial displays, HMI panels, and integrated systems that can be combined with Resistive Touch Screen technology for demanding European projects. For global OEMs, system integrators, and distributors, cooperating with Portuguese display and HMI specialists offers a balance of EU‑level quality, flexible customization, and competitive total cost of ownership when using Resistive Touch Screen solutions.[1][2] For international buyers sourcing from Resistive Touch Screen manufacturers and suppliers, understanding the local producers, product ranges, and quality standards is the key to successful cooperation.

Portugal plays a strong role in Europe's display and touch ecosystem mainly as a system integration and engineering hub rather than a mass producer of raw Resistive Touch Screen sensors. Local companies typically import LCD and touch modules (including Resistive Touch Screen and capacitive) and then engineer complete, application‑ready terminals and panel PCs.[1]

- Portuguese integrators combine displays, Resistive Touch Screen sensors, embedded computers, enclosures, and software into turnkey solutions for industrial, transport, retail, and public sectors.[2][1]

- For international buyers, Portugal offers EU compliance, familiarity with CE, EMC, and safety standards, and convenient access to Western Europe for after‑sales support of Resistive Touch Screen systems.[2][1]

To maximize project success, many buyers combine Asian Resistive Touch Screen manufacturing with Portuguese engineering to achieve cost‑effective yet robust and certified systems ready for European deployment.[1]

A Resistive Touch Screen uses pressure to detect touch by measuring changes in resistance between conductive layers, which makes it fundamentally different from capacitive touch that senses changes in an electric field. This pressure‑based operation allows Resistive Touch Screen panels to work reliably with gloves, stylus pens, and in environments where users may have wet or dirty hands.[3][4]

- Typical industrial Resistive Touch Screen solutions are available in 4‑wire, 5‑wire, and analog resistive structures that can be integrated with many LCD sizes.[5][3]

- In HMIs, resistive or capacitive options are often both available; when the environment is harsh, contaminated, or requires precise stylus input, a Resistive Touch Screen remains a practical choice.[4][3]

For OEMs and industrial buyers, understanding the strengths of a Resistive Touch Screen—ruggedness, input flexibility, and predictable behavior—is essential when designing long‑lifecycle equipment.

Even though Portugal is best known for capacitive and interactive display solutions, much of the same ecosystem also supports projects based on Resistive Touch Screen technology when customers request it. System integrators source resistive sensors from global partners and embed them into kiosks, industrial HMIs, and customized terminals designed and assembled in Portugal.[6][2][1]

- Local providers design mechanical structures, IP‑rated housings, and mounting systems while selecting the appropriate Resistive Touch Screen or capacitive module depending on the environment.[2][1]

- Many projects follow a hybrid model: resistive or capacitive panels from Asian manufacturers combined with Portuguese design, assembly, and software integration to meet specific sector standards.[1][2]

This model allows buyers to leverage low‑cost Resistive Touch Screen hardware with high‑value Portuguese engineering and local support.

While some well‑known companies around Portugal focus primarily on PCAP and LED/LCD systems, their capabilities, integration skills, and product portfolios are directly relevant to customers who need Resistive Touch Screen‑based systems.[6][2][1]

- DISPLAX (Braga region) – A world‑leading manufacturer of projected capacitive touchscreens; its engineering experience, controller technology, and global network often intersect with projects that also require Resistive Touch Screen solutions or mixed fleets of devices in one project.[6][1]

- Digital signage and interactive display firms in Portugal – Specialists in LCD and LED display systems that include interactive touchscreen options; they work with various technologies and can design enclosures and electronics around customer‑selected touch modules, including Resistive Touch Screen sensors when required.[2]

Alongside these, multiple LED and LCD display solution providers in Portugal supply complete display walls, kiosks, and interactive windows, and often collaborate with overseas touch panel factories for resistive and other touch modules.[2]

Resistive Touch Screen HMIs and terminals are widely used in sectors where robust, glove‑friendly, and precise input is essential. In Portugal and across Europe, these solutions are often integrated into larger systems that must withstand harsh use and environmental challenges.[3][4][1][2]

