Views: 222 Author: Wendy Publish Time: 2025-12-20 Origin: Site

Content Menu

● Why Switzerland for Resistive Touch Screen Sourcing

● Overview of Resistive Touch Screen Technology

● Key Benefits of Resistive Touch Screen for Industrial Use

● Key Swiss Players Involved in Resistive and Industrial Touch

● SCHURTER – Customized Resistive Touch Screen Expert

● FORTEC Switzerland – Display and Touch Integration

● CSC Electronic AG – Sourcing Partner for Touch Solutions

● Fabrimex Systems – Industrial Display and HMI Solutions

● Industrial Sectors Using Resistive Touch Screen in Switzerland

● Medical and Laboratory Applications

● Comparing Resistive Touch Screen and Capacitive Solutions

● Selecting a Swiss Resistive Touch Screen Partner

● Practical Steps to Start a Project

● Cooperation Models for Global OEMs

● Quality, Testing, and Certification

● How a Chinese Abrasives & Refractory Supplier Can Cooperate

● Content Ideas for Visual and Video Enhancement

● FAQ – Resistive Touch Screen Sourcing in Switzerland

>> 1. What is a Resistive Touch Screen and why is it still popular in Switzerland?

>> 2. Which Swiss companies can provide Resistive Touch Screen solutions?

>> 3. How do Swiss suppliers customize a Resistive Touch Screen for my project?

>> 4. Can I source both Resistive Touch Screen and capacitive solutions from the same Swiss partner?

>> 5. How should an overseas OEM start cooperation with a Swiss Resistive Touch Screen supplier?

Switzerland offers a specialized ecosystem for high‑reliability human–machine interfaces (HMIs), including industrial displays and Resistive Touch Screen solutions serving automation, medical, transportation, and precision equipment sectors. For global OEMs and system integrators, Swiss Resistive Touch Screen manufacturers and Suppliers combine strong engineering, customization, and quality management, making the country a strategic sourcing base for advanced touch HMI projects.[1][2][3]

Switzerland is widely recognized for precision engineering, long‑term reliability, and strict quality standards in electronics and industrial systems. These strengths perfectly match the demands of Resistive Touch Screen projects that must operate 24/7 in harsh or safety‑critical environments.[2][3][1]

- Many Swiss suppliers focus on industrial, medical, and transportation HMIs rather than low‑cost consumer products, which fits the typical usage of Resistive Touch Screen panels.[1][2]

- Swiss companies often provide custom design, lifecycle management, and local technical support, helping OEMs reduce design risk and ensure stable supply of Resistive Touch Screen components.[3][2]

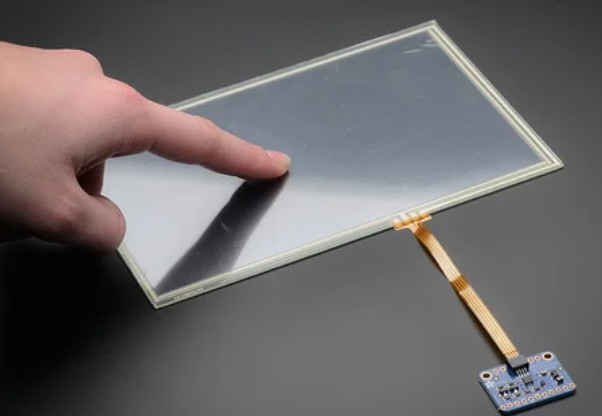

A Resistive Touch Screen uses two transparent conductive layers separated by tiny spacers; when pressure is applied, the layers make contact and the controller calculates the X‑Y position. Because it reacts to pressure, a Resistive Touch Screen works with gloves, stylus, or any object, making it ideal for dirty, wet, or gloved industrial environments.[4][5][2]

- Common structures include 4‑wire, 5‑wire, and 8‑wire Resistive Touch Screen technologies, each optimized for different lifetime and linearity requirements.[2][4]

- Compared with most capacitive designs, a Resistive Touch Screen generally offers better immunity to accidental touches from liquids and can be easier to integrate with existing legacy HMIs.[5][2]

