Views: 222 Author: Wendy Publish Time: 2025-12-22 Origin: Site

Content Menu

● Market Background for Resistive Touch Screen Solutions in Spain

● Core Features of Industrial Resistive Touch Screen Solutions

● Representative Resistive Touch Screen Players Serving Spain

>> MATRIX Electrónica – Local Resistive Touch Panels

>> Irontech Group – Industrial Touch Screen Monitors and Panel PCs

>> Other HMI Touch Panel Manufacturers Active in Spain

● European and Global Resistive Touch Screen Partners Supporting Spain

● Typical Applications of Resistive Touch Screen Solutions in Spain

● How to Select a Resistive Touch Screen Supplier in Spain

● Integration Considerations for Resistive Touch Screen HMIs

● How Chinese Manufacturers Cooperate with Spanish Resistive Touch Screen Projects

● How a Chinese Abrasives and Refractories Supplier Fits into This Ecosystem

● FAQ – Resistive Touch Screen in Spain

>> 1. What is a Resistive Touch Screen and why is it popular in Spain?

>> 2. Which industries in Spain most often use Resistive Touch Screen HMIs?

>> 3. How do Spanish suppliers customize Resistive Touch Screen solutions?

Spain is an important market for industrial HMI, kiosks, medical devices, and transport systems that still rely heavily on Resistive Touch Screen solutions because of their robustness and predictable performance in harsh environments. For global OEMs and system integrators, understanding the local ecosystem of Resistive Touch Screen manufacturers and suppliers in Spain helps optimize sourcing, customization, and lifecycle support.[1][2][3]

Resistive Touch Screen technology remains widely used in Spain in sectors where reliability and glove or stylus operation are more critical than multi‑touch gestures. Industrial plants, logistics hubs, and public infrastructure projects often favor Resistive Touch Screen panels for their resistance to dust, moisture, and electromagnetic noise.[2][1]

Key reasons Spanish buyers still choose Resistive Touch Screen solutions include:[3][1]

- Operation with gloves, pens, or any object, ideal for factories, food processing, and outdoor maintenance

- Stable performance in environments with oil, dust, humidity, or cleaning chemicals

- Competitive cost, especially for medium‑size HMI terminals and control panels

- Mature supply chain with standard sizes and long‑term availability from global partners

In Spain, the shift toward capacitive touch in consumer devices has not eliminated the strong base of Resistive Touch Screen installations in industrial and semi‑public environments. Many modernization projects still maintain resistive interfaces to keep operating procedures stable, protect investments, and ensure compatibility with existing enclosures and tools.[1][2][3]

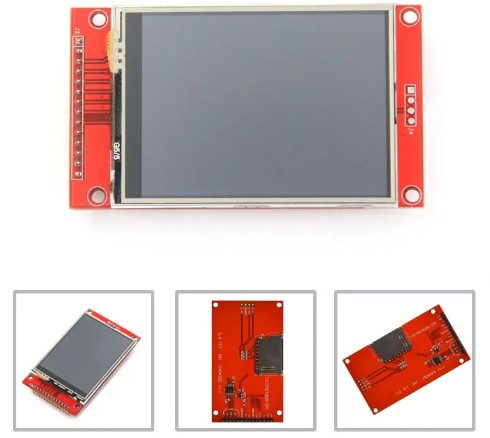

Industrial buyers in Spain look for a combination of optical quality, durability, and integration flexibility when specifying a Resistive Touch Screen. A typical industrial Resistive Touch Screen stack combines a glass or film‑glass sensor, protective cover, controller board, and mounting frame.[4][2][1]

Important technical characteristics include:[4][1]

- High transparency and low reflection to maintain LCD readability behind the Resistive Touch Screen

- 4‑wire or 5‑wire technology options, with 5‑wire often preferred for long‑life industrial HMI use

- Wide operating temperature, supporting installation in cold rooms, outdoor enclosures, and hot production lines

- Chemical resistance of the front surface, allowing frequent cleaning and disinfection

Engineers in Spain often compare different Resistive Touch Screen options based on touch linearity, activation force, and long‑term drift. Project teams balance the higher robustness of 5‑wire resistive sensors against cost and availability, while also checking controller compatibility with their preferred industrial PCs or PLCs.[1][4]