Common application fields include:

- Industrial automation and machinery: Panel PCs and operator terminals using a Resistive Touch Screen in factories, food processing lines, and energy plants.[7][4]

- Transportation, ticketing, and kiosks: Ticket machines, parking meters, and information kiosks that must function outdoors or in semi‑outdoor environments where a Resistive Touch Screen offers stable performance and stylus compatibility.[8][2]

- Medical and laboratory equipment: Devices that require accurate stylus input and compatibility with gloves and disinfectants often still rely on Resistive Touch Screen interfaces.[4][3]

By combining a properly sealed enclosure, industrial electronics, and a Resistive Touch Screen, Portuguese integrators can deliver long‑lifecycle HMI platforms for demanding projects.[4][1]

Most Portuguese companies do not fabricate raw Resistive Touch Screen glass sensors locally; instead, they select suitable modules from international manufacturers and integrate them into complete systems. This approach allows them to offer a wide range of Resistive Touch Screen sizes, aspect ratios, and controller types while focusing on mechanical and software engineering.[5][1][2]

- Hardware selection: Engineers choose from standard and custom Resistive Touch Screen sizes (such as 3.5″, 7″, 10.1″, and larger industrial formats) offered by global suppliers in Europe and Asia.[9][5]

- System design: Portuguese integrators design housings, backlights, optical bonding, and controller boards to optimize image quality and touch accuracy for each Resistive Touch Screen panel.[4][1]

- Certification and compliance: Local partners manage CE, EMC, and safety certification for the final product so that the Resistive Touch Screen system is ready for deployment in EU markets.[1][2]

For buyers, this means a single point of contact for the whole system—display, Resistive Touch Screen, embedded PC, software image, and mechanical design.

When sourcing HMIs and industrial displays in Portugal, project owners often compare Resistive Touch Screen and capacitive technology to find the best match for their environment. The table below highlights core differences that matter when working with Portuguese manufacturers and integrators.[3][4]

| Aspect | Resistive Touch Screen | Capacitive Touch (PCAP) |

|---|---|---|

| Input method | Pressure; works with glove, stylus, or any object. | Conductive touch; typically bare finger or special glove. |

| Rugged environments | Very suitable for dirty, wet, or high‑EMI environments where simple, sealed HMIs are needed. | Excellent for clean indoor environments and premium interactive signage. |

| Precision | High precision with stylus on small UI elements. | Good for gestures but less ideal for very small on‑screen targets. |

| Optical clarity | Usually slightly lower clarity because of multiple layers, but can be improved with optical bonding. | Typically higher transparency and better visual performance for media‑rich interfaces. |

| Cost | Often lower cost for small and mid‑size panels, especially from Asian suppliers. | May be higher cost, particularly in larger sizes and advanced PCAP sensors. |

Portuguese integrators can advise whether a Resistive Touch Screen or capacitive solution is better for each application and can mix both technologies within a product portfolio.[4][1]

Because Portugal focuses on integration, many projects source the core Resistive Touch Screen hardware from specialized global manufacturers, then complete the mechanical and system integration locally. This approach gives buyers access to advanced Resistive Touch Screen designs while keeping European engineering and support close to the deployment site.[9][5][1]

Typical global partners that supply resistive sensors and touch modules include:

- Resistive sensor manufacturers offering analog resistive and 4‑wire/5‑wire Resistive Touch Screen sensors for industrial and commercial use.[10][5]

- Custom touch display manufacturers that can provide fully bonded LCD + Resistive Touch Screen assemblies tailored to OEM specifications.[11][9]

By working with Portuguese system houses, overseas buyers can request that these global Resistive Touch Screen modules be integrated into IP‑rated, EMC‑tested, and software‑configured systems adapted to the target application.[1][2]

Several practical steps can help global OEMs and project owners source the right Resistive Touch Screen solutions through Portuguese partners.[2][1]

- Define environment and usage: Clearly describe installation conditions—temperature range, humidity, vibration, chemical exposure, and glove use—so the integrator can confirm whether a Resistive Touch Screen is the best choice.[7][4]

