Views: 222 Author: Wendy Publish Time: 2025-12-20 Origin: Site

Content Menu

● Overview of Resistive Touch Screen Technology

● Why Source Resistive Touch Screen Solutions in Singapore?

● Types of Resistive Touch Screen Products Available

>> Fully integrated touch display modules

>> Industrial HMIs and panel PCs

● Key Considerations When Selecting a Resistive Touch Screen

>> Electrical and controller interface

>> Optical performance and coatings

>> Mechanical robustness and IP protection

● Common Application Scenarios in and Around Singapore

>> Industrial automation and smart factories

>> Marine, offshore, and transportation

>> Medical, laboratory, and industrial instruments

>> Kiosks and specialty terminals

● Cooperation Models for Global Buyers Working with Singapore Partners

>> Partnering with integrators and panel PC manufacturers

>> Direct cooperation with overseas factories

● Practical Tips for Choosing a Resistive Touch Screen Partner

● FAQ

>> 1. What is a Resistive Touch Screen and how does it work?

>> 2. When should I choose a Resistive Touch Screen instead of capacitive?

>> 3. Are Resistive Touch Screen products still widely used around Singapore?

>> 4. Can a Resistive Touch Screen be used outdoors or in harsh environments?

>> 5. How do I start working with a Singapore partner for a custom Resistive Touch Screen project?

Singapore is a strategic sourcing hub for Resistive Touch Screen solutions serving industrial automation, kiosks, transportation, medical devices, and marine systems across Southeast Asia and global markets. Many companies around Singapore supply Resistive Touch Screen panels, industrial HMIs, and integrated touch panel PCs that combine reliable hardware with strong engineering support.[1] For international buyers sourcing from Resistive Touch Screen manufacturers and suppliers, understanding the local producers, product ranges, and quality standards is the key to successful cooperation.

A Resistive Touch Screen uses two transparent conductive layers separated by tiny spacers; when pressure is applied, the layers make contact and the controller calculates the touch point from the change in resistance. Because a Resistive Touch Screen responds to any pressure source—finger, stylus, glove, or tool—it remains popular in harsh industrial and outdoor environments where capacitive panels may struggle.[2]

Compared with capacitive technology, a Resistive Touch Screen generally has lower cost and power consumption, while offering a simpler interface and predictable single‑touch behavior. Typical structures include 4‑wire and 5‑wire Resistive Touch Screen designs, with 5‑wire versions optimized for long‑term durability and stable calibration in heavy‑use systems.[3][2]

Singapore offers a mature electronics ecosystem, regional logistics advantages, and many distributors that stock Resistive Touch Screen panels and complete HMI systems from global brands. Buyers can combine Singapore's strong import/export infrastructure with technical support from engineering‑focused companies to speed up design‑in and after‑sales service.[4][5]

For overseas OEMs and system integrators, sourcing Resistive Touch Screen components through Singapore reduces lead times into ASEAN markets and simplifies customs, warehousing, and regional distribution. At the same time, Singapore‑linked partners often coordinate with factories in China, Japan, Taiwan, or Europe for custom Resistive Touch Screen sizes and integrated display assemblies.[6][3]

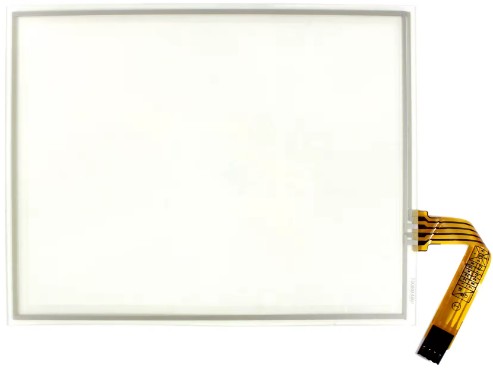

Many projects use a standalone Resistive Touch Screen overlay bonded to a standard LCD or TFT module. These overlays are available in a wide variety of sizes and aspect ratios, allowing industrial designers to upgrade existing displays with a cost‑effective touch interface.[5][7]

