Views: 222 Author: Wendy Publish Time: 2025-12-22 Origin: Site

Content Menu

● Why Resistive Touch Screen Technology Still Matters in Russia

● Overview of the Resistive Touch Screen Market in Russia

● Key Types of Resistive Touch Screen Solutions Used in Russia

● Representative Resistive Touch Screen Suppliers Serving Russia

>> International Resistive Touch Screen Specialists

>> Display and Touch Solution Brands Active in Russia

● How Russian Integrators Use Resistive Touch Screen Technology

● Major Application Sectors for Resistive Touch Screen in Russia

>> Industrial Automation and Machinery

>> Power, Utilities, and Energy

>> Transportation, Logistics, and Public Infrastructure

>> Retail, Banking, and Self‑Service Terminals

● Technical Characteristics of Resistive Touch Screen Solutions

● Customization Options for Russian Resistive Touch Screen Projects

>> Electrical and Interface Customization

>> Environmental and Durability Enhancements

● Cooperation Models Between Russian Buyers and Global Resistive Touch Screen Suppliers

>> Distributor and Integrator Channels

● Best Practices for Sourcing Resistive Touch Screen Products for Russia

● How Resistive Touch Screen Compares with Other Technologies in Russian Use Cases

● FAQ – Resistive Touch Screen in Russia

>> (2) Are Resistive Touch Screen panels suitable for outdoor use in Russian winters?

>> (3) Can existing machines in Russia be upgraded with Resistive Touch Screen HMIs?

>> (4) What size range of Resistive Touch Screen is most common in Russian industrial applications?

>> (5) How can Russian buyers ensure long‑term support for their chosen Resistive Touch Screen models?

Russia is a growing market for industrial HMI, kiosks, and automation systems that still rely heavily on Resistive Touch Screen technology because of its durability, low cost, and stable performance in harsh environments. For global OEMs, system integrators, and distributors, understanding the ecosystem of Resistive Touch Screen manufacturers and suppliers in Russia is essential to plan sourcing, customization, and long‑term project support.

Resistive Touch Screen solutions remain popular in Russia because they work reliably with gloves, stylus, and in environments where dust, oil, and moisture are common, such as factories, mining, and transportation hubs. In addition, Resistive Touch Screen HMIs offer stable operation in low temperatures and can be integrated into sealed enclosures, which is critical for outdoor kiosks and remote industrial stations across Russia's wide climatic zones.

- Resistive Touch Screen panels are generally less sensitive to electromagnetic interference than many consumer‑grade devices, which benefits industrial automation and power systems.

- Compared with purely consumer capacitive interfaces, a robust Resistive Touch Screen can deliver long lifetimes and predictable behavior in mechanically demanding environments.

The Russian Resistive Touch Screen market is closely linked to the modernization of industrial equipment and public infrastructure. As legacy control panels and mechanical switches are replaced by digital HMIs, demand for rugged and cost‑effective Resistive Touch Screen interfaces continues to expand.

- Much of the market demand focuses on operator panels, rugged monitors, vending and payment kiosks, and information terminals in transportation hubs and public facilities.

- Russian integrators often purchase Resistive Touch Screen sensors or complete touch display modules from international manufacturers, then assemble them into locally engineered HMIs, control cabinets, and kiosks tailored to domestic standards.

Russia's geographic scale and climate diversity also shape the market. Many installations are located in regions with extreme cold, dust, vibration, or limited maintenance access, where a sealed Resistive Touch Screen solution with simple single‑touch operation is often preferable to more delicate multi‑touch technologies.

Russian projects use several categories of Resistive Touch Screen products depending on application, environment, and integration level.

- Bare resistive sensors: 4‑wire and 5‑wire Resistive Touch Screen sensors supplied as clear overlays that OEMs mount in front of their own LCDs. These allow maximum flexibility in mechanical design and bezel layout.

- Integrated touch modules: Resistive Touch Screen laminated directly onto an LCD module, delivered as a combined unit ready for mounting into a front panel or housing.