In industrial and medical markets, performance and reliability are more important than consumer‑style gesture control, which is why the Resistive Touch Screen remains a preferred choice. Swiss companies design touch interfaces to withstand vibration, EMI, humidity, and aggressive cleaning agents while maintaining stable calibration over the product lifetime.[3][5][2]

- A Resistive Touch Screen delivers precise single‑point input, which is especially valuable for operators selecting parameters, entering numerical values, or working with tight on‑screen buttons.[4][2]

- Because a Resistive Touch Screen is not dependent on body capacitance, it can be used with different types of gloves, stylus pens, and custom tools, reducing the risk of input errors on production lines.[5][2]

Several Swiss and Switzerland‑based companies supply industrial display and touch solutions; some explicitly produce Resistive Touch Screen panels, while others integrate resistive or capacitive touch into complete HMI systems.[1][2]

- SCHURTER AG – input systems and custom Resistive Touch Screen modules for industrial and medical applications.[2]

- FORTEC Switzerland – industrial display and touch integration specialist, offering TFT modules with resistive or capacitive touch and embedded electronics.[6][1]

- CSC Electronic AG – distributor and project partner for display and touch screen solutions, working closely with Asian factories to deliver custom panels to Swiss customers.[7]

- Fabrimex Systems – Swiss‑made industrial displays and touch systems for harsh environments, including multi‑touch and other HMI solutions.[8][3]

SCHURTER is one of the best‑known Swiss providers of input systems and HMI solutions and offers customized Resistive Touch Screen panels. The company supports 4‑wire, 5‑wire, and 8‑wire Resistive Touch Screen technologies manufactured in state‑of‑the‑art facilities for demanding industrial environments.[2]

- SCHURTER provides complete custom HMI packages, combining Resistive Touch Screen, cover lens, display, and electronics from development to serial production.[2]

- The company offers various surface materials, closed surfaces, and special treatments so a Resistive Touch Screen can meet high hygiene or chemical resistance requirements in medical or food applications.[2]

FORTEC Switzerland focuses on industrial and embedded display solutions and frequently integrates touch technology with TFT and LCD modules. For many projects, FORTEC can supply a Resistive Touch Screen laminated to a display, paired with controller boards and even embedded PCs as one complete solution.[6][1]

- The company emphasizes custom design and manufacturing, from simple custom cables up to complete finished monitors and touch systems.[6]

- FORTEC's approach reduces integration risk: OEMs receive a pre‑validated Resistive Touch Screen plus display package with correct mechanics, optics, and interfaces, shortening time‑to‑market.[1][6]

CSC Electronic AG is a Swiss distributor that specializes in displays and touch screens and works closely with manufacturing partners in China. For OEMs who want flexible sourcing but local support, CSC can coordinate customized Touch Screen solutions, including Resistive Touch Screen panels, via its Asian partners.[7]

- CSC's role includes component selection, engineering coordination, and logistics, which helps smaller OEMs access high‑volume Resistive Touch Screen production capabilities without handling overseas factories directly.[7]

- By centralizing the communication between Swiss customers and Chinese Resistive Touch Screen vendors, CSC helps ensure quality stability and easier after‑sales technical service.[7]

Fabrimex Systems offers industrial display solutions designed for rugged applications and harsh environments. Its portfolio includes robust industrial monitors with touch, often used in automation and transportation systems where reliability is essential.[3]

- A typical Swiss‑made display from Fabrimex provides fast response time, durable housings, and multi‑touch, and similar platforms can also be configured with resistive or capacitive touch according to project needs.[8][3]

- Fabrimex works as a system partner, combining housing, electronics, and touch technology into integrated HMIs so OEMs receive complete units instead of separate Resistive Touch Screen components.[8][3]

Because of the country's strong industrial base, Resistive Touch Screen technology is present in many mission‑critical systems. These sectors demand stable operation in challenging environments, where the durability and pressure‑driven nature of a Resistive Touch Screen provide real advantages.[1][2]

- Process automation and machine tools: operator stations often include a Resistive Touch Screen to ensure accurate input in the presence of oils, metal dust, and vibration.[5][8]

