Views: 222 Author: Wendy Publish Time: 2025-12-25 Origin: Site

Content Menu

● What Is a Resistive Touch Screen?

● South Korea's Touch Screen and HMI Ecosystem

● Key South Korean Resistive Touch Screen Manufacturers and Suppliers

>> Alpha Display Co., Ltd. (ALPHADISPLAY)

>> Inotouch Technology Co., Ltd.

>> TLVision

>> Hantouch and Other Industrial Touch Providers

● Main Application Fields for Resistive Touch Screen Solutions

>> Industrial Automation and Panel PCs

>> Kiosks, Ticketing Machines, and Public Terminals

>> Medical Devices and Laboratory Equipment

● Technical Considerations When Selecting a Resistive Touch Screen

>> Controller Interface and EMC Performance

>> Lifetime, Durability, and Testing

● Project and Supply‑Chain Considerations

>> Communication and Engineering Support

>> Lead Times, MOQ, and Lifecycle Management

● FAQ About Resistive Touch Screen Sourcing in South Korea

>> What is the main benefit of using a Resistive Touch Screen instead of a capacitive panel?

>> Are South Korean suppliers suitable for long‑term industrial projects?

>> Can Korean companies customize mechanical design and branding for a Resistive Touch Screen?

>> How should an overseas buyer start a Resistive Touch Screen project with a Korean supplier?

>> Do Korean manufacturers support both four‑wire and five‑wire Resistive Touch Screen technologies?

South Korea has developed a strong ecosystem of display and touch‑interface companies supplying industrial monitors, HMI panels, and Resistive Touch Screen solutions to global OEMs and system integrators. For buyers who need stable operation in harsh environments, a South Korean Resistive Touch Screen manufacturers and suppliers can offer high quality, flexible customization, and competitive lead times.[1][2][3][4]

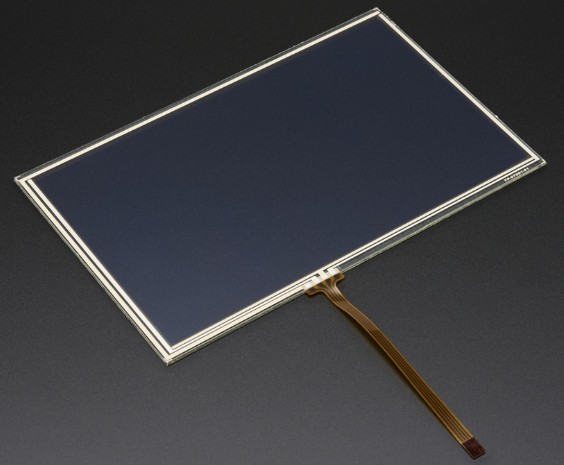

A Resistive Touch Screen is a pressure‑sensitive touch interface made from two transparent conductive layers separated by spacer dots. When a user presses the surface, the layers contact and the controller measures the resulting voltage change to determine the touch position. Because it reacts to pressure rather than skin capacitance, a Resistive Touch Screen works with fingers, stylus pens, and all kinds of gloves, even in dusty or oily environments.[4][5][6]

Compared with many capacitive solutions, a Resistive Touch Screen usually has simpler controllers, is easier to shield from electrical noise, and maintains predictable behavior under moisture and contamination. Although multi‑touch capability is limited, a Resistive Touch Screen remains a practical, cost‑effective choice for industrial automation, medical devices, kiosks, and transportation HMIs where reliable single‑touch input is more important than gesture control.[2][3][5][6]

South Korea's long history in semiconductors and flat‑panel displays naturally supports a strong industry around Resistive Touch Screen and capacitive touch technologies. Upstream suppliers handle glass processing, ITO coating, FPC design, and controller ICs, while downstream integrators assemble complete industrial monitors, panel PCs, and HMI terminals that incorporate a Resistive Touch Screen where required.[7][8][9][4]

