Views: 222 Author: Wendy Publish Time: 2025-12-22 Origin: Site

Content Menu

● Overview of Resistive Touch Screen Technology

● Why France Still Uses Resistive Touch Screen Solutions

● Key Performance Advantages of Resistive Touch Screen

● Supplier Landscape for Resistive Touch Screen in France

● LCDIS and French Distribution of Resistive Touch Screen Panels

● French‑Market Industrial HMI Brands Using Resistive Touch Screen

>> Industrial Panel‑PC and POS Terminals

>> HMI and PLC Vendors in Industrial Sectors

● European Touch Specialists Supporting Resistive Touch Screen Demand

● Global OEM Resistive Touch Screen Makers Supplying France

● Main Application Segments for Resistive Touch Screen in France

● Technical Considerations When Selecting a Resistive Touch Screen

● Comparison: Resistive Touch Screen vs. Capacitive Touch in French Projects

● How a Chinese Abrasives and Refractories Exporter Can Leverage Resistive Touch Screen

● Practical Steps to Source Resistive Touch Screen Solutions for France

● FAQ

>> 1. Why do many French factories still use Resistive Touch Screen HMIs?

>> 2. Can a Resistive Touch Screen meet hygiene and cleaning requirements?

>> 3. Is it possible to upgrade existing French equipment while keeping the Resistive Touch Screen?

>> 4. How should overseas suppliers cooperate with French touch and HMI partners?

>> 5. What documents are important when specifying a Resistive Touch Screen for France?

Resistive Touch Screen technology is still an essential part of the French HMI, industrial automation, POS and medical electronics market, especially where gloves, stylus input and rugged conditions matter more than multi‑touch gestures. For overseas buyers, understanding how Resistive Touch Screen manufacturers and suppliers operate in France—through local distributors, panel‑PC brands and OEM integrators—helps you choose the right partners for industrial and commercial projects.[1][2]

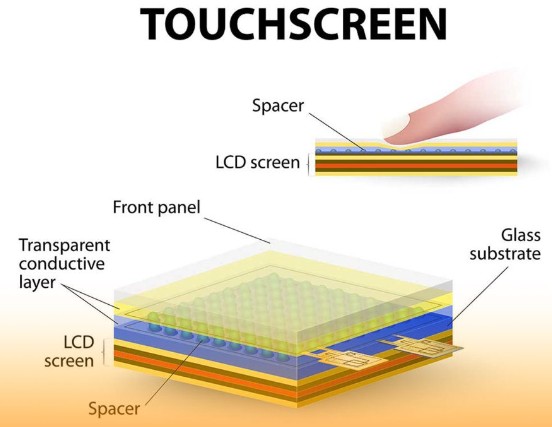

Resistive Touch Screen panels are built from two transparent conductive layers with a narrow gap between them; when pressure is applied, the layers make contact and the controller calculates the touch position. This structure makes a Resistive Touch Screen work with finger, glove, stylus, or any object, which is why many industrial and medical devices still rely on it in France and across Europe.[3][4]

A Resistive Touch Screen normally supports single‑touch input, but it excels in harsh or dirty environments where capacitive technology is less reliable or more expensive. In many projects, designers combine a Resistive Touch Screen panel with rugged housings, IP‑rated fronts and industrial communication interfaces to create long‑life HMI solutions for factories, laboratories and transport systems in France.[5][6]

France has strong industrial, food‑processing, transportation and healthcare sectors, and many machines operate in dusty, wet, or high‑noise areas where a Resistive Touch Screen remains the most practical interface. Machine builders and OEMs also value the predictable cost and mature supply chain of Resistive Touch Screen modules for long‑lifecycle equipment that must be supported for many years.[7][8]

In French hospitals and laboratories, designers often choose a Resistive Touch Screen where staff must wear thick gloves, and precise stylus input is needed for monitoring and configuration tasks. These Resistive Touch Screen HMIs are usually sealed behind protective bezels and integrated with fanless embedded PCs or panel‑PCs so they can run around the clock with minimal maintenance.[9][10]

A Resistive Touch Screen is typically less expensive than a projected capacitive solution and has simpler controller electronics, which is attractive for cost‑sensitive French projects. It is also tolerant of electromagnetic interference and can work reliably in electrically noisy industrial environments when paired with properly shielded cables and controllers.[11][12]

