Views: 222 Author: Wendy Publish Time: 2025-12-07 Origin: Site

Content Menu

● What is a Resistive Touch Screen?

● Key Advantages of Resistive Touch Screen Technology

● Typical Applications of Resistive Touch Screen

● Top 10 Resistive Touch Screen Manufacturers in China

>> Leading Chinese Resistive Touch Screen Suppliers

● How to Choose a Resistive Touch Screen Supplier in China

>> Check technical capability and product range

>> Evaluate certifications and quality system

>> Confirm customization and engineering support

● Technical Options in Resistive Touch Screen Design

● Sourcing and Negotiation Tips for Global Buyers

● Using Images and Videos to Market Resistive Touch Screen Solutions

● How Resistive Touch Screen Fits Industrial and Harsh Environments

● Combining Resistive Touch Screen with Other Components

● FAQ About Resistive Touch Screen Sourcing in China

>> 1. What is the main difference between a Resistive Touch Screen and a capacitive touch screen?

>> 2. When should I choose a Resistive Touch Screen instead of capacitive?

>> 4. How do Chinese factories ensure the quality of Resistive Touch Screen products?

>> 5. Can I request customized branding and mechanical design on the Resistive Touch Screen?

China has built a complete industrial chain for Resistive Touch Screen design, glass processing, ITO coating, FPC production, and module assembly, making it one of the best sourcing bases for industrial, medical, and automotive touch projects worldwide. For overseas OEMs and system integrators, choosing the right Resistive Touch Screen partner in China helps balance cost, reliability, and customization flexibility while ensuring long‑term supply.[1][2]

In this guide, ten representative Chinese Resistive Touch Screen manufacturers are introduced, together with key technical parameters, application focus, and sourcing tips for building long‑term cooperation. The article also explains how to use images and videos to present Resistive Touch Screen structure, factory capacity, and real application cases in your own marketing content so you can better convince global customers.[2][3]

A Resistive Touch Screen uses electrical resistance changes between conductive layers to locate the touch position when pressure is applied on the surface. It typically contains a flexible top layer and a rigid bottom layer, both coated with indium tin oxide (ITO), separated by tiny spacer dots that prevent accidental contact.[3][2]

When the user presses the Resistive Touch Screen, the two layers make contact and form a voltage divider, which the controller converts into X‑Y coordinates recognized by the system as a touch point. Because it responds to pressure rather than capacitance, a Resistive Touch Screen can be operated with fingers, gloves, stylus pens, or almost any pointed object.[1][3]

To explain this clearly in marketing materials, many companies display cross‑section diagrams of the Resistive Touch Screen stack‑up and short 3D animations that show how pressure closes the circuit between the two ITO layers. Such visualizations help non‑technical buyers quickly understand why a Resistive Touch Screen performs reliably in tough working conditions.[2][3]

One major advantage of the Resistive Touch Screen is its strong performance in harsh or contaminated environments, where liquids, dust, and oil on the surface have limited impact on touch detection. This makes the Resistive Touch Screen a natural fit for industrial machinery, outdoor kiosks, and medical equipment where operators often wear gloves or use tools.[3][1]

Resistive Touch Screen modules are also cost‑effective and mature, supported by a long history of deployment in ATMs, POS systems, and industrial HMIs. Thanks to this maturity, designers can easily find controllers, firmware, and driver libraries for a wide range of embedded platforms when integrating a Resistive Touch Screen.[2][3]

Unlike many capacitive solutions, a Resistive Touch Screen can still work when covered by thicker protective films or glass, which is attractive for anti‑vandal or explosion‑proof panel designs. This flexibility allows engineers to design rugged user interfaces while maintaining reliable single‑touch performance in critical environments.[1][3]

A Resistive Touch Screen is widely used in industrial control panels, PLC HMIs, CNC machines, vending machines, and outdoor kiosks where reliability and glove operation are essential. In these installations, a Resistive Touch Screen is typically mounted behind a protective front panel and designed for continuous use over millions of touches.[1][2]

The medical sector also relies on Resistive Touch Screen solutions in diagnostic devices, portable analyzers, infusion pumps, and pharmacy automation systems. Because staff often wear surgical gloves and require precise, single‑point control, a Resistive Touch Screen remains an ideal choice for many medical HMIs.[2][1]

In the automotive and transportation field, Resistive Touch Screen modules are still used in navigation systems, bus ticketing machines, and aftermarket multimedia devices, especially for cost‑sensitive fleets. Handheld terminals, logistics scanners, and POS terminals also commonly integrate a Resistive Touch Screen because it maintains usability under frequent, heavy operation with stylus or gloved hands.[4][2]