The Resistive Touch Screen market in Spain is supported by a mix of local specialists, Europe‑wide distributors, and global technology brands that provide sensors, touch monitors, and integrated panel PCs.[2][1]

MATRIX Electrónica, headquartered in Spain, offers a range of Resistive Touch Panels that focus on high transparency, low reflection, and industrial‑grade quality standards. Its portfolio covers 4‑wire and 5‑wire resistive panels in multiple sizes, making it a key local resource for OEMs needing customized Resistive Touch Screen front‑ends.[1]

Typical applications in Spain include:[1]

- Industrial controllers and PLC operator panels

- Embedded displays for transportation and public ticketing machines

- Medical and laboratory devices where glove operation is critical

MATRIX supports projects with detailed datasheets, mounting drawings, and technical guidance so that engineers can select the most suitable Resistive Touch Screen format. Spanish customers value the combination of local communication, flexible logistics, and access to international resistive sensor technologies through this channel.[3][1]

Irontech Group designs and manufactures industrial touch screen monitors and panel PCs made in Spain, many of which can be specified with Resistive Touch Screen options for harsh environments. The company focuses on rugged stainless‑steel housings, IP66 front protection, and full wash‑down capability for industries such as food processing and chemicals.[5][2]

Key characteristics of Irontech's industrial touch solutions include:[5][2]

- Wide range of monitor sizes with industrial brightness and resolution

- Front IP66 protection and fully sealed stainless‑steel VESA enclosures

- Customizable touch options (resistive or capacitive) depending on the HMI requirement

For Spanish food, beverage, and pharmaceutical plants, Resistive Touch Screen front panels from Irontech are often combined with high‑pressure cleaning routines and aggressive detergents. The ability to operate through thick gloves while maintaining sealing and hygiene standards is a major driver for continued resistive adoption in these sectors.[2][5]

Industry articles on HMI touch panel manufacturers in Spain highlight several brands with strong expertise in rugged touch systems, offering resistive, projected capacitive, and hybrid configurations. These manufacturers position their HMI touch panels for industrial automation, digital signage, and other demanding applications, often with Resistive Touch Screen configurations for specific customer needs.[3]

Across these Spanish players, common strengths include:[2][3]

- Ability to adapt HMI mechanics to existing machine cut‑outs and cabinets

- Know‑how in selecting the right touch technology (resistive versus capacitive) per project

- Support for EU certifications and documentation, simplifying audits and approvals

Because many projects combine local hardware with software from global automation vendors, Spanish HMI manufacturers ensure that their Resistive Touch Screen solutions are compatible with major SCADA and PLC platforms. This compatibility reduces commissioning risks and helps OEMs standardize on a single HMI hardware family across multiple plants.[5][3][2]

Spain's Resistive Touch Screen market is also supplied by Europe‑wide and global brands that provide standardized resistive sensors, touch kits, and integrated displays, often through distributors and local engineering partners. These partners allow Spanish companies to source a wide variety of Resistive Touch Screen sizes and controller combinations without maintaining large inventories themselves.[6][4]

Notable aspects of these partnerships include:[6][4]

- Availability of analogue Resistive Touch screens from established sensor brands aimed at low‑cost industrial applications

- Large catalogs of resistive touch panels with anti‑reflective coatings and different tail, connector, and controller options

- Design‑in support for custom cover‑lens printing, logo integration, and mechanical adaptations

Some global suppliers also work closely with Spanish distributors to pre‑certify certain Resistive Touch Screen modules for use in ATEX or other regulated environments. This pre‑certification reduces time‑to‑market when Spanish OEMs design new HMIs for hazardous or safety‑critical installations.[4][6][2]

Resistive Touch Screen technology is deployed across a broad range of Spanish industries where touch reliability under harsh conditions outweighs the need for multi‑touch gestures. Common application areas include:[3][2][1]

- Industrial automation: PLC operator panels, control cabinets, and SCADA terminals in metallurgy, automotive, packaging, and logistics plants