Because a Resistive Touch Screen detects pressure, it supports input from pens, barcode‑scanner tips, or stylus devices without needing special electrical properties or finger contact. In food plants, outdoor kiosks under rain covers, or dusty workshops in France, this gives the Resistive Touch Screen a clear reliability advantage and reduces the risk of mis‑touches.[4][13]

While many Resistive Touch Screen panels are manufactured in Asia, French buyers usually work through European distributors, HMI brands and value‑added resellers that understand local standards and support needs. When discussing “Top Resistive Touch Screen Manufacturers and Suppliers in France”, it is practical to include not only purely French producers but also regional partners that actively serve the French market.[2][3]

Typical supplier types that French OEMs and integrators rely on for Resistive Touch Screen projects include:

- Local distributors and component specialists that stock Resistive Touch Screen panels and controllers for quick delivery.

- Industrial HMI brands that integrate Resistive Touch Screen fronts into panel‑PCs, operator terminals and POS systems.

- European touch solution providers that offer both Resistive Touch Screen and capacitive products to French customers.

- Global OEM touch manufacturers that ship custom Resistive Touch Screen modules into France via distribution partners.

These channels together create a complete ecosystem where a French buyer can source anything from a single Resistive Touch Screen for repair to thousands of custom modules for OEM production.[1]

LCDIS is an example of a France‑based specialist that focuses on LCD and touch solutions, including Resistive Touch Screen panels for industrial and embedded applications. As a local partner, such a distributor helps French companies match Resistive Touch Screen sensors with appropriate LCD sizes, controller boards and interface options without needing to manage overseas procurement directly.[14][15]

Technical teams in these distributors can advise on glass thickness, anti‑glare finishing, controller type and cable routing, all of which influence the real‑world performance of a Resistive Touch Screen. For smaller and mid‑sized French OEMs, this engineering support is often more valuable than saving a small amount on the unit price of the Resistive Touch Screen itself.[13][7]

Several panel‑PC and POS brands active in France offer terminals that either still rely on Resistive Touch Screen panels or evolved from resistive‑based designs. These products are widely used in retail, hospitality and light industrial environments where operators may use touch pens or gloved hands during long working hours.[10][3]

For French buyers, such panel systems provide ready‑to‑deploy platforms where the Resistive Touch Screen is already integrated, certified, tested and covered under local warranty and support programs. This is ideal for software‑focused companies that want to concentrate on applications, not on the low‑level integration of Resistive Touch Screen hardware.[16][17]

Industrial automation suppliers serving the French market provide panel HMIs and operator stations built around analog Resistive Touch Screen fronts. They design sealed front panels with metal or plastic enclosures and integrate Resistive Touch Screen panels behind protective windows to achieve IP‑rated protection against dust and splashing liquids.[8][18]

These Resistive Touch Screen HMIs are widely deployed in French factories because they offer long availability, robust mechanics and predictable behavior in high‑vibration, temperature‑fluctuating environments. Compared with consumer tablets, an industrial Resistive Touch Screen terminal is designed for many years of continuous operation, with standard mounting options and easy replacement procedures.[6][19]

Beyond France itself, several European touch solution providers still maintain product lines of Resistive Touch Screen panels for industrial customers who value stability and simplicity. They may be better known for projected capacitive touch technology, yet they keep Resistive Touch Screen offerings to support legacy designs and cost‑sensitive applications.[4][5]

These European specialists often provide multi‑size catalogues of analogue Resistive Touch Screen sensors, combined with optional controller boards and customization services such as silk‑printed borders or specific tail layouts. French integrators source these Resistive Touch Screen components through local resellers, ensuring compliant logistics and straightforward technical communication.[11][13]

At the component level, many of the Resistive Touch Screen panels used in French devices originate from global OEM manufacturers in China, Taiwan, Korea or North America. These companies specialize in large‑volume production and can supply standard 4‑wire or 5‑wire Resistive Touch Screen sensors, as well as custom‑shaped panels and bonded assemblies.[12][3]

Global suppliers increasingly offer complete front assemblies where the Resistive Touch Screen, cover glass, optical adhesive and sometimes an LCD are delivered as a ready‑to‑mount module. This helps French HMI designers reduce integration risks and ensures that optical and mechanical tolerances are controlled by a single specialist.[20][2]

Resistive Touch Screen technology is still widely used in several French application segments:

- Industrial automation: machine HMIs, process control panels and operator terminals running PLC or SCADA systems.

- Transportation and ticketing: certain ticket machines, kiosks and onboard terminals where simple menus and stylus input are sufficient.

- Medical and laboratory equipment: monitors, analyzers and diagnostic devices that must support gloved operation and regular cleaning.

