Views: 222 Author: Wendy Publish Time: 2025-12-20 Origin: Site

Content Menu

● Understanding Resistive Touch Screen Technology

● Why Source Resistive Touch Screen Solutions from Malaysia

● Typical Product Types Using Resistive Touch Screen Technology

● Leading Malaysian Companies Offering Resistive Touch Screen Products

>> XYREON Technology Sdn. Bhd.

>> NetEon – Industrial Panel PC and HMI Supplier

>> Axiomtek (Malaysia Channel)

>> Component Distributors and HMI Brands

● Key Industrial Applications of Resistive Touch Screen Solutions in Malaysia

● Technical Considerations When Choosing a Resistive Touch Screen

● How to Evaluate Malaysian Resistive Touch Screen Suppliers

● Cooperation Models for Global OEMs

● Best Practices for Applying Resistive Touch Screen in Harsh Environments

● FAQ – Resistive Touch Screen Sourcing in Malaysia

>> 1. What are the main advantages of a Resistive Touch Screen for industrial use?

>> 2. How does a Resistive Touch Screen compare with capacitive touch for Malaysian HMIs?

>> 3. Can Malaysian suppliers customize Resistive Touch Screen sizes and housings?

>> 4. What documents should buyers request before ordering a Resistive Touch Screen?

Malaysia is becoming a strategic sourcing base for industrial Resistive Touch Screen solutions serving automation, HMI panels, kiosks, and rugged equipment across Southeast Asia and global export markets. For foreign OEMs, system integrators, and distributors, working with Malaysian Resistive Touch Screen manufacturers and suppliers offers a competitive balance of cost, customization, and reliable logistics into ASEAN, the Middle East, Europe, and America.[1][2]

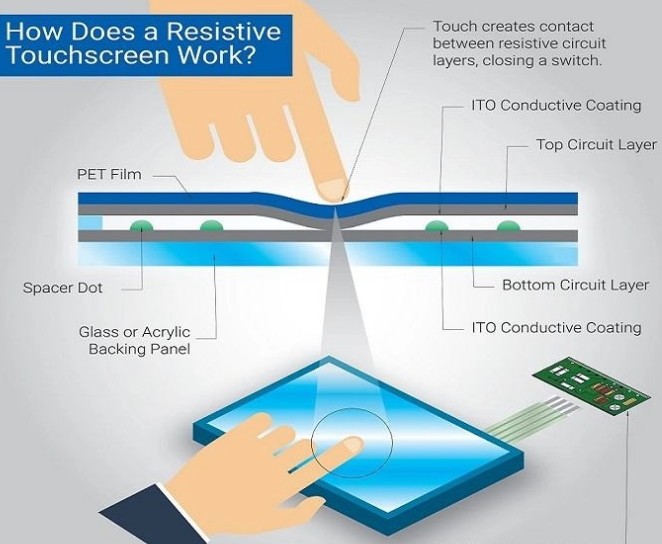

Resistive Touch Screen panels detect input through pressure on multiple conductive layers, allowing operation with gloves, stylus, or even while wet or dirty, which is ideal for industrial and harsh environments. Compared with capacitive designs, a Resistive Touch Screen usually has lower cost, simpler controllers, and better tolerance for electromagnetic noise, making it a popular choice for HMIs, control panels, and legacy systems.[2][3]

A modern Resistive Touch Screen in Malaysia is commonly based on 4‑wire or 5‑wire analog designs, which offer stable performance, high compatibility with PLC/HMI brands, and straightforward integration in panel PCs and industrial monitors. Many Malaysian industrial display suppliers now offer both resistive and capacitive options in the same mechanical footprint, so OEMs can choose the most suitable touch technology for each project.[4][2]

Malaysia has developed a strong ecosystem of industrial PC, HMI, and touch monitor suppliers that integrate Resistive Touch Screen panels into rugged, IP‑rated enclosures. These suppliers often combine local engineering support with imported panels and controllers from global brands, giving buyers a flexible mix of quality and pricing.[3][2]

Several factors make Malaysia attractive for sourcing Resistive Touch Screen solutions:

- Strategic location with easy logistics to ASEAN, China, India, the Middle East, Europe, and Oceania.

- English‑speaking engineering and sales teams, which simplifies communication, documentation, and after‑sales service for international partners.