Many Korean companies can supply both projected capacitive and Resistive Touch Screen modules, giving OEMs the flexibility to select the most suitable technology for each model in their product family. This ecosystem helps overseas buyers shorten development cycles, maintain stable quality, and obtain long‑term support for Resistive Touch Screen‑based equipment.[6][10][1][2]

Touch & Display is a specialist in industrial monitors, touch monitors, and industrial touch panel PCs, supplying global customers in automation, kiosks, transportation, and digital signage. The company offers various front‑panel technologies, including projected capacitive and Resistive Touch Screen options that can be customized for different mechanical designs and environmental requirements.[8][9][2][4]

For projects that need glove operation, stylus input, or stable single‑touch performance, Touch & Display can configure its panel PCs and open‑frame monitors with a Resistive Touch Screen and appropriate controller interface. Engineering teams support OEMs with interface matching, housing design advice, and test reports so that the chosen Resistive Touch Screen meets safety and EMC requirements in the final equipment.[6][7][8]

Alpha Display focuses on industrial‑grade monitors and touch solutions for gaming, industrial control, and transportation applications. Its portfolio covers multiple technologies such as surface capacitive, projected capacitive, infrared, and Resistive Touch Screen modules that can be paired with a wide range of LCD sizes.[9][7][8][6]

When end‑users operate equipment with gloves or stylus, Alpha Display can replace a capacitive front with a Resistive Touch Screen while keeping the same mechanical outline and display characteristics. The company also supports custom cover glass printing, mounting frames, and interface boards so that the complete Resistive Touch Screen assembly integrates smoothly into customer cabinets or kiosks.[2][4][8][9]

Inotouch Technology is known for its experience with four‑wire and five‑wire Resistive Touch Screen panels designed for kiosks, industrial machines, and general HMIs. Five‑wire Resistive Touch Screen technology places all measurement electrodes on a single layer, improving accuracy and durability, which is attractive for heavy‑duty industrial and medical devices.[5][4][6]

The company offers a variety of standard sizes and can develop custom Resistive Touch Screen designs that match special LCD formats or front‑panel cut‑outs. Overseas customers benefit from stable long‑term supply, increased lifetime in terms of actuation cycles, and flexible controller options such as USB and serial interfaces.[11][5][2]

TLVision is positioned as a touch panel technology company that works as a development and manufacturing partner for domestic and overseas IT and industrial customers. Its capabilities include R&D, prototyping, and mass production for a range of touch technologies, including Resistive Touch Screen solutions used in custom equipment and OEM devices.[10][8][6]

For projects where resistive technology is preferred, TLVision can tailor the Resistive Touch Screen structure, thickness, and surface treatment to meet shock, vibration, and optical requirements. Combined with firmware tuning and controller optimization, this allows OEMs to achieve stable, precise input even in noisy electrical environments.[3][7][10][6]

Hantouch is often cited as a source of industrial Resistive Touch Screen products ranging from small 5.7‑inch panels to larger formats used in automation and kiosk systems. Its analog Resistive Touch Screen modules are known for consistent performance, straightforward controller integration, and robust construction suitable for wide temperature operation.[4][5][2]

In addition, other Korean industrial PC and HMI brands integrate Resistive Touch Screen fronts into their panel PCs and controllers when glove or stylus operation is specified by the end customer. Together, these companies form a comprehensive supply base for both standalone Resistive Touch Screen components and complete HMI assemblies.[7][8][10][2]

In industrial environments such as factories, warehouses, and process plants, operators frequently wear gloves and may work in high‑noise, dusty, or oily conditions. Here, a Resistive Touch Screen is often preferred, because it reacts to firm touches and is less sensitive to water droplets and electromagnetic interference than many capacitive alternatives.[5][2][4]

South Korean panel PC makers and monitor suppliers build rugged HMIs with metal housings, sealed front panels, and wide‑temperature LCDs combined with a Resistive Touch Screen front. This combination supports long‑term, reliable operation on production lines, in machine tools, and on outdoor or mobile equipment used in industries such as mining, logistics, and construction.[8][2][6][7]