- Transportation, rail, and public infrastructure: control cabinets, station information terminals, and service panels can use a sealed Resistive Touch Screen so staff can operate the system even in bad weather or tight spaces.[5][2]

Swiss medical and laboratory equipment manufacturers integrate Resistive Touch Screen interfaces into analyzers, diagnostic devices, and patient‑related systems. The smooth, closed surfaces available in modern Resistive Touch Screen designs support hygienic cleaning protocols and meet strict regulatory expectations.[2]

- Stylus‑friendly operation allows doctors and technicians to complete detailed forms or mark small elements on the screen using a pen or probe without mis‑touching nearby buttons.[4][2]

- The ability of a Resistive Touch Screen to function under different gloves and in the presence of liquids makes it suitable for wet labs and healthcare environments with frequent disinfection.[5][2]

Although projected capacitive (PCAP) technology is popular for smartphones and modern glass‑front HMIs, the Resistive Touch Screen still offers unique benefits in Swiss industrial and medical projects.[5][2]

| Aspect | Resistive Touch Screen advantage | Capacitive touch advantage |

|---|---|---|

| Input method | Works with gloves, stylus, tools. | Works best with bare or thin‑gloved fingers. |

| Environmental robustness | Less sensitive to liquids and EMI in many designs. | Better multi‑touch and gesture support. |

| Cost and maturity | Mature, cost‑effective technology, easy to qualify. | Premium feel and transparency for modern HMIs. |

Swiss suppliers often offer both technologies, helping customers decide where a Resistive Touch Screen is the optimal choice and where capacitive is more suitable.[1][2]

When choosing a Swiss partner for Resistive Touch Screen projects, buyers should evaluate several key aspects beyond price.[1][2]

- Technology portfolio: confirm whether the supplier can provide 4‑wire, 5‑wire, or 8‑wire Resistive Touch Screen technology, and whether it also offers capacitive options for future upgrades.[4][2]

- Customization and lifecycle: check the supplier's ability to customize cover glass, mechanics, and electronics, and ask about lifecycle management to keep your Resistive Touch Screen design stable for many years.[6][2]

To ensure a smooth development journey, OEMs should prepare a clear technical specification before contacting a Swiss Resistive Touch Screen partner. A good specification allows suppliers to evaluate feasibility and quickly propose the right Resistive Touch Screen structure and integration method.[6][2]

- Define target size, resolution, viewing angle, operating temperature, and required touch technology (Resistive Touch Screen vs capacitive, single‑touch vs multi‑touch).

- Clarify mechanical constraints such as front panel thickness, sealing level (for example IP65), chemical exposure, and the type of gloves or tools that will operate the Resistive Touch Screen.[2]

International OEMs can collaborate with Swiss Resistive Touch Screen and HMI suppliers through different cooperation models.[6][1]

- Direct engineering cooperation: for higher‑volume or strategic projects, OEMs may work directly with SCHURTER, FORTEC, or Fabrimex to co‑develop a custom Resistive Touch Screen module integrated into an HMI front panel.[6][2]

- Local distributor route: smaller and mid‑sized customers may prefer to work via a distributor such as CSC Electronic AG, which coordinates customized Resistive Touch Screen sourcing and local logistics.[8][7]

Swiss manufacturers and integrators attach great importance to quality and compliance testing for any Resistive Touch Screen or HMI system they deliver. That focus is important for sectors such as medical, railway, and industrial automation where product failure can be costly or dangerous.[3][5][2]

- Typical testing for a Resistive Touch Screen includes durability (number of actuations), linearity, environmental and temperature cycling, shock and vibration, and EMC compliance at the module or system level.[4][2]

- Many Swiss suppliers are familiar with international standards and can support documentation for CE, UL, railway, or medical approvals where a Resistive Touch Screen forms part of a certified device.[3][2]

As a professional Chinese manufacturer of abrasives and refractory materials, your company can collaborate with Swiss HMI and Resistive Touch Screen suppliers to build complete solutions for end‑users. This combination strengthens your position as a full‑solution partner rather than a simple material provider.[1]