- Growing experience with Industry 4.0, resulting in extensive field know‑how on how to apply Resistive Touch Screen interfaces in demanding industrial automation and smart factory environments.[4]

Malaysian manufacturers and system integrators deliver various product types built around Resistive Touch Screen technology to match different industrial and commercial needs. The main categories include:[2]

- Industrial touch monitors: Open‑frame or panel‑mount LCDs with front‑mounted Resistive Touch Screen sensors for machine control panels.

- Panel PCs and box PCs with touch: Embedded computers combined with Resistive Touch Screen fronts, used as operator terminals on production lines or in logistics hubs.

- HMI terminals and operator panels: Compact Resistive Touch Screen devices acting as user interfaces for PLCs, inverters, pumps, and process equipment.

- Kiosk and POS terminals: Systems where a durable Resistive Touch Screen is preferred for cost‑sensitive or outdoor applications, or where stylus input is required.[3]

These product types are widely used in manufacturing, food processing, water treatment plants, logistics centers, and building automation systems, helping operators interact efficiently via a durable Resistive Touch Screen interface.[5]

Below are representative companies in Malaysia that design, supply, or integrate Resistive Touch Screen solutions for industrial and commercial use. These firms often support both resistive and capacitive touch, but are valuable partners if your priority is a robust Resistive Touch Screen interface.[2]

Greentouch Malaysia is a touch screen solution provider offering a broad portfolio of touch display products, including open‑frame monitors and industrial touch displays for kiosks, digital signage, and industrial applications. While Greentouch is widely associated with multi‑touch and projected capacitive solutions, its industrial range can be configured with Resistive Touch Screen options for environments where glove operation, dust, or contamination are critical concerns.[3][2]

Greentouch typically supports different display sizes and mechanical formats, so OEMs can integrate a Resistive Touch Screen into cabinets, consoles, and kiosks with minimal redesign. Combined with local technical support, this gives overseas buyers a convenient route to implement Resistive Touch Screen solutions in customized projects across Southeast Asia and global markets.[1][2]

XYREON Technology is a Malaysian industrial solution provider specializing in LCD displays, touch displays, and automation components. Its catalog of touch displays includes industrial monitors that can be configured with resistive or capacitive technologies, enabling OEMs to adopt a Resistive Touch Screen when projects emphasize durability and input flexibility instead of gesture control.[4][2]

XYREON often positions its products for factory automation, control rooms, and embedded applications, where a Resistive Touch Screen helps operators operate HMIs accurately even when wearing gloves or using a stylus. For export‑oriented projects, XYREON's experience with industrial standards can support long‑term deployments of Resistive Touch Screen systems in demanding conditions.[1][3]

iMS Motionet, based in northern Malaysia, focuses on motion and control technology and supplies industrial panel PCs and related automation components. Many of its industrial panel PC offerings can integrate Resistive Touch Screen panels for reliable operation in dusty or oily production lines, packaging machines, and robotics systems.[2][4]

Because motion control and robotics often operate in environments with vibration, electrical noise, and airborne contaminants, robust Resistive Touch Screen interfaces are especially valuable. iMS Motionet can provide panel PCs where the Resistive Touch Screen is tightly sealed, ensuring long‑term reliability while connected to servo drives, PLCs, and sensors.[5][2]

NetEon operates as a Malaysian supplier of industrial panel PCs and computers designed for harsh and commercial environments. Its systems frequently integrate LCDs with touch panels, and many configurations are available with rugged Resistive Touch Screen front panels suitable for food processing, logistics, and factory automation.[4][2]

For hygiene‑sensitive industries such as food, beverage, and pharmaceuticals, the ability to clean the front surface repeatedly without damaging the Resistive Touch Screen is essential. NetEon's designs typically emphasize sealed enclosures and flat front surfaces, enabling easier sanitation while maintaining stable Resistive Touch Screen performance over long service life.[5][2]

Axiomtek, a global industrial PC brand, offers industrial flat monitors and panel PCs that support both resistive and projected capacitive touch options. Through Malaysian distribution and integration partners, Axiomtek provides industrial touch monitors that can be equipped with a Resistive Touch Screen for legacy system upgrades and glove‑based operation.[2][4]

For OEMs that ship equipment worldwide, working through Axiomtek's Malaysian channel helps ensure consistent quality standards and long‑term product availability of Resistive Touch Screen platforms. The combination of global certifications and local support makes these solutions attractive for industries such as oil and gas, transportation, and public utilities.[1][3]