- Food and pharmaceutical: Stainless‑steel HMI terminals with IP‑rated enclosures, cleaned frequently with aggressive agents

- Transportation: Ticketing machines, driver interfaces, and passenger information systems that must work with gloves and under sunlight

- Medical and laboratory: Devices requiring stylus or pen input and frequent disinfection, where Resistive Touch Screen surfaces are advantageous

Spanish integrators often retrofit older machines by replacing membrane keypads with Resistive Touch Screen HMIs while keeping existing control logic intact. This strategy offers operators a more modern interface without the cost and risk of replacing entire automation systems.[2][3][1]

Choosing the right Resistive Touch Screen supplier in Spain requires evaluating technical capabilities, customization options, and support services. Buyers should align project requirements with what each manufacturer or distributor can deliver in terms of sensor technology, mechanical integration, and lifecycle management.[3][1][2]

Key selection criteria for Resistive Touch Screen manufacturers and suppliers include:[4][1]

- Technology and size range

- Support for 4‑wire and 5‑wire resistive sensors

- Panel sizes matching intended LCD formats (e.g., 7", 10.4", 12.1", and larger industrial formats)

- Optical and mechanical performance

- Transparency and anti‑reflection levels suitable for indoor or outdoor use

- Surface hardness and resistance to scratching or chemical cleaning

- Mounting options: bezel‑mount, frame‑mount, or full panel PC with Resistive Touch Screen

- Environmental and regulatory compliance

- Operating temperature range and IP protection for industrial or food‑grade environments

- Certifications relevant to target industries

- Engineering and lifecycle support

- Availability of CAD drawings, 3D models, wiring diagrams, and firmware guides

- Clear last‑time‑buy notices and long‑term support plans for Resistive Touch Screen models

Spanish OEMs commonly run pilot installations to test touch performance, optical clarity, and durability before committing to volume orders. Feedback from operators and maintenance teams is then used to refine HMI size, brightness, and Resistive Touch Screen configuration for full roll‑out.[1][2][3]

Integrating a Resistive Touch Screen into an industrial or semi‑public system requires careful attention to mechanical design, EMC behavior, and user ergonomics. Engineering teams must harmonize the Resistive Touch Screen module, LCD, and enclosure to ensure long‑term reliability.[4][2][1]

Important integration aspects include:[4][1]

- Mechanical: Correct gasket compression, even mounting pressure, and robust cable routing to prevent tail damage

- Electrical: Proper grounding and shielding of Resistive Touch Screen controllers to minimize noise and ghost touches

- Software: Calibration routines, touch‑area scaling, and UI design optimized for single‑touch Resistive interactions

Spanish integrators often prefer standardized HMI footprints and cut‑out dimensions so that multiple generations of Resistive Touch Screen and display hardware can be swapped without redesigning cabinets. This approach simplifies maintenance and allows factories to migrate gradually to improved touch modules while keeping overall machine design stable.[2][1][4]

For Spanish OEMs, distributors, and system integrators, partnering with experienced Chinese manufacturers can reduce costs and expand the range of available Resistive Touch Screen sizes and specifications. Chinese factories supply touch sensors, open‑frame monitors, and industrial panel PCs that can be combined with local Spanish engineering and after‑sales support.[7][8]

A typical cooperation model involves:[8][7]

- Chinese manufacturers providing custom Resistive Touch Screen sensors or integrated touch monitors with options for cover glass printing, controller selection, and interface customization

- Spanish partners handling system design, mechanical housings, certification, logistics, and local service to meet EU expectations

- Joint marketing using case studies and visual documentation to show completed installations of Resistive Touch Screen HMIs in Spanish factories and public spaces

This hybrid approach allows Spanish end users to benefit from competitive global manufacturing while preserving proximity, language, and on‑site support through local touch‑screen specialists. It also gives Chinese manufacturers deeper access to EU application know‑how, helping them optimize future Resistive Touch Screen product lines.[7][8]

As a Chinese company specialized in high‑quality abrasives and refractory materials, supplying the global abrasives and grinding industry, there is a natural connection with rugged HMI and Resistive Touch Screen applications. Many grinding, cutting, and thermal‑processing lines require durable control panels and touch interfaces that withstand abrasive dust, high temperatures, and frequent cleaning.[5][2]