Public kiosks, ticketing machines, and information terminals are another important area where a Resistive Touch Screen continues to play a role. Enclosures may use vandal‑resistant glass or thick overlays, and users can interact with the system by finger, stylus, or plastic card, which suits the pressure‑based sensing of a Resistive Touch Screen.[3][2][5][6]

South Korean kiosk integrators and digital signage specialists can configure terminals with either capacitive or Resistive Touch Screen fronts depending on location and use case. In outdoor or semi‑outdoor installations where raindrops, condensation, or electromagnetic noise are concerns, a Resistive Touch Screen can deliver more stable and predictable behavior over time.[10][2][4]

Medical devices and laboratory analyzers often require precise, single‑touch interaction with consistent response despite repeated cleaning and different glove types. For these reasons, many medical OEMs still base their equipment on a Resistive Touch Screen, which is easy to validate and stable across long product lifecycles.[3][4][5][6]

Korean suppliers that serve the medical and life‑science markets can add optical bonding, anti‑bacterial coatings, or special front‑glass designs while maintaining the proven Resistive Touch Screen structure underneath. This approach helps manufacturers update device aesthetics without re‑qualifying the fundamental touch sensing technology.[9][4][8]

When planning a project around a Resistive Touch Screen, clear technical specifications help the Korean supplier design an appropriate solution. Key parameters include diagonal size, aspect ratio, active area, resolution of the underlying display, and front‑panel mounting style.[4][5][6][9]

Buyers should also define operating and storage temperature ranges, humidity conditions, and expected exposure to vibration, shock, or chemicals. For a Resistive Touch Screen intended for harsh industrial or outdoor environments, suppliers can recommend stronger substrates, reinforced borders, and optimized controller settings.[11][2][5][4]

A Resistive Touch Screen requires a controller that converts analog signals into digital coordinates for the host system. Typical interfaces include USB, RS‑232, or I2C, and many Korean manufacturers can supply controller boards integrated into the cable harness or PCB of the monitor.[5][8][9][4]

For reliable operation, especially in industrial environments, EMC performance is critical. Manufacturers can adjust grounding, shielding, and firmware filters so that the Resistive Touch Screen remains stable under electrical noise from motors, inverters, and radio devices.[2][6][7][5]

A key advantage of the Resistive Touch Screen is its predictable mechanical lifetime, expressed in millions of touch cycles under specified force. Korean suppliers typically perform durability tests such as repeated tapping, line‑drawing, and edge‑touch testing to confirm performance across the active area.[6][2][4][5]

Customers in safety‑critical industries may request additional verification like temperature‑cycling, humidity‑soak, or salt‑fog testing for the complete Resistive Touch Screen stack. Documented test procedures and reports help OEMs during system certification and long‑term reliability planning.[7][9][3][6]

Successful cooperation on a Resistive Touch Screen project depends heavily on clear communication between buyer and supplier. Korean manufacturers often provide English‑language sales and engineering support to discuss drawings, tolerance requirements, firmware changes, and test feedback.[8][10][2]

Sharing 3D models, mechanical drawings, and UI design concepts allows the supplier to adjust bezel width, tail orientation, and cable length around the Resistive Touch Screen to simplify assembly. Early technical discussions also help prevent mismatches in connector type, controller protocol, or display alignment.[9][4][6][8]

For new programs, buyers should clarify sample lead times, minimum order quantities, and forecast volumes for the chosen Resistive Touch Screen configuration. Many South Korean suppliers emphasize fast sampling and flexible MOQs at the prototype stage, then scale to mass production once designs are frozen.[10][4][8][9]

Because industrial equipment often remains in service for many years, lifecycle planning is important. By discussing expected product lifetime and potential redesign windows, OEMs and Korean manufacturers can agree on strategies for long‑term availability or second‑source alternatives for the Resistive Touch Screen.[2][3][4][10]