To strengthen your branding, you can present photos or videos of these real‑world installations, showing how a Resistive Touch Screen improves efficiency and safety in each sector. These visuals help potential buyers imagine how your integrated Resistive Touch Screen solutions will work in their own equipment.[4][2]

China hosts many capable Resistive Touch Screen manufacturers that support different industries, from heavy machinery to consumer terminals. Below are ten representative suppliers and touch‑panel companies in China that are active in the Resistive Touch Screen field.[4]

| No. | Company (China) | Core Focus Related to Resistive Touch Screen | Typical Applications / Strengths |

| --- | --------------- | -------------------------------------------- | -------------------------------- |

| 1 | Touch‑China | Develops and produces various Resistive Touch Screen products from small to medium sizes, with strong customization and industrial/automotive focus.[1] | Vehicle HMIs, industrial control, finance terminals, and smart education, supported by ISO9001 and IATF16949 certifications.[1] |

| 2 | Ruixiang Touch Display (RXTP LCD) | Specialized Resistive Touch Screen manufacturer and supplier, offering tailored designs and OEM/ODM service.[5] | Customized Resistive Touch Screen solutions for industrial equipment, medical devices, and commercial terminals with stable performance.[5] |

| 3 | HEAD SUN | Professional Resistive Touch Screen producer offering 4‑wire, 5‑wire, 7‑wire, and 8‑wire products, including industrial types.[6] | Durable, accurate Resistive Touch Screen panels with support for special sizes, interfaces, and strict industrial operating temperatures.[6] |

| 4 | Dongguan ShenXun Electronic Technology | Provides various Resistive Touch Screen modules as a Chinese manufacturer with export experience.[7] | Resistive Touch Screen solutions for advertising machines, consumer devices, and basic industrial HMIs.[7] |

| 5 | DWIN Technology | Integrates Resistive Touch Panel solutions with intelligent TFT modules and its own HMI platform.[8] | Industrial touch HMIs, medical devices, smart home products, and special embedded displays that use Resistive Touch Screen input.[8] |

| 6 | Reshine Display | Supplies custom displays including Resistive Touch Screen and TFT LCD modules designed for harsh environments.[2] | Outdoor and industrial devices where robust, glove‑operable Resistive Touch Screen performance is critical.[2] |

| 7 | CJTouch | Offers Resistive Touch Screen products and industrial display monitors for OEMs.[9] | Industrial monitors, kiosks, and panel PCs with integrated Resistive Touch Screen input for automation and retail projects.[9] |

| 8 | DOPO Tech Group | Provides Resistive Touch Panel products as a China‑based wholesale and OEM supplier.[10] | Batch supply of Resistive Touch Screen panels for kiosk makers, POS integrators, and industrial customers needing stable volume.[10] |

| 9 | Laibao High‑Tech (touch segment) | Produces both capacitive and resistive screens as part of a broader flat‑panel portfolio.[4] | Consumer and industrial displays with both Resistive Touch Screen and capacitive options, emphasizing R&D and innovation.[4] |

| 10 | Platform‑based certified suppliers | Aggregated listings of Resistive Touch Screen factories on major Chinese B2B platforms.[11] | A wide selection of Resistive Touch Screen sizes, structures, and pricing models accessible to global buyers.[11] |

When building long‑term relationships, treat each Resistive Touch Screen manufacturer not just as a component supplier but as a technical partner for system integration. Early technical communication helps you optimize structure, interfaces, and mounting to reduce future redesign costs for your Resistive Touch Screen project.[4][2]

A serious Resistive Touch Screen manufacturer should provide standard 4‑wire and 5‑wire products and, ideally, 7‑wire or 8‑wire structures for high‑reliability applications. Review whether the supplier can combine a Resistive Touch Screen with TFT LCD modules, backlight assemblies, and controller boards into a complete display solution.[6][2]

Datasheets should clearly specify electrical characteristics, surface hardness, touch life cycles, operating temperature, and storage temperature for each Resistive Touch Screen model. This technical transparency makes it easier to compare multiple suppliers and select the best match for your project.[3][2]

Look for Resistive Touch Screen manufacturers that operate under ISO9001 quality systems, and for automotive or transportation projects, IATF16949 can be an important indicator of process discipline. Compliance with CE, RoHS, and sometimes REACH is also necessary for exporting integrated Resistive Touch Screen products to key markets.[1][4]

Request sample quality documents such as control plans, failure mode analysis, and reliability test reports for the Resistive Touch Screen you plan to purchase. These documents demonstrate how the supplier manages risk and ensures consistent quality over long production runs.[2][1]

Most OEM projects require some customization on the Resistive Touch Screen, such as unusual aspect ratios, silk‑screen colors, or special tail (FPC) routing. Good suppliers provide quick DFM feedback, 2D and 3D drawings, and prototype samples so that you can check mechanical fit and usability.[5][2]