By collaborating with Spanish Resistive Touch Screen manufacturers and integrators, such a supplier can:[5][2]

- Support OEMs in designing robust machine housings and HMI panels that resist mechanical wear, heat, and corrosion

- Provide refractory and protective materials used in enclosures around Resistive Touch Screen HMIs in furnaces, kilns, and high‑temperature production lines

- Develop technical case‑study content that shows grinding or refractory equipment together with integrated Resistive Touch Screen operator stations

This collaboration highlights how complete solutions—machines, materials, and Resistive Touch Screen HMIs—work together to increase safety, uptime, and process control in demanding industrial environments.[5][2]

Spain offers a mature but growing ecosystem for Resistive Touch Screen technology, led by local panel specialists, industrial monitor manufacturers, and Europe‑wide distributors that serve OEMs in automation, transportation, food processing, and medical sectors. By carefully selecting Resistive Touch Screen suppliers based on technology, environmental performance, documentation, and engineering support, buyers can secure long‑term, reliable HMI solutions tailored to Spanish and EU requirements. Combining Spanish engineering and after‑sales service with cost‑effective global manufacturing and rugged materials from Chinese partners enables robust, competitive Resistive Touch Screen projects for the global abrasives, grinding, and industrial markets.[8][7][1][2][4]

A Resistive Touch Screen is a pressure‑sensitive touch sensor made of multiple layers that register a touch when two conductive layers are pressed together. It remains popular in Spain because it works reliably with gloves, stylus, or any object, and is well suited to dusty, humid, or chemically cleaned industrial environments.[1][2][4]

In Spain, Resistive Touch Screen HMIs are widely used in industrial automation, food and pharmaceutical production, transportation ticketing and information systems, and medical or laboratory equipment. These sectors value single‑touch reliability, ease of cleaning, and compatibility with protective gloves and stylus input.[3][2][1]

Spanish suppliers and their European partners customize Resistive Touch Screen solutions by offering different sensor sizes, 4‑wire or 5‑wire technologies, cover‑glass designs, and mounting options tailored to each project. They also provide engineering support, drawings, and integration guidance so OEMs can combine the Resistive Touch Screen with LCDs, controllers, and cabinets efficiently.[2][4][1]

Sourcing from Spain plus global partners combines local engineering, certifications, and after‑sales service with competitive worldwide manufacturing and a broad component catalog. This gives OEMs access to high‑quality Resistive Touch Screen sensors and industrial monitors while keeping logistics, communication, and technical support close to their end markets.[7][8][2]

A Chinese industrial materials supplier can collaborate with Spanish Resistive Touch Screen manufacturers by providing rugged housings, refractory components, and protective materials used around HMIs in high‑temperature or abrasive environments. Joint projects and case‑study content can show how robust mechanical design and Resistive Touch Screen interfaces work together to improve reliability and safety in grinding and thermal‑processing lines.[5][2]

[1](https://www.matrix.es/en/product/other-products/displays-en/resistive-touch-panels)

[2](https://irontech-group.com/en/industrial-monitor/)

[3](https://www.jshyst.com/blog/top3hmi-touch-panelmanufacturersinspain)

[4](https://unisystem.com/catalog/touch-screens/touch-screens-resistive)

[5](https://irontech-group.com/en/industrial-panel-pc/)

[6](https://crystal-display.com/products/analogue-resistive-touch/)

[7](https://baobaotechnology.com/our-product/10-4-inch-capacitive-touch-screen-monitor/)

[8](https://www.winstar.com.tw/location/distributors/europe/spain.html)

Top Resistive Touch Screen Manufacturers and Suppliers in Turkey

Top Resistive Touch Screen Manufacturers and Suppliers in Vietnam

Top Resistive Touch Screen Manufacturers and Suppliers in South Korea

Top Resistive Touch Screen Manufacturers and Suppliers in Japan

Top Resistive Touch Screen Manufacturers and Suppliers in Italy

Top Resistive Touch Screen Manufacturers and Suppliers in Portugal

Top Resistive Touch Screen Manufacturers and Suppliers in Spain