- Joint marketing: combine grinding, cutting, or polishing solutions with Swiss control panels featuring Resistive Touch Screen interfaces to promote “process + HMI” packages for global machinery clients.[1]

- Co‑engineering: cooperate with a Swiss HMI partner so that new grinding or polishing machines include a customized Resistive Touch Screen panel for recipe management, process monitoring, data logging, and remote diagnostics.[6][2]

On your English website, you can enrich the article and improve user engagement by pairing the text with visual content demonstrating Resistive Touch Screen advantages. Visual storytelling also makes Swiss partnerships and real‑world applications more convincing to potential buyers.[5][2]

- Include photos of industrial panels, medical devices, and control cabinets where a Resistive Touch Screen is clearly visible and being operated with gloves or stylus.

- Publish short videos showing Resistive Touch Screen testing (for example durability or water‑drop tests) and simple user tutorials that highlight responsiveness and reliability in harsh settings.[5][2]

Switzerland has developed a focused ecosystem of manufacturers, integrators, and distributors supporting industrial display and touch solutions, including high‑quality Resistive Touch Screen technology. By working with companies such as SCHURTER, FORTEC Switzerland, CSC Electronic AG, and Fabrimex Systems, global OEMs and system integrators can secure robust, glove‑friendly Resistive Touch Screen interfaces tailored to demanding industrial and medical environments.[3][1][2]

A Resistive Touch Screen is a pressure‑sensitive panel made of two conductive layers separated by tiny spacers; touch input occurs when the layers contact and the controller reads the coordinates. In Switzerland, it remains popular in industrial and medical HMIs because it works with gloves, stylus, and under harsh conditions where optical or capacitive solutions may be less stable.[4][2][5]

SCHURTER specifically offers customized Resistive Touch Screen panels and complete HMI systems, while FORTEC Switzerland and Fabrimex integrate touch technology into industrial displays and monitors. CSC Electronic AG acts as a sourcing partner, coordinating custom touch screen solutions from manufacturing partners in China and supplying them to Swiss OEMs.[7][3][1][2]

Swiss suppliers can tailor the Resistive Touch Screen size, aspect ratio, surface material, and graphics, and they can laminate the sensor to a specific TFT module with matching controller boards. Many also adjust optical bonding, sealing, and housings so the Resistive Touch Screen module meets IP, hygiene, or EMC requirements in your target application.[3][1][2]

Yes, most Swiss display and HMI suppliers support both resistive and capacitive technologies, allowing you to choose a Resistive Touch Screen for harsh environments and capacitive for modern glass‑front HMIs. This mixed portfolio helps OEMs standardize mechanics while selecting the best touch technology per usage scenario.[1][2][5]

Overseas OEMs typically begin by sharing project details—environment, required size, interface, and expected lifetime—so the supplier can recommend a suitable Resistive Touch Screen solution. After prototype approval, the Swiss partner will define pricing, lead times, and lifecycle support to ensure stable serial supply and consistent quality.[2][6]

[1](https://www.fortec.ch/en/Products/Displays/)

[2](https://www.schurter.com/en/products-and-solutions/input-systems/resistive-touchscreens)

[3](https://www.fabrimex-systems.ch/en/12-display-solutions)

[4](https://crystal-display.com/products/analogue-resistive-touch/)

[5](https://www.esa-automation.com/en/6-fundamental-features-in-a-panel-pc-2/)

[6](https://www.fortec.ch/en/Services/Design-Manufacture/)

[7](https://www.csc.ch/en/manufacturer-focus/)

[8](https://www.bsaswiss.ch/en/industrial-automation/)

Top Resistive Touch Screen Manufacturers and Suppliers in Turkey

Top Resistive Touch Screen Manufacturers and Suppliers in Vietnam

Top Resistive Touch Screen Manufacturers and Suppliers in South Korea

Top Resistive Touch Screen Manufacturers and Suppliers in Japan

Top Resistive Touch Screen Manufacturers and Suppliers in Italy

Top Resistive Touch Screen Manufacturers and Suppliers in Portugal

Top Resistive Touch Screen Manufacturers and Suppliers in Spain