A typical overlay includes the Resistive Touch Screen sensor, tail connector, and sometimes a bezel or mounting tape to attach it to the underlying display. Engineers then connect the overlay to a controller board that converts the Resistive Touch Screen signals into USB, serial, or other host‑compatible interfaces.[2][6]

Another common option is a fully integrated module that combines an LCD, backlight driver, and Resistive Touch Screen in one compact assembly. This simplifies mechanical design for OEMs because the module already includes a matching active area and mounting points for both display and touch.[7][4]

Integrated Resistive Touch Screen modules are widely used in handheld terminals, HMI panels, testing equipment, and industrial handheld instruments where compact size and straightforward assembly are important. Such modules often come with long‑term availability commitments, which is essential for industrial and medical projects with long product life cycles.[4][6]

Industrial HMI units and panel PCs are complete systems with housing, CPU, I/O, and a front‑mounted display equipped with a Resistive Touch Screen. These products are designed for installation in control cabinets, console panels, machine doors, or wall mounts in factories, ships, and process plants.[8][9]

A Resistive Touch Screen front panel allows operators to navigate screens, set parameters, and acknowledge alarms even while wearing gloves or using stylus pens in oily or dusty environments. Singapore‑linked suppliers frequently offer rugged HMI and panel PC families that can be configured with Resistive Touch Screen fronts for specific industries such as marine, oil and gas, and food processing.[10][11]

One of the most important decisions is the controller interface used to connect the Resistive Touch Screen to the host system. Many modern controllers support USB HID, making the Resistive Touch Screen appear to the operating system as a standard pointing device without extra drivers.[8][2]

Legacy or deeply embedded systems may use RS‑232 or I⊃2;C interfaces for Resistive Touch Screen controllers, especially in industrial or medical environments where long‑term driver stability matters. Matching the Resistive Touch Screen controller interface to both existing hardware and operating system drivers helps reduce integration risk and development time.[5][4]

Although a Resistive Touch Screen adds an extra layer above the display, careful design can maintain good brightness and clarity. Modern Resistive Touch Screen films are engineered for high transmission and low haze, supporting sharp text and clear graphics in industrial HMIs and instrumentation.[9][7]

Anti‑glare and anti‑reflection surface treatments are essential when a Resistive Touch Screen is used under strong lighting or near windows. Some Resistive Touch Screen surfaces also incorporate hard coatings to improve scratch resistance and reduce visible wear from long‑term stylus or glove use.[6][2]

Mechanical robustness is a major advantage of a well‑designed Resistive Touch Screen. The flexible top layer can withstand millions of actuations if the Resistive Touch Screen is properly designed and not subjected to sharp, damaging forces.[10][2]

For industrial and marine environments, designers often combine a Resistive Touch Screen with IP‑rated front panels that use gaskets and sealed bezels to protect against water, dust, and chemical splashes. In some cases, a Resistive Touch Screen can be mounted behind protective glass or polycarbonate windows, as long as the design preserves sufficient flexibility for accurate touch detection.[11][8]

In factories and process plants, Resistive Touch Screen HMIs are used to monitor production lines, adjust process parameters, and perform maintenance diagnostics. Operators appreciate the ability to use stylus pens or gloved hands on Resistive Touch Screen HMIs during hot or contaminated processes where bare fingers are not practical.[1][10]

Because many PLC and SCADA systems have long service lives, Resistive Touch Screen HMIs provide a stable, familiar interface that can run legacy software and maintain consistent behavior across line upgrades. Singapore's role as a regional hub allows such Resistive Touch Screen‑based automation equipment to be deployed across neighboring countries with coordinated service and support.[4][6]

Marine panel PCs and navigation consoles often rely on Resistive Touch Screen front panels because they remain responsive under vibration and with gloves or wet hands. Offshore platforms and port facilities also deploy Resistive Touch Screen HMIs for crane controls, loading systems, and environmental monitoring panels.[9][11]