- Specify performance targets: Resolution, brightness, touch lifespan, and expected daily usage should all be defined so that the Resistive Touch Screen and LCD combination meets lifecycle requirements.[5][9]

- Confirm regulatory needs: Discuss CE, EN, and industry‑specific standards that your Resistive Touch Screen system must meet, such as railway, medical, or marine certifications.[1][2]

- Consider hybrid strategies: For large fleets, buyers can standardize around a Resistive Touch Screen HMI platform for tough environments while using capacitive solutions for premium or indoor kiosks—both supported by Portuguese integrators.[6][1]

A clear requirements document and early technical workshops with the supplier help ensure that the chosen Resistive Touch Screen architecture matches long‑term project goals.

To make a marketing article or landing page more engaging, content creators can insert relevant images and videos around the theme of Resistive Touch Screen sourcing in Portugal.[2][1]

Suggested image topics:

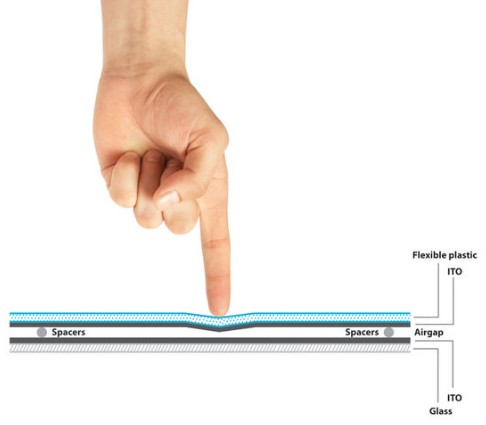

- Cross‑section diagrams showing the conductive layers inside a Resistive Touch Screen and how pressure changes resistance.

- Photos of industrial HMIs and panel PCs installed on production lines, using Resistive Touch Screen fronts with physical emergency‑stop buttons beside them.

- Pictures comparing user interaction on a Resistive Touch Screen with gloves versus a capacitive panel requiring bare fingers.

Suggested video topics:

- A demonstration video of operators using a Resistive Touch Screen panel in a factory, highlighting stability under vibration and electrical noise.

- A short clip from an integration workshop in Portugal, showing mounting of a Resistive Touch Screen module into an IP‑rated enclosure and performing calibration.

- Customer interviews explaining why they chose a Resistive Touch Screen system instead of a fully capacitive HMI for harsh sites.

These visuals help potential buyers quickly understand the functional benefits and real‑world performance of each Resistive Touch Screen solution.[4][1]

When selecting a Resistive Touch Screen platform, lifecycle and maintainability are just as important as initial purchase price. Portuguese integrators can design systems so that key components, such as the LCD and Resistive Touch Screen overlay, are serviceable without replacing the entire HMI.[7][4][1][2]

Key lifecycle considerations:

- Durability of overlays: Industrial‑grade Resistive Touch Screen overlays are specified for hundreds of thousands or even millions of actuations, which is suitable for panel PCs used in shift operations.[3][5]

- Calibration and drift: Modern Resistive Touch Screen controllers reduce drift and offer simple calibration utilities so that users can keep cursor accuracy within tight tolerances over years of use.[5][3]

- Spare parts strategies: By standardizing on certain Resistive Touch Screen sizes and controller families, buyers can simplify spare parts management and reduce downtime.[1][2]

In many industries, the combination of predictable behavior, straightforward maintenance, and robust mechanical design keeps Resistive Touch Screen HMIs in operation well beyond their initial warranty period.[7][4]

For global industrial customers, sourcing is rarely limited to one category; they may need both rugged HMIs with Resistive Touch Screen interfaces and high‑performance abrasives and refractories for equipment and plant maintenance. A Chinese company specializing in abrasives and refractory materials can cooperate with Portuguese HMI integrators to offer combined solutions for OEMs, integrators, and end users in heavy industry.[1]

- Joint projects can include machine tools, grinding systems, furnaces, and kilns that rely on Resistive Touch Screen HMIs for control and on abrasives or refractories for core process stability.

