Views: 222 Author: Wendy Publish Time: 2025-12-20 Origin: Site

Content Menu

● Understanding Resistive Touch Screen Technology

● Why Australia Still Uses Resistive Touch Screen Solutions

● Key Application Fields in Australia

● Advantages of Resistive Touch Screen for Harsh Environments

● Representative Australian Players Supporting Resistive Touch Screen Projects

● Customization Options for Industrial Resistive Touch Screen Solutions

● Selecting an Australian Supplier for Resistive Touch Screen Projects

● Cooperation Strategies for Global OEMs and Integrators

● Comparing Resistive Touch Screen and Capacitive for Australian Projects

● FAQ – Resistive Touch Screen in Australia

>> (1) How does a Resistive Touch Screen work?

>> (2) When should I choose a Resistive Touch Screen instead of capacitive?

>> (3) Can Australian suppliers customize industrial Resistive Touch Screen solutions?

>> (4) Are Resistive Touch Screen systems suitable for outdoor installations?

>> (5) Where can engineers source small Resistive Touch Screen modules for development?

Australia is an attractive destination for sourcing industrial displays and Resistive Touch Screen solutions for mining, transportation, automation, retail, and public self‑service projects. For global OEMs, system integrators, and distributors, working with Australian Resistive Touch Screen manufacturers and suppliers offers reliable quality, local engineering support, and stable after‑sales service across demanding environments.[1]

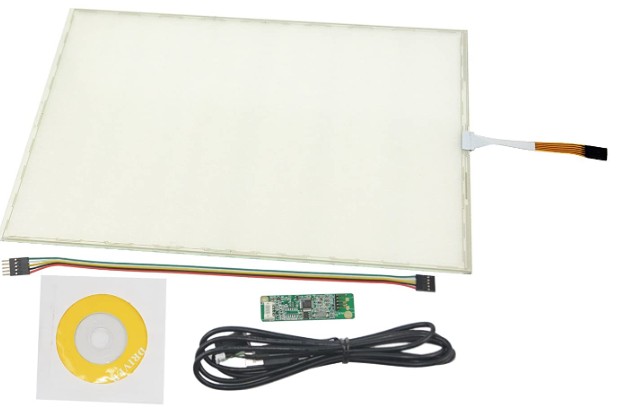

A Resistive Touch Screen is a pressure‑sensitive touch interface made of two thin conductive layers separated by spacer dots, which register a touch when the layers are pressed together. Unlike capacitive panels, a Resistive Touch Screen can be operated with gloves, a stylus, or any object, making it popular in medical, industrial, and outdoor terminals where bare‑finger contact is not always practical.[1]

There are several common structures, such as 4‑wire, 5‑wire, and 8‑wire Resistive Touch Screen designs, each optimized for different levels of accuracy, durability, and cost. In many industrial HMI systems, 5‑wire Resistive Touch Screen panels are preferred because the sensing lines are placed on a durable glass substrate, improving stability and long‑term drift performance.[2]

Engineers and project owners in Australia still select Resistive Touch Screen solutions for harsh or specialized environments despite the rapid growth of capacitive technology. In mining, agriculture, heavy vehicles, and factory automation, a Resistive Touch Screen offers robust glove operation, predictable behavior with liquids or dust, and proven long‑term stability.[3]

For many legacy systems, the control software, drivers, and panel cut‑outs were originally designed around a Resistive Touch Screen interface, so upgrading the hardware with the same technology minimizes redesign costs. Even when capacitive screens are available, a well‑engineered Resistive Touch Screen can provide a more consistent user experience under extreme conditions such as vibration, electrical noise, and frequent chemical cleaning.[4][2]

A Resistive Touch Screen continues to play a significant role in Australia's industrial and public‑sector infrastructure. Local manufacturers and integrators frequently combine industrial displays with either capacitive or Resistive Touch Screen layers, giving project owners flexibility for each use case.[3][4]

Typical application scenarios include:

- Industrial HMI and automation: PLC panels, production line controls, SCADA terminals, and machine diagnostics often use Resistive Touch Screen interfaces for reliable input in dusty and oily environments.[4]

- Mining and heavy vehicles: In‑cab displays for haul trucks, drills, and loaders rely on Resistive Touch Screen panels that can be operated with gloves and withstand shock and vibration.[2]