In rail and public transport, Resistive Touch Screen displays appear in driver cabins, maintenance terminals, and some ticketing or back‑office systems. Singapore's strong maritime and transport sectors create ongoing demand for robust Resistive Touch Screen solutions that can withstand humidity, salt, and temperature swings.[7][1]

Many analyzers, diagnostic instruments, and industrial testers still favor Resistive Touch Screen interfaces for precise single‑point input. Users can reliably tap small on‑screen buttons and fields with a stylus, which is especially useful in crowded interfaces and multi‑step workflows.[2][5]

In cleanroom, pharmaceutical, and hospital environments, a Resistive Touch Screen can be operated with disposable gloves, simplifying hygiene and contamination control. Long‑term product consistency also makes Resistive Touch Screen‑based instruments attractive for regulated industries that prefer minimal interface changes.[10][4]

While many modern retail kiosks use capacitive technology, a Resistive Touch Screen still appears in budget‑sensitive or specialized terminals. Examples include ticket dispensers, access control units, vending machine interfaces, and service terminals in industrial or semi‑outdoor locations.[3][7]

In such cases, a Resistive Touch Screen may be chosen for compatibility with stylus input, robustness against vandalism, or tolerance of moisture or dust in sheltered outdoor environments. Singapore's focus on smart city and infrastructure projects ensures ongoing niche demand for purpose‑built Resistive Touch Screen kiosks and panels.[5][9]

Global OEMs commonly source standard Resistive Touch Screen modules and HMIs through large distributors that serve Singapore and the wider Asia‑Pacific region. Distributors maintain inventory, handle import and export processes, and offer engineering support for selecting and testing Resistive Touch Screen options.[6][4]

This approach is ideal for moderate‑volume or multi‑project customers who need a wide selection of Resistive Touch Screen sizes and brands without committing to a single factory. It also allows fast sampling and replacement if an initial Resistive Touch Screen choice does not meet performance or compatibility expectations.[9][2]

When projects require customized housings, I/O, or software integration, OEMs often cooperate with HMI integrators and panel PC manufacturers that build complete systems around a Resistive Touch Screen. These partners can design mechanical enclosures, specify CPU and communication modules, and integrate the Resistive Touch Screen controller and display.[11][10]

A Singapore‑based integrator may source the Resistive Touch Screen modules from factories in China or other regions, then add value through system assembly, testing, certification, and long‑term maintenance support. This model suits industrial, marine, and transportation customers who prefer a ready‑to‑install Resistive Touch Screen system rather than just a component.[1][8]

For high‑volume or highly customized projects, buyers can work directly with Resistive Touch Screen factories in China or other manufacturing centers, while using Singapore offices or partners as regional coordination hubs. In such cases, the Singapore entity may handle project management, logistics, and quality coordination, while the factory manages design, tooling, and mass production of the Resistive Touch Screen components.[3][2]

This hybrid model allows close technical communication with the Resistive Touch Screen manufacturer while still benefiting from Singapore's business environment and regional connectivity. It is particularly attractive for long‑running product families where securing stable Resistive Touch Screen supply and consistent specifications is critical.[5][6]

- Clarify application requirements: Define environmental conditions, glove or stylus use, expected life cycle, and any regulatory standards before selecting a Resistive Touch Screen design or supplier.[10]

- Evaluate sample performance: Order samples and run tests for optical clarity, touch responsiveness, calibration stability, and durability in realistic operating conditions for the Resistive Touch Screen.[2]

- Check long‑term availability: Confirm product roadmaps, last‑time‑buy policies, and drop‑in replacement options for the chosen Resistive Touch Screen models.[4]

- Review engineering support: Ensure the partner can provide reference schematics, drivers, and tuning guidance for the Resistive Touch Screen controller and firmware.[8]

By following these steps, buyers can narrow down suitable Resistive Touch Screen options and choose partners that match both technical and commercial goals.[6]