In addition, some Chinese manufacturers help with controller selection, firmware tuning, and EMC optimization around the Resistive Touch Screen, which can greatly reduce your engineering workload. Strong technical support becomes especially important when integrating a Resistive Touch Screen into complex equipment like medical analyzers or CNC machines.[8][2]

A modern Resistive Touch Screen project often starts with choosing the right wire configuration and surface treatment. Four‑wire designs are simple and cost‑effective, while five‑wire and above structures move sensing to a single, more robust layer, improving durability in demanding applications.[6][3]

Engineers can specify different surface finishes such as anti‑glare, anti‑fingerprint, or clear gloss for the top sheet of the Resistive Touch Screen. Some projects require hard‑coated films or strengthened glass to resist scratches from stylus or tool use, while keeping the tactile response of the Resistive Touch Screen stable.[6][2]

Controller ICs support various interfaces like USB, RS‑232, and I2C, and often include noise‑filtering algorithms to maintain accurate Resistive Touch Screen operation in electrically noisy environments. Firmware can also be tuned for touch sensitivity, debounce time, and linearity to match specific user habits and applications.[3][2]

When sourcing a Resistive Touch Screen in China, start with a detailed specification document describing diagonal size, active area, cover‑lens thickness, viewing direction, interface, and operating environment. A clear requirement list helps manufacturers quickly determine feasibility and quote accurate prices for your Resistive Touch Screen.[5][2]

It is wise to request engineering samples or small pilot batches of the Resistive Touch Screen before committing to mass production. During this stage, you can evaluate optical clarity, touch response, ESD performance, and compatibility with your enclosure, then fine‑tune the design with the supplier.[5][2]

When negotiating with Chinese factories, consider not only unit price but also tooling cost, payment terms, lead time, and after‑sales support for the Resistive Touch Screen. Maintaining multi‑source options for key Resistive Touch Screen sizes can also reduce supply‑chain risk for long‑life industrial products.[4][2]

High‑quality visual content plays a key role in promoting your Resistive Touch Screen business to global customers. Because most buyers cannot easily visit factories in person, photos and videos become the main tools to communicate professionalism and reliability.[2][4]

You can use the following types of visual materials in your website, catalogs, and social media:

- Factory photos showing ITO film cutting, lamination lines, optical bonding processes, and Resistive Touch Screen reliability test equipment.

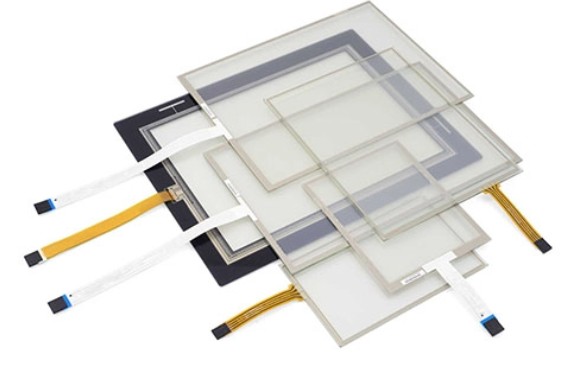

- Close‑up shots of different Resistive Touch Screen sizes, from small handheld panels to large industrial screens, highlighting details like FPC tails and mounting holes.

- Application images of Resistive Touch Screen modules installed in control cabinets, medical analyzers, driver consoles, and outdoor payment kiosks.

- Short explainer videos combining animation and live shooting that demonstrate how a Resistive Touch Screen works, especially under conditions with water droplets, dust, or glove operation.

- Customer interview clips where overseas partners briefly explain how a Chinese Resistive Touch Screen supplier helped them reduce cost, improve durability, or speed up time‑to‑market.

By organizing this material into case studies, product pages, and social posts, you present yourself as an expert integrator of Chinese Resistive Touch Screen technology, which helps build trust with new buyers. This strategy is especially effective when your core business already involves industrial consumables or components and you want to cross‑sell Resistive Touch Screen solutions to the same customer base.[4][2]

In many factories, equipment faces oil, dust, vibration, and electromagnetic noise, all of which can disturb more sensitive interfaces. A Resistive Touch Screen, however, is inherently resistant to many of these factors because it depends on physical pressure instead of a stable human capacitance signal.[3][1]

For example, in a grinding or polishing workshop, airborne particles may settle on the operator panel, but a correctly sealed Resistive Touch Screen continues to respond accurately to gloved touches. In such scenarios, the operator can even use a stylus or tool tip to interact with the Resistive Touch Screen without risking damage to the sensing layers.[3][2]

Industrial HMIs often integrate a Resistive Touch Screen with a sealed front panel rated at IP65 or higher, protecting internal electronics from coolant spray and cleaning chemicals. This combination of mechanical sealing and robust sensing makes the Resistive Touch Screen a reliable choice for harsh environments where downtime is unacceptable.[1][2]