- Industrial touch monitors: Enclosed displays with a Resistive Touch Screen front panel, usually with VESA or panel‑mount options, designed for control rooms, production lines, and terminal applications.

- Panel PCs and HMIs: Full computers with a Resistive Touch Screen integrated into the front, including processor, memory, storage, and industrial I/O for direct machine or PLC connection.

Within these categories, buyers can specify different sizes, aspect ratios, brightness levels, and front‑panel sealing options. This flexibility makes Resistive Touch Screen solutions suitable for compact handheld service tools as well as large wall‑mounted operator stations.

Although many touch companies are located outside Russia, they actively support Russian customers with standard and custom Resistive Touch Screen solutions through distributors, local partners, or direct export.

International touchscreen manufacturers provide:

- Standard analog Resistive Touch Screen sensors in popular sizes for kiosks, ATMs, medical carts, and industrial HMIs.

- Custom Resistive Touch Screen designs that match Russian clients' mechanical drawings, including special shapes, cutouts, and mounting borders.

These suppliers often combine Resistive Touch Screen sensors with TFT LCD displays, backlights, and driver boards to ship complete modules that Russian integrators can install into metal or plastic enclosures with minimal additional work.

Global display brands and industrial PC vendors support the Russian market by offering:

- Industrial monitors with Resistive Touch Screen fronts, designed for panel mounting or use in control consoles.

- Panel PCs where customers can choose between Resistive Touch Screen and projected capacitive options according to project requirements.

These solutions are particularly attractive for machine builders and system integrators who prefer to buy a tested, certified unit rather than assemble their own combination of display, touch, and electronics.

Russian system integrators and equipment builders typically design full operator terminals around imported Resistive Touch Screen sensors or complete touch‑display modules.

- On the mechanical side, the Resistive Touch Screen is sealed into the front panel using gaskets, frames, and sealants to achieve IP‑rated protection against dust, oil, and moisture. This is vital for heavy industry, mining, and outdoor applications.

- On the electronic side, the Resistive Touch Screen controller interfaces via USB or serial ports to industrial PCs, SBCs, or PLC‑based systems, with careful grounding and shielding to avoid noise from motors, drives, and power equipment.

Integrators also localize the interface for Russian operators, combining the Resistive Touch Screen front panel with on‑screen elements, color schemes, and fonts that match workplace standards and safety requirements.

Resistive Touch Screen technology serves a wide range of Russian industries where reliability and glove operation are more important than multi‑touch gestures.

In factories, processing plants, and assembly lines, Resistive Touch Screen HMIs are used for:

- Machine start‑stop control, recipe management, alarms, and parameter adjustments.

- Visualization of process data, trends, and status indicators, replacing arrays of physical switches and meters.

A Resistive Touch Screen allows operators to work with oily or dusty hands and still interact accurately with on‑screen buttons and menus.

In power plants, substations, and utility control rooms, Resistive Touch Screen HMIs support:

- Monitoring of electrical parameters and switching states.

- Control of distributed equipment over SCADA or industrial networks.

These environments require robust front panels that can withstand electrical noise, and a Resistive Touch Screen is a proven choice for such conditions.

In transportation and public services, Resistive Touch Screen solutions appear in:

- Ticket vending machines, check‑in terminals, and information kiosks at stations and airports.

- Operator panels for rolling stock, depots, and logistics hubs where temperatures can drop significantly and staff commonly use gloves.

Retail, banking, and service sectors use Resistive Touch Screen interfaces for:

- Payment kiosks, top‑up machines, and loyalty program terminals.

- Information points in shopping centers and public institutions where single‑touch interactions are sufficient and vandal resistance is critical.

To better understand why many Russian buyers still favor Resistive Touch Screen technology, it helps to review its core technical characteristics.