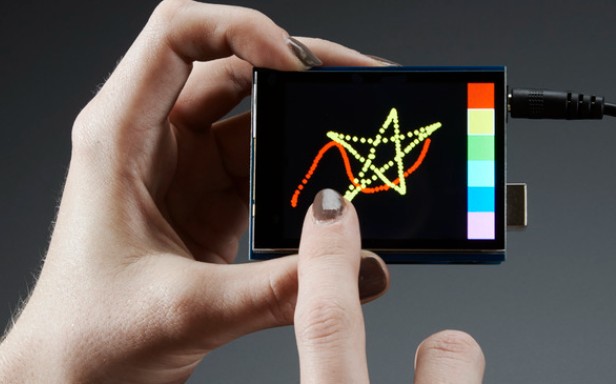

- Medical and laboratory devices: Diagnostic equipment, analyzers, and infusion control systems frequently adopt a Resistive Touch Screen to enable stylus operation and precise point selection on small icons.[4]

- Public kiosks and ticketing: Self‑service ticket machines, wayfinding kiosks, and government service terminals can still use a ruggedized Resistive Touch Screen when high vandal resistance and predictable single‑touch behavior are required.[1]

- Embedded development and education: Small Resistive Touch Screen modules remain popular for Raspberry Pi and microcontroller projects in universities, R&D labs, and maker communities across Australia.[1]

For harsh industrial and outdoor conditions, a Resistive Touch Screen offers several advantages that remain difficult to fully replace with capacitive technology. These benefits are especially relevant for Australian sectors such as mining, energy, transport, and agriculture where environments are dusty, wet, and physically demanding.[2][3]

Key advantages include:

- True glove operation: A Resistive Touch Screen reacts to pressure rather than skin conductivity, so it works reliably with thick gloves, styluses, and non‑conductive tools.[4]

- Stable behavior with liquids and contaminants: Droplets, mud, and dust on the surface usually do not trigger false touches, which is critical for outdoor or food‑processing installations.[2]

- Predictable single‑touch input: Many industrial applications only require one touch point at a time, and a robust Resistive Touch Screen is easier to lock down against unintended multi‑touch gestures.[4]

- Cost‑effective retrofits: When upgrading existing control systems, keeping a Resistive Touch Screen often avoids changes to electronics, firmware, and operator training, saving time and budget.[4]

Australia hosts several manufacturers, distributors, and integrators that can support projects involving a Resistive Touch Screen, either directly or through OEM/OEM‑style cooperation. Many of these companies also offer capacitive solutions, but maintain experience integrating Resistive Touch Screen sensors for demanding use cases.[3][1]

Major categories of players include:

- Industrial panel PC and HMI manufacturers supplying rugged displays with customizable touch options, including Resistive Touch Screen layers.[3]

- Kiosk and enclosure specialists who integrate monitors, PCs, and a chosen Resistive Touch Screen into turnkey terminals for retail, transport, and government.[3]

- Component and module distributors that provide small Resistive Touch Screen panels and controllers for embedded design and low‑volume applications.[5]

Even when a company's marketing emphasizes “PCAP” or “multi‑touch glass,” buyers can often request a Resistive Touch Screen alternative if the project requires glove operation, stylus input, or compatibility with older systems.[4]

For industrial and commercial projects, customization is usually as important as the choice between capacitive and Resistive Touch Screen technologies. Australian suppliers and global partners frequently customize the mechanical, optical, and electronic aspects of a Resistive Touch Screen system to match real‑world environments.[5][4]

Common customization options include:

- Screen size and aspect ratio: From small 3.5‑inch Resistive Touch Screen modules for embedded devices to large 21.5‑inch or 24‑inch industrial panels for control rooms.[2]

- Cover glass and coatings: Anti‑glare, anti‑fingerprint, and chemically strengthened cover glass can be laminated over a Resistive Touch Screen for improved durability and readability.[5]

- Optical bonding: Filling the air gap between LCD and Resistive Touch Screen with optical adhesive reduces internal reflections and improves sunlight readability in outdoor applications.[3]

- Front‑panel design and sealing: Stainless steel or aluminum bezels, gasket designs, and IP‑rated sealing help protect a Resistive Touch Screen from water jets, dust ingress, and cleaning chemicals.[2]

- Controller and interface selection: USB, RS‑232, and I2C controller boards ensure that the Resistive Touch Screen communicates smoothly with industrial PCs, PLCs, or embedded processors.[2]

When selecting an Australian partner for a Resistive Touch Screen project, buyers should go beyond the basic panel specifications and evaluate broader engineering and service capabilities. This ensures that the Resistive Touch Screen will perform reliably throughout the entire product lifecycle rather than just during initial trials.[3][4]

Important evaluation points include:

- Industry experience: Choose suppliers with a track record in your sector—mining, medical, transport, food processing, or retail—so they understand typical Resistive Touch Screen failure modes and design solutions.[2]

- Engineering support: Confirm that the supplier can review drawings, suggest mechanical improvements, and help integrate the Resistive Touch Screen into your housing or cabinet.[5]

- Testing and certification: Ask how the Resistive Touch Screen system is tested for vibration, shock, temperature, humidity, and EMC, and check which standards it meets.[2]