Many Chinese suppliers provide not only the bare Resistive Touch Screen but also full display assemblies and control boards. This integration simplifies procurement because you receive a single, tested module that includes TFT LCD, backlight, driver board, and Resistive Touch Screen in one unit.[8][2]

For equipment builders, this approach shortens development time; they only need to design a mechanical opening and electrical connector for the integrated Resistive Touch Screen display. Some suppliers further offer enclosure design, bracket manufacturing, and even complete HMI box builds, allowing you to outsource much of the hardware work while focusing on software and system integration.[8][4]

If your business already exports machinery or materials, partnering with such a module supplier lets you quickly add a modern Resistive Touch Screen control panel to your existing product lines. This can significantly increase perceived value while adding only a modest cost compared with traditional button‑based control panels.[2][3]

A Resistive Touch Screen remains a crucial technology for industrial, medical, and commercial applications that demand pressure‑based, glove‑friendly input and stable operation in harsh environments. China has developed a comprehensive ecosystem of Resistive Touch Screen manufacturers and integrators that offer broad size ranges, strong engineering support, and competitive pricing for global OEM customers.[3][4]

When you evaluate the top 10 Resistive Touch Screen manufacturers in China, look beyond unit price and pay attention to technical capabilities, certifications, customization flexibility, and long‑term cooperation attitude. By selecting the right partners and presenting their strengths through professional images, videos, and case studies, you can confidently promote high‑quality Resistive Touch Screen solutions to industrial, medical, and automation customers worldwide.[1][2]

A Resistive Touch Screen detects pressure through physical contact between conductive layers, whereas a capacitive touch screen senses changes in an electrostatic field created by a finger or conductive object. Because of this principle, a Resistive Touch Screen works with gloves, stylus pens, or tools and is less affected by surface moisture or dust than many capacitive solutions.[1][3]

You should choose a Resistive Touch Screen for environments involving gloves, tools, moisture, or contamination, such as industrial control panels, outdoor kiosks, and medical devices. For consumer smartphones and tablets where multi‑touch gestures and high transparency are critical, capacitive technology is usually preferred, but industrial HMIs and legacy equipment still rely heavily on Resistive Touch Screen panels.[4][1]

Before requesting a quotation, prepare key parameters including diagonal size, active area, cover‑lens thickness, touch structure, operating temperature range, interface type, and any required certifications for the Resistive Touch Screen. Providing mechanical drawings or 3D models of your housing also helps the supplier optimize the Resistive Touch Screen design and avoid mechanical interference.[5][2]

Reputable Chinese manufacturers run incoming inspection, in‑process QC, and final outgoing tests for each batch of Resistive Touch Screen panels. They typically rely on ISO9001‑based systems, use life‑cycle touch testers, optical measurement equipment, and environmental chambers to verify that the Resistive Touch Screen meets durability and reliability targets.[2][1]

Yes, most Chinese suppliers offer customization such as logo printing, border colors, special cover‑glass shapes, and custom FPC routing for your Resistive Touch Screen. Many also provide fully bonded display modules and ready‑to‑install HMI assemblies, so you can receive a complete, branded Resistive Touch Screen unit for quick integration into your equipment.[8][2]

[1](https://www.sztouchdisplay.com/capacitive-touch-screen/touch-screen.html)

[2](https://www.reshine-display.com/resistive-touch-screen.html)

[3](https://www.orientdisplay.com/touch-panels/resistive-touch-panel/)

[4](https://www.av-display.hk/blog/exploring-touch-screen-manufacturers-in-china)

[5](https://www.rxtplcd.com/resistive-touch-screen/)

[6](https://www.touchlcddisplay.com/resistive-touch-screen/)

[7](https://dgshenxun.goldsupplier.com/748675-Resistive-Touch-Screen/)

[8](https://m.dwin-global.com/resistive-touch-panel/)

[9](https://www.cj-touch.com/supplier-469695-resistive-touch-screen)

[10](https://www.dopotouch.com/supplier-19301-resistive-touch-panel)

[11](https://www.made-in-china.com/products-search/hot-china-products/Resistive_Touch_Screen.html)

Top Resistive Touch Screen Manufacturers and Suppliers in Turkey

Top Resistive Touch Screen Manufacturers and Suppliers in Vietnam

Top Resistive Touch Screen Manufacturers and Suppliers in South Korea

Top Resistive Touch Screen Manufacturers and Suppliers in Japan

Top Resistive Touch Screen Manufacturers and Suppliers in Italy

Top Resistive Touch Screen Manufacturers and Suppliers in Portugal

Top Resistive Touch Screen Manufacturers and Suppliers in Spain