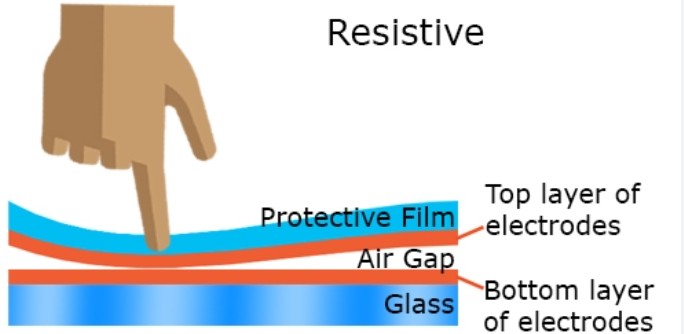

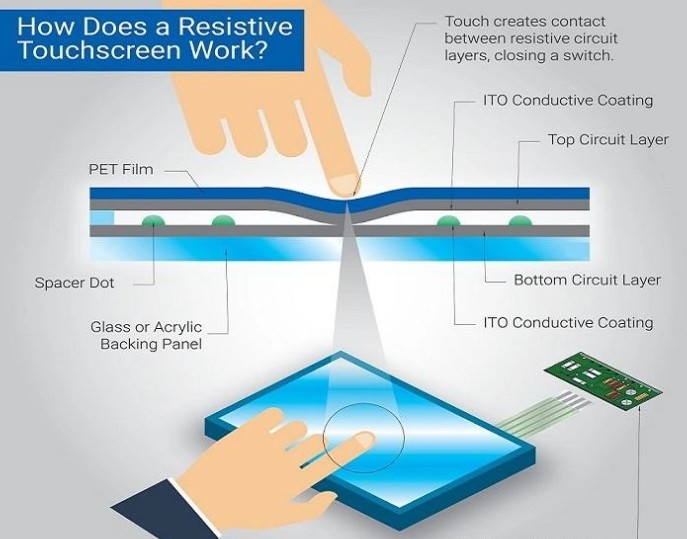

- Structure: A Resistive Touch Screen typically consists of two transparent conductive layers separated by tiny spacers. When pressure is applied, the layers contact, changing resistance at the touch position.

- Input methods: Because the sensor detects pressure rather than electrical capacitance, a Resistive Touch Screen responds to finger, stylus, and gloves, including thick work gloves used in Russian industrial sites.

- Resolution and accuracy: Resistive Touch Screen accuracy is sufficient for buttons, sliders, and simple text input, with fine control possible when using styli.

- Power and EMC: Resistive Touch Screen controllers generally consume little power and can be designed to resist interference, which is important near heavy industrial equipment.

While Resistive Touch Screen technology does not support advanced multi‑touch gestures as smoothly as capacitive sensors, it excels in environments where reliability, simple interactions, and broad input compatibility are more important than gestures.

Russian OEMs and integrators can access a wide variety of customization options from Resistive Touch Screen manufacturers and module suppliers.

- Tailored cover glass or film thickness to match impact resistance requirements.

- Custom bezels, borders, and mounting holes so the Resistive Touch Screen fits perfectly into existing panels or housings.

- Anti‑glare, anti‑reflection, or anti‑fingerprint surface treatments to maintain readability under different lighting conditions.

- Choice of controllers supporting USB, RS‑232, or other industrial interfaces used in Russian equipment.

- Firmware tuning to match touch sensitivity, debounce behavior, and calibration parameters for specific applications.

- Compatibility with common operating systems used in industrial PCs, such as Windows, Linux, or real‑time OS platforms.

- Extended temperature ranges to cope with Russian winter conditions and unheated installations.

- Higher IP ratings through better sealing between the Resistive Touch Screen and enclosure.

- Protective films or glass overlays that increase resistance to scratches, impacts, and vandalism.

Because many Resistive Touch Screen factories are located abroad, Russian companies often adopt structured cooperation models to ensure reliable supply and smooth project execution.

Some Russian OEMs work directly with Resistive Touch Screen and display manufacturers:

- Jointly developing custom modules that match the OEM's mechanical design, branding, and lifecycle requirements.

- Agreeing on long‑term supply plans, including safety stocks and last‑time‑buy arrangements, to avoid disruptions during product changes.

Other buyers prefer to collaborate with regional distributors and integrators:

- Distributors hold inventory of standard Resistive Touch Screen sensors, touch monitors, and panel PCs, reducing lead times.