- Overseas buyers benefit from a unified technical discussion covering both the Resistive Touch Screen control surface and the high‑temperature or high‑wear components in the same industrial line.[4]

Positioning your abrasive and refractory products alongside advanced Resistive Touch Screen HMIs highlights your ability to support the entire lifecycle of industrial equipment.

Portugal is an important hub for the integration and deployment of industrial HMIs, kiosks, and display systems that can rely on Resistive Touch Screen technology for rugged and glove‑friendly operation. Local companies specialize in system design, enclosure engineering, lifecycle planning, and regulatory compliance, while global touch manufacturers supply the Resistive Touch Screen sensors and LCD modules themselves.[5][4][1]

For international buyers, this ecosystem offers a compelling combination: cost‑effective Resistive Touch Screen hardware from global factories integrated into robust, fully certified solutions by Portuguese partners ready for deployment across Europe. When combined with high‑quality industrial materials such as abrasives and refractories, these Resistive Touch Screen systems help create reliable, long‑life equipment for demanding industrial applications.[4][2][1]

A Resistive Touch Screen uses two or more thin conductive layers separated by a small gap; when pressure is applied, the layers make contact and the controller calculates the touch position from changes in resistance. Because it is pressure‑sensitive, a Resistive Touch Screen works with fingers, gloves, stylus pens, and many other objects in industrial and outdoor environments.[3][5][4]

Industrial projects in Portugal often involve factories, logistics centers, and transport systems where operators wear gloves or work in dusty or wet environments, making a Resistive Touch Screen ideal. Portuguese integrators can package Resistive Touch Screen panels in IP‑rated enclosures with industrial PCs, ensuring long lifecycles and compliance with European standards.[7][3][4][1]

Yes, most display and HMI specialists in Portugal can work with both Resistive Touch Screen and capacitive technologies, selecting the best option for each application. This allows buyers to standardize rugged systems on Resistive Touch Screen interfaces while using PCAP for premium, gesture‑rich or indoor interfaces in the same product family.[6][4][1]

Overseas buyers typically provide project specifications—screen size, environment, interfaces, and certifications—while Portuguese integrators design the mechanical structure and select suitable Resistive Touch Screen or capacitive modules from global suppliers. The integrator then assembles, tests, and certifies the finished HMI so that the buyer receives a turnkey, deployment‑ready system.[4][2][1]

Resistive Touch Screen solutions remain very competitive in harsh or specialized environments where glove operation, stylus precision, and predictable behavior are more important than multi‑touch gestures or glass‑to‑edge aesthetics. When combined with modern optical bonding, controllers, and robust enclosures designed by Portuguese integrators, a Resistive Touch Screen can provide excellent durability and total cost of ownership over long equipment lifecycles.[3][5][4][1]

[1](https://www.reshine-display.com/top-capacitive-touch-screen-manufacturers-and-suppliers-in-portugal.html)

[2](https://nseledcloud.com/led-display-portugal/)

[3](https://gett-group.com/en/gettechnology/technology-expertise/low-touch-technologies)

[4](https://www.esa-automation.com/en/6-fundamental-features-in-a-panel-pc-2/)

[5](https://crystal-display.com/products/analogue-resistive-touch/)

[6](https://www.displax.com)

[7](https://gett-asia.com/panel-pc)

[8](https://automa.net/category/hmi-panels-6627c3e550995b451986f06b)

[9](https://newhavendisplay.com/de/custom-solutions/custom-touchscreen-display-solutions/)

[10](https://www.rxtplcd.com/resistance-touch-screen-1-5-inche/)

[11](https://touchscreenmfg.com/touch-screen/)

Top Resistive Touch Screen Manufacturers and Suppliers in Turkey

Top Resistive Touch Screen Manufacturers and Suppliers in Vietnam

Top Resistive Touch Screen Manufacturers and Suppliers in South Korea

Top Resistive Touch Screen Manufacturers and Suppliers in Japan

Top Resistive Touch Screen Manufacturers and Suppliers in Italy

Top Resistive Touch Screen Manufacturers and Suppliers in Portugal

Top Resistive Touch Screen Manufacturers and Suppliers in Spain