Besides local integrators, Malaysian buyers and exporters can source Resistive Touch Screen components and HMIs through major distributors and international brands active in the country. These channels provide standalone Resistive Touch Screen sensors, HMI terminals, and operator panels designed for direct mounting on machines and control cabinets.[4][2]

Well‑known HMI brands typically offer analog resistive variants of their operator panels for use with gloves or stylus input, especially in industrial automation and infrastructure. For OEMs building their own enclosures, purchasing a complete HMI terminal with an integrated Resistive Touch Screen is often the fastest way to deploy a reliable user interface across multiple machine models.[3][4]

A Resistive Touch Screen is especially popular in Malaysian industrial and commercial scenarios where robustness and input flexibility are more important than multi‑touch gestures. Typical applications include:[3]

- Factory and process automation: HMIs on mixers, conveyors, packaging machines, presses, and CNC equipment where operators frequently wear gloves or have dirty hands.

- Food and beverage production: Resistive Touch Screen panel PCs in cleanrooms and production halls that must endure regular wash‑downs and chemical cleaning.

- Logistics and warehousing: Touch terminals on forklifts, picking stations, and loading docks, where the Resistive Touch Screen must remain readable and responsive under vibration and changing temperatures.

- Water and wastewater treatment plants: Outdoor or semi‑outdoor operator panels where high humidity and condensation require stable Resistive Touch Screen behavior.[5]

In each of these environments, the primary requirement is reliable actuation and clear feedback, which a properly designed Resistive Touch Screen can deliver even when conditions are far from ideal. This robustness explains why resistive technology remains widely adopted despite the growth of capacitive solutions in consumer electronics.[2][3]

When selecting a Malaysian Resistive Touch Screen solution, engineers must balance electrical, mechanical, and environmental factors. Some important technical aspects include:[4]

- Touch type (4‑wire vs 5‑wire): 4‑wire designs are common and cost‑effective, while 5‑wire Resistive Touch Screen panels usually offer improved durability and long‑term stability, especially for industrial use.

- Optical performance: Additional layers in a Resistive Touch Screen can slightly reduce brightness and contrast, so many suppliers compensate with higher‑brightness LCDs or anti‑glare coatings.

- Surface hardness and scratch resistance: Protective coatings and cover lenses help prevent marks caused by frequent stylus or fingertip operation on the Resistive Touch Screen.

- Calibration and controller tuning: Accurate calibration and quality controllers are essential to ensure repeatable, precise touch registration over the full screen area.[2]

By addressing these points early in the design phase, OEMs can ensure that the chosen Resistive Touch Screen delivers the required user experience and lifetime performance.[3]

Selecting the right Malaysian partner for a Resistive Touch Screen project involves both technical and commercial evaluation. Key steps include:[2]

- Define application requirements clearly: Document environmental conditions, glove types, cleaning procedures, brightness needs, and expected lifetime for the Resistive Touch Screen.

- Request detailed documentation: Obtain datasheets, drawings, controller specifications, and test reports relevant to the Resistive Touch Screen products being considered.

- Run pilot projects: Start with sample orders to validate performance in real operating conditions, including vibration, temperature, and contamination.

- Assess support and communication: Confirm that sales and engineering teams can respond quickly to questions, firmware updates, and customization requests involving the Resistive Touch Screen hardware.[4]

For global buyers, maintaining regular communication and periodic reviews of field performance helps strengthen the relationship and ensures that the Resistive Touch Screen solution continues to meet evolving requirements.[1]

Global OEMs and system integrators can adopt several cooperation models when working with Malaysian Resistive Touch Screen suppliers. Common approaches include:[2]

- Direct sourcing of monitors or panel PCs: Purchasing complete units with integrated Resistive Touch Screen panels, preconfigured for the OEM's control software.

- Co‑design and customization: Collaborating with local engineers to adapt enclosures, mounting methods, and I/O while keeping the standardized Resistive Touch Screen as the main interface.