- After‑sales service: Ensure there is clear RMA, warranty, and spare‑parts support for the chosen Resistive Touch Screen models for the full expected usage period.[4]

Global OEMs and project integrators working with Australian touch screen partners can gain more value by treating the supplier as part of the engineering team rather than just a hardware vendor. This is especially true when the project relies on a customized Resistive Touch Screen that must survive harsh service conditions for many years.[4][2]

Recommended cooperation strategies:

- Early‑stage design‑in: Share system concepts, mechanical envelopes, and environmental conditions early so that the supplier can recommend the right Resistive Touch Screen stack‑up and enclosure design.[5]

- Prototype and field trials: Build small batches of units with the selected Resistive Touch Screen and test them in real‑world environments to validate waterproofing, readability, and touch performance.[2]

- Long‑term agreements: Consider framework agreements that lock in the Resistive Touch Screen BOM, pricing, and lifecycle commitments, reducing the risk of unexpected obsolescence.[4]

Although capacitive panels dominate consumer devices, a careful comparison often shows that a Resistive Touch Screen is still the more practical choice in certain Australian applications. Project teams should evaluate technology options based on environment, user behavior, and lifetime cost rather than trend alone.[3][4]

Key contrasts:

- User input: Capacitive supports multi‑touch gestures and light finger input, while a Resistive Touch Screen supports pressured input from gloves and tools in harsh workflows.[4]

- Environmental resistance: A sealed Resistive Touch Screen with proper enclosure can better tolerate contamination on the surface, whereas capacitive panels may suffer from false touches with water or conductive dust.[2]

- Lifetime and maintenance: Industrial‑grade Resistive Touch Screen panels are easily replaceable and use mature controllers, which can simplify long‑term maintenance in remote Australian sites.[5]

Australia offers a mature ecosystem of touch screen manufacturers, kiosk builders, and industrial PC suppliers that can support both capacitive and Resistive Touch Screen projects for domestic and international customers. For global OEMs and integrators, choosing Australian partners for Resistive Touch Screen solutions delivers strong engineering support, reliable quality, and proven performance in demanding real‑world environments such as mining, automation, and public infrastructure.[3][4]

By carefully matching technology to application, and by working closely with experienced local partners, buyers can build long‑term, stable HMI platforms based on a Resistive Touch Screen that remain serviceable and cost‑effective throughout the product lifecycle.[5]

A Resistive Touch Screen works by measuring the change in voltage when two transparent conductive layers touch each other after being pressed together at a specific point. From this change, the controller calculates the coordinates and passes the touch information to the operating system as a mouse‑like input.[2][4]

A Resistive Touch Screen is ideal when your application requires glove operation, stylus precision, or reliable performance in environments containing water, oil, or heavy dust. It is also a practical choice when upgrading legacy equipment originally designed around Resistive Touch Screen controllers and firmware.[4][2]

Yes, many Australian and regional suppliers can design and supply custom industrial hardware that incorporates a Resistive Touch Screen, tailored enclosures, and dedicated electronics. They can adjust screen size, cover glass, sealing, and controller interfaces so that the Resistive Touch Screen matches your HMI requirements and industry standards.[5][3]

When combined with sunlight‑readable LCDs, optical bonding, and IP‑rated front panels, a Resistive Touch Screen can operate reliably in outdoor and semi‑outdoor applications. Proper mechanical design and testing are essential to protect the Resistive Touch Screen against UV exposure, humidity, and temperature cycling common in Australian climates.[3][2]

Engineers can source small Resistive Touch Screen modules and compatible controllers from local and global electronics distributors that support Australian customers. These modules are commonly used with embedded platforms such as Raspberry Pi and industrial microcontrollers for prototyping and product development.[5][4]

[1](https://www.perplexity.ai/search/75b5774d-0299-4186-bd96-1fcbb36baaac)

[2](https://www.perplexity.ai/search/429c6446-281e-47cb-874e-a4683a8f89be)

[3](https://www.perplexity.ai/search/8cad7c0c-2449-408f-9f4d-0e381e7c6c93)

[4](https://www.perplexity.ai/search/1e8de7e7-a5dc-4bfa-a724-3e021f56ad85)

[5](https://www.perplexity.ai/search/e67928ad-14a8-4811-af85-fa97223e4ef3)

Top Resistive Touch Screen Manufacturers and Suppliers in Turkey

Top Resistive Touch Screen Manufacturers and Suppliers in Vietnam

Top Resistive Touch Screen Manufacturers and Suppliers in South Korea

Top Resistive Touch Screen Manufacturers and Suppliers in Japan

Top Resistive Touch Screen Manufacturers and Suppliers in Italy

Top Resistive Touch Screen Manufacturers and Suppliers in Portugal

Top Resistive Touch Screen Manufacturers and Suppliers in Spain