A Resistive Touch Screen remains a practical, cost‑effective, and robust choice for many industrial, marine, medical, and kiosk applications where glove operation, stylus input, or harsh conditions are involved. Singapore's ecosystem of distributors, HMI integrators, and panel PC specialists enables global buyers to source high‑quality Resistive Touch Screen panels, complete HMIs, and rugged systems with strong regional logistics and technical support.[1][2]

By carefully comparing Resistive Touch Screen specifications, interface options, environmental ratings, and supplier capabilities, OEMs and system integrators can build stable projects that operate reliably over long product lifetimes. Combining Singapore‑based supply channels with established global Resistive Touch Screen brands offers a balanced path between cost, flexibility, and long‑term serviceability for demanding applications.[5][6]

A Resistive Touch Screen consists of two flexible, transparent conductive layers separated by spacers; when pressed, the layers contact and the controller calculates X‑Y coordinates from resistance changes. Because a Resistive Touch Screen senses pressure, it works with fingers, stylus pens, gloves, and many tools in industrial or medical environments.[2][10]

A Resistive Touch Screen is ideal when the application needs glove or stylus operation, simple single‑touch input, and tolerance of dust, dirt, and moisture. It is also preferred when cost, low power consumption, or compatibility with older embedded systems is more important than multi‑touch gestures or sleek glass aesthetics.[2][5]

Yes, Resistive Touch Screen panels and HMIs are still widely used in industrial automation, marine systems, medical and laboratory devices, and specialized kiosks around Singapore and the broader region. Many suppliers and integrators continue to support Resistive Touch Screen solutions because they perform reliably in demanding environments and legacy systems.[1][4]

Many industrial Resistive Touch Screen products are designed to operate across wide temperature ranges and to resist dust, liquids, and mechanical wear, especially when installed in sealed, IP‑rated enclosures. Outdoor performance still depends on the underlying display brightness and optical treatments, but a rugged Resistive Touch Screen can function reliably in marine, factory, and utility applications.[11][9]

Typically, you contact a distributor or integrator, describe the requirements for display size, resolution, interface, and environment, and request recommendations for suitable Resistive Touch Screen modules or systems. After evaluating samples, you agree on specifications, pricing, and long‑term supply terms so the partner can coordinate with upstream Resistive Touch Screen manufacturers and support your project lifecycle.[3][6]

[1](https://www.perplexity.ai/search/3c7a4e09-c627-4b43-84a5-e9160acf1085)

[2](https://www.perplexity.ai/search/429c6446-281e-47cb-874e-a4683a8f89be)

[3](https://www.perplexity.ai/search/e67928ad-14a8-4811-af85-fa97223e4ef3)

[4](https://www.perplexity.ai/search/148df180-b6bf-4883-969e-a922500318eb)

[5](https://www.perplexity.ai/search/2897a38c-b22a-4b7b-b739-a1443dfcfeeb)

[6](https://www.perplexity.ai/search/c9fb2641-1dab-4400-b888-b5ed1f7e0410)

[7](https://www.perplexity.ai/search/3032bf1b-b28b-4363-97ea-8c70a153bf70)

[8](https://www.perplexity.ai/search/c4af2c72-57ed-467c-b8f0-aad614f6d817)

[9](https://www.perplexity.ai/search/f5f7870d-8e52-4e59-95b0-543c254dceb5)

[10](https://www.perplexity.ai/search/d360ec76-edb5-4245-ad8e-f42a207eb83d)

[11](https://www.perplexity.ai/search/8f958145-c010-4d52-868e-f2e648cc42eb)

Top Resistive Touch Screen Manufacturers and Suppliers in Turkey

Top Resistive Touch Screen Manufacturers and Suppliers in Vietnam

Top Resistive Touch Screen Manufacturers and Suppliers in South Korea

Top Resistive Touch Screen Manufacturers and Suppliers in Japan

Top Resistive Touch Screen Manufacturers and Suppliers in Italy

Top Resistive Touch Screen Manufacturers and Suppliers in Portugal

Top Resistive Touch Screen Manufacturers and Suppliers in Spain