- Integrators design complete enclosures, control cabinets, and software interfaces, delivering turnkey systems where the Resistive Touch Screen is just one component of a broader solution.

Both models aim to ensure that Resistive Touch Screen based equipment installed across Russian sites can be serviced, updated, and replaced consistently over many years.

When sourcing Resistive Touch Screen solutions for Russian projects, following best practices helps minimize technical and logistic risk.

- Pilot testing: Start with small pilot batches of Resistive Touch Screen panels or HMIs to validate performance in real Russian environments, including low temperatures, vibration, dust, and humidity.

- Documentation and specifications: Request complete mechanical drawings, electrical schematics, interface descriptions, and environmental test reports for every Resistive Touch Screen model used.

- Lifecycle management: Discuss product roadmap and end‑of‑life procedures with suppliers to avoid sudden discontinuation of critical Resistive Touch Screen components.

- Logistics and compliance: Ensure that customs codes, certification documents, and packaging are prepared correctly for shipments into Russia to prevent delays and damage.

By applying these practices, buyers can integrate Resistive Touch Screen technology into long‑lifecycle machinery and public infrastructure with greater confidence.

For Russian projects, the decision between Resistive Touch Screen and other touch technologies depends on application priorities.

- When multi‑touch gestures, high transparency, and sleek consumer‑style designs are crucial, projected capacitive (PCAP) may be preferred.

- When glove operation, stylus precision, and low‑temperature reliability dominate, a Resistive Touch Screen is often more practical.

- For extremely harsh, wet, or explosive environments, some projects combine Resistive Touch Screen panels with additional physical buttons or use alternative input devices where touch is not feasible.

In many cases, mixed fleets exist: some machines use Resistive Touch Screen HMIs for rugged operation, while others adopt capacitive touch for more modern control rooms or operator stations.

Resistive Touch Screen technology continues to play an important role in Russia's industrial, infrastructure, and self‑service sectors because of its robustness, glove compatibility, and resilience in harsh climates. By working with experienced Resistive Touch Screen manufacturers, module suppliers, and Russian integrators, OEMs and project owners can build reliable HMI and kiosk solutions that perform consistently across demanding environments and long product lifecycles.

Many Russian projects still choose Resistive Touch Screen solutions because they work reliably with thick gloves, stylus, and in dusty or oily environments where capacitive sensors may be less stable. In addition, Resistive Touch Screen HMIs can operate in wide temperature ranges and are typically easier to integrate into sealed industrial enclosures.

Yes, suitable Resistive Touch Screen panels can be used outdoors in Russian winters when combined with appropriate LCDs, heaters, and enclosures. Engineers should specify extended temperature ranges and adequate sealing to ensure the Resistive Touch Screen remains responsive and protected against moisture and ice.

Existing machines can often be upgraded by replacing mechanical control panels with Resistive Touch Screen monitors or panel PCs. The upgrade involves redesigning the front panel, installing the Resistive Touch Screen device, and adapting the control software so operators can perform all functions via the new HMI.

Common industrial sizes range from about 7 inches to 21.5 inches, covering small machine interfaces and larger overview panels. However, Resistive Touch Screen suppliers can provide custom sizes and aspect ratios to match specific Russian machinery, kiosks, or cabinet layouts when needed.

Russian buyers should work with suppliers that offer clear lifecycle policies, long‑term availability guarantees, and last‑time‑buy options. Maintaining detailed documentation and agreeing on compatible replacement models helps ensure that Resistive Touch Screen components can be serviced and replaced throughout the equipment's lifetime.

Top Resistive Touch Screen Manufacturers and Suppliers in Turkey

Top Resistive Touch Screen Manufacturers and Suppliers in Vietnam

Top Resistive Touch Screen Manufacturers and Suppliers in South Korea

Top Resistive Touch Screen Manufacturers and Suppliers in Japan

Top Resistive Touch Screen Manufacturers and Suppliers in Italy

Top Resistive Touch Screen Manufacturers and Suppliers in Portugal

Top Resistive Touch Screen Manufacturers and Suppliers in Spain