- POS and self‑service: legacy or cost‑optimized cashier terminals and service points requiring robust, predictable tactile feedback.

In each of these segments, the choice of Resistive Touch Screen is driven more by reliability, glove compatibility, and cost than by the need for multi‑touch or gesture support.[7]

When evaluating a Resistive Touch Screen for French projects, engineers must consider both electrical and mechanical parameters. Contact resistance, linearity, and response time directly affect the feel of a Resistive Touch Screen, while glass thickness, coatings and mounting method affect durability and readability.[5][4]

Key selection points include:

- Size and aspect ratio of the Resistive Touch Screen relative to the underlying LCD.

- Type of resistive technology (4‑wire, 5‑wire, 8‑wire) and its impact on accuracy and durability.

- Interface options offered by the controller (USB, serial, I2C, SPI) and driver availability for the target operating system.

- Environmental ratings, including operating temperature, humidity tolerance and resistance to chemicals used in cleaning.

By analyzing these factors early in a project, French OEMs can avoid redesigns and ensure that the chosen Resistive Touch Screen meets both performance and lifecycle expectations.[11]

Although projected capacitive touch (PCAP) dominates smartphones and consumer tablets, a Resistive Touch Screen competes effectively in specific industrial and professional niches. In France, that competition is not purely technical; it involves lifecycle expectations, user habits and installed base considerations.[3][6]

Important contrasts include:

- Input method: a Resistive Touch Screen works with any object and thick gloves, while capacitive touch usually needs direct finger contact or special gloves.

- Environmental robustness: a Resistive Touch Screen is often more tolerant of heavy contamination on the surface, while capacitive can suffer from water films or conductive dust.

- Cost and complexity: Resistive Touch Screen modules and controllers tend to be simpler and cheaper, which is attractive for lower‑volume industrial products.

As a result, many French companies adopt a mixed strategy, using capacitive touch for new, design‑driven user interfaces and maintaining Resistive Touch Screen solutions where ruggedness and compatibility are more critical.[13]

For a Chinese company specialized in abrasives and refractory materials, understanding the French Resistive Touch Screen landscape is useful at two levels: internal automation and customer communication. Internally, equipping kilns, grinding lines and classification systems with modern HMIs based on a Resistive Touch Screen can improve process monitoring and traceability.[21][8]

Externally, whenever you present solutions to French buyers, highlighting that your equipment already uses reliable, industrial‑grade Resistive Touch Screen interfaces helps build confidence in your technical capability. Joint projects with French integrators can combine your materials expertise and their local HMI know‑how, resulting in full systems that are easier to operate, maintain and certify.[2][6]

To source Resistive Touch Screen modules or complete HMIs for use in France, a structured approach is recommended. This helps both French and overseas buyers navigate the range of suppliers and ensure long‑term supply stability.[14][3]

Suggested steps:

1. Define the use case and environment

- Clarify whether the Resistive Touch Screen will be used in food processing, heavy industry, medical, or retail.

- Determine glove use, cleaning methods, brightness needs, and target lifetime.

2. Decide on module vs. finished HMI

- Choose between bare Resistive Touch Screen sensors, bonded LCD assemblies, or complete enclosed HMIs.

- For smaller teams, finished panel‑PCs or terminals simplify integration.

3. Shortlist suppliers

- Combine France‑based distributors, European touch specialists and global OEM makers that support Resistive Touch Screen technology.

- Request technical datasheets, sample Resistive Touch Screen units, and pricing for expected volumes.

4. Test and validate

- Evaluate responsiveness, accuracy, and durability of each Resistive Touch Screen option in realistic conditions.

- Confirm driver compatibility with your embedded operating systems.

5. Secure long‑term agreements

- Negotiate supply, change‑notification procedures and last‑time‑buy policies for the chosen Resistive Touch Screen variants.

