Views: 222 Author: Wendy Publish Time: 2025-12-20 Origin: Site

Content Menu

● Overview of Resistive Touch Screen Technology

● Why Source from UK Suppliers?

● Key UK Resistive Touch Screen Manufacturers and Suppliers

>> FORTEC UK

>> UDISYS

>> Nemacom Ltd

>> Distributor and Component Channels (Farnell, RS)

● Typical Applications in the UK Market

● Environmental and Regulatory Considerations

● Practical Selection Tips for Resistive Touch Screen Projects

● Cooperation Steps with UK Suppliers

● Recommended Use of Resistive vs PCAP in UK

● Lifecycle Management and After‑Sales Service

● FAQ

>> 1. What is a Resistive Touch Screen and how does it work?

>> 2. When should I choose a Resistive Touch Screen instead of capacitive?

>> 3. Can UK suppliers customize the size and shape of a Resistive Touch Screen?

>> 4. Do UK manufacturers support long‑term supply for industrial Resistive Touch Screen projects?

>> 5. How can overseas buyers evaluate UK Resistive Touch Screen suppliers remotely?

The UK has a mature ecosystem of industrial display and HMI companies that can supply, customize, and integrate Resistive Touch Screen solutions for automation, medical, marine, transportation, and kiosk projects. For overseas OEMs and system integrators, UK Resistive Touch Screen manufacturers and suppliers combine engineering expertise, strong quality control, and convenient logistics into Europe.[1][2][3][4]

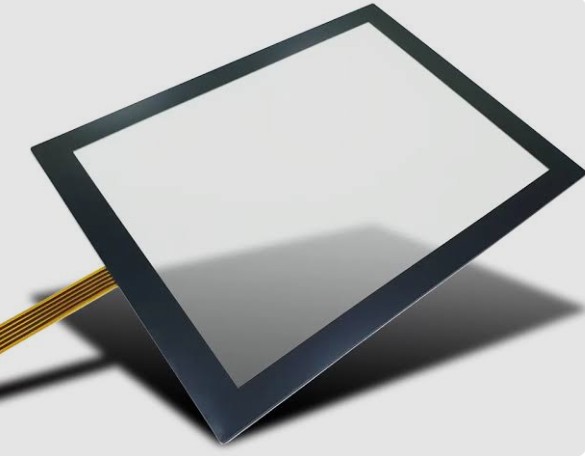