South Korea offers a mature, technically advanced environment for sourcing Resistive Touch Screen components and complete HMI solutions across industrial, kiosk, and medical markets. Manufacturers such as Touch & Display, Alpha Display, Inotouch Technology, TLVision, and Hantouch combine strong engineering, diverse product portfolios, and export experience, enabling global OEMs to integrate a reliable Resistive Touch Screen into their equipment with confidence. By defining clear specifications, evaluating supplier capabilities, and planning for lifecycle and testing, buyers can build robust, long‑term partnerships around Resistive Touch Screen technology in South Korea.[4][5][7][8][9][2]

The main benefit is that a Resistive Touch Screen detects pressure rather than skin capacitance, so it works reliably with gloves, stylus pens, and non‑conductive tools in harsh environments. This makes a Resistive Touch Screen ideal for industrial, kiosk, and medical devices where users cannot always touch the screen with bare fingers.[5][6][2][4]

Yes, many South Korean manufacturers have strong track records in industrial and medical markets and design their Resistive Touch Screen modules for long lifecycles and stable supply. With documented testing, quality systems, and export experience, they can support equipment that remains in production and service for many years.[3][7][8][2]

Most Korean suppliers can customize dimensions, mounting holes, tail orientation, and cover‑glass printing around the Resistive Touch Screen to match customer housings and brand identity. They also support integration into full panel PCs or monitors so OEMs receive a ready‑to‑install assembly rather than only a bare Resistive Touch Screen.[8][9][4]

The best starting point is to send display size, mechanical drawings, interface requirements, and environmental conditions, along with target volumes and project schedule. Korean engineers can then propose a suitable Resistive Touch Screen structure, controller, and cost estimate, followed by sample builds for validation.[9][10][4][8]

Yes, many Korean suppliers offer both four‑wire and five‑wire Resistive Touch Screen options to satisfy different durability and accuracy requirements. Five‑wire Resistive Touch Screen panels are often chosen for higher‑end industrial or medical systems where maximum lifetime and stability are required.[11][4][5]

[1](https://www.perplexity.ai/search/4c69768c-a7a6-46df-a689-72902eb72d9a)

[2](https://www.perplexity.ai/search/16f36b24-cf56-4a8e-852e-2b841a6d6cb5)

[3](https://www.perplexity.ai/search/75b5774d-0299-4186-bd96-1fcbb36baaac)

[4](https://www.perplexity.ai/search/8c4d07c3-8925-4b9c-b889-91f751085fe5)

[5](https://www.perplexity.ai/search/429c6446-281e-47cb-874e-a4683a8f89be)

[6](https://www.perplexity.ai/search/1e8de7e7-a5dc-4bfa-a724-3e021f56ad85)

[7](https://www.perplexity.ai/search/148df180-b6bf-4883-969e-a922500318eb)

[8](https://www.perplexity.ai/search/a0e16fa2-aeae-4dc4-b880-a1feaff21f42)

[9](https://www.perplexity.ai/search/e67928ad-14a8-4811-af85-fa97223e4ef3)

[10](https://www.perplexity.ai/search/83e9eab4-ae42-477e-885c-225535d9deb7)

[11](https://www.perplexity.ai/search/f423789b-e5fc-4725-bb40-593f3ada72c0)

Top Resistive Touch Screen Manufacturers and Suppliers in Turkey

Top Resistive Touch Screen Manufacturers and Suppliers in Vietnam

Top Resistive Touch Screen Manufacturers and Suppliers in South Korea

Top Resistive Touch Screen Manufacturers and Suppliers in Japan

Top Resistive Touch Screen Manufacturers and Suppliers in Italy

Top Resistive Touch Screen Manufacturers and Suppliers in Portugal

Top Resistive Touch Screen Manufacturers and Suppliers in Spain