Following these steps makes it easier to align expectations between engineering, purchasing and end users when deploying Resistive Touch Screen‑based systems in France.[16]

A Resistive Touch Screen remains a strong, practical choice for many French industrial, medical and commercial applications, even as capacitive solutions gain ground in consumer electronics. By leveraging France‑based distributors, European touch specialists and global OEM manufacturers, buyers can obtain reliable and customizable Resistive Touch Screen modules or complete HMIs that match long‑term project requirements.[4][14]

For your Chinese abrasives and refractory business, integrating and promoting robust Resistive Touch Screen HMIs in production equipment can demonstrate process reliability and digital competence to French partners. Understanding how and why French markets still depend on Resistive Touch Screen technology helps you speak the same technical language as local integrators and positions your company as a modern, automation‑ready supplier.[21][2]

Many French factories still use Resistive Touch Screen HMIs because they work reliably with gloves, tolerate dust and moisture, and have proven stability over long equipment lifecycles. Replacing a well‑understood Resistive Touch Screen with a more complex capacitive interface is rarely justified when the process requirements have not changed.[7][13]

Yes, a Resistive Touch Screen can meet strict hygiene and cleaning requirements if it is integrated behind a sealed front with appropriate gasket design. Designers choose compatible cleaning chemicals and smooth bezels so that operators can sanitize the Resistive Touch Screen surface without damaging the sensor.[6][10]

In many cases, you can upgrade controllers, PLCs or software while keeping the same Resistive Touch Screen size and mounting, which reduces retrofit complexity. Some OEMs even design adapter boards so new electronics can drive legacy Resistive Touch Screen panels used in older French machines.[19][11]

Overseas suppliers should share clear mechanical drawings, environmental requirements and user‑interface concepts so French partners can recommend appropriate Resistive Touch Screen or HMI platforms. Regular communication on lifecycle plans, testing feedback and local certification needs helps ensure that all parties support end users effectively.[2][16]

Important documents include detailed specifications for the Resistive Touch Screen, controller datasheets, EMC and safety test reports, and installation guidelines. When equipment is destined for the French or wider EU market, suppliers must also provide compliance declarations and manuals aligned with local regulations and languages.[3][14]

[1](https://www.perplexity.ai/search/a2d5090d-75cc-4e44-bea8-b11bcf8db5c1)

[2](https://www.perplexity.ai/search/5e7787b8-e73d-43e9-9602-79feef053642)

[3](https://www.perplexity.ai/search/e67928ad-14a8-4811-af85-fa97223e4ef3)

[4](https://www.perplexity.ai/search/148df180-b6bf-4883-969e-a922500318eb)

[5](https://www.perplexity.ai/search/86a01543-a5ed-4902-b5f3-965d5a98b849)

[6](https://www.perplexity.ai/search/b65740d9-8d48-414c-ae82-f5b9550dc917)

[7](https://www.perplexity.ai/search/43c35f27-4898-44c3-a5e4-98d72631e96d)

[8](https://www.perplexity.ai/search/8f58fb44-5f40-4df0-8476-4edc77600444)

[9](https://www.perplexity.ai/search/b2e20159-71e5-42ff-872d-eb31c0757952)

[10](https://www.perplexity.ai/search/2d1c6a78-772f-4838-8432-d017b9dabffd)

[11](https://www.perplexity.ai/search/8efd782c-6188-4b8b-8561-fd93353f35a2)

[12](https://www.perplexity.ai/search/d52ffa1d-26e3-401b-af7e-e52003acaaeb)

[13](https://www.perplexity.ai/search/a40c2a80-e0c9-4c3d-b4f5-143f15e5b64f)

[14](https://www.perplexity.ai/search/10129df6-18c1-439a-8dea-45180b0b592b)

[15](https://www.perplexity.ai/search/dc3c16a2-dca1-43e1-9aa9-7c8239cd761f)

[16](https://www.perplexity.ai/search/fdb63934-8d3d-4d0a-8fad-e2ae72fb57f3)

[17](https://www.perplexity.ai/search/e6267308-ab7c-48cb-ab5b-416114fd2c58)

[18](https://www.perplexity.ai/search/7d262f3e-7606-41e4-81d8-1d4b45841a9c)

[19](https://www.perplexity.ai/search/15d50a2b-83c9-4fdb-9e4b-94cfa12e8c0f)

[20](https://www.perplexity.ai/search/6ddf6a99-2459-4a83-b0b5-21b3de111b71)

[21](https://www.perplexity.ai/search/441b3ff8-9629-44fe-8ba8-0a77bb12661d)

Top Resistive Touch Screen Manufacturers and Suppliers in Turkey

Top Resistive Touch Screen Manufacturers and Suppliers in Vietnam

Top Resistive Touch Screen Manufacturers and Suppliers in South Korea

Top Resistive Touch Screen Manufacturers and Suppliers in Japan

Top Resistive Touch Screen Manufacturers and Suppliers in Italy

Top Resistive Touch Screen Manufacturers and Suppliers in Portugal

Top Resistive Touch Screen Manufacturers and Suppliers in Spain