- Hybrid sourcing: Using Malaysian partners to assemble imported LCD and touch components into localized systems, optimizing lead time and cost for regional markets.[4]

These cooperation modes give buyers flexibility in cost structure, branding, and after‑sales support while leveraging Malaysia's experience with Resistive Touch Screen integration.[3]

A Resistive Touch Screen can deliver long lifetimes in harsh industrial environments if properly specified and protected. Best practices include:[5]

- Selecting IP‑rated enclosures and ensuring that front bezels are sealed to prevent ingress of dust and liquids around the Resistive Touch Screen frame.

- Using suitable cleaning agents and procedures that do not attack the surface coatings or adhesives of the Resistive Touch Screen.

- Implementing UI designs with large buttons and simple navigation, reducing operator errors and extending the useful life of the Resistive Touch Screen under frequent use.

- Periodically verifying calibration and response, especially in applications with heavy vibration or large temperature swings.[2]

By combining robust hardware and thoughtful UI design, Malaysian suppliers and global OEMs can maximize the value of Resistive Touch Screen technology in demanding fields such as metals processing, chemicals, and infrastructure.[4]

Resistive Touch Screen technology remains a vital solution for industrial, commercial, and embedded applications that demand simple, robust, and glove‑friendly operation. Malaysia has developed a capable network of manufacturers, integrators, and distributors that can deliver complete Resistive Touch Screen monitors, panel PCs, and components tailored to a wide range of sectors.[3][2]

By focusing on key players such as Greentouch Malaysia, XYREON Technology, iMS Motionet, NetEon, and Malaysian channels of global brands, international buyers can access cost‑effective and reliable Resistive Touch Screen products with strong engineering support. Careful evaluation of technical specifications, environmental ratings, and cooperation models enables OEMs to build long‑term partnerships and integrate Malaysian Resistive Touch Screen solutions into global equipment and automation projects.[1][4]

A Resistive Touch Screen allows input with fingers, gloves, stylus, or other objects because it detects pressure rather than body capacitance, which is crucial for many industrial and outdoor applications. It also tends to be more tolerant of dust, moisture, and electrical noise, giving factories and infrastructure projects a reliable human–machine interface even in harsh conditions.[5][3]

A Resistive Touch Screen usually offers lower cost, simpler controllers, and better support for gloved or stylus input, but it typically provides less multi‑touch capability and slightly lower optical clarity than capacitive touch. In Malaysian industrial HMIs, many buyers choose a Resistive Touch Screen where environmental robustness and operator ergonomics are more important than gesture control and sleek aesthetics.[4][2]

Many Malaysian industrial display and panel PC suppliers can customize enclosure materials, mounting options, interface ports, and branding while retaining a standard Resistive Touch Screen sensor. OEMs can request front panel logos, stainless‑steel housings, or different IP ratings to match sector‑specific standards for food, pharmaceutical, or heavy‑industry applications.[2][4]

Buyers should request full datasheets, mechanical drawings, controller specifications, environmental test reports, and relevant certifications for any Resistive Touch Screen product. It is also helpful to obtain clear lifecycle statements and sample units to verify performance in real operating environments before moving into mass production.[3][2]

Overseas buyers can start with pilot lots of Resistive Touch Screen units, followed by in‑house validation or third‑party inspection to check optical quality, responsiveness, and environmental resistance. Long‑term quality control can be maintained by setting documented inspection criteria, requesting production updates, and planning periodic audits or technical meetings with the Malaysian supplier.[1][4]

[1](https://www.perplexity.ai/search/d360ec76-edb5-4245-ad8e-f42a207eb83d)

[2](https://www.perplexity.ai/search/e67928ad-14a8-4811-af85-fa97223e4ef3)

[3](https://www.perplexity.ai/search/22bce6c2-62b0-438c-b6ab-b3418fe23e9b)

[4](https://www.perplexity.ai/search/ed46ac5f-1a6e-4e55-a5ad-9328c044ea5c)

[5](https://www.perplexity.ai/search/441b3ff8-9629-44fe-8ba8-0a77bb12661d)

Top Resistive Touch Screen Manufacturers and Suppliers in Turkey

Top Resistive Touch Screen Manufacturers and Suppliers in Vietnam

Top Resistive Touch Screen Manufacturers and Suppliers in South Korea

Top Resistive Touch Screen Manufacturers and Suppliers in Japan

Top Resistive Touch Screen Manufacturers and Suppliers in Italy

Top Resistive Touch Screen Manufacturers and Suppliers in Portugal

Top Resistive Touch Screen Manufacturers and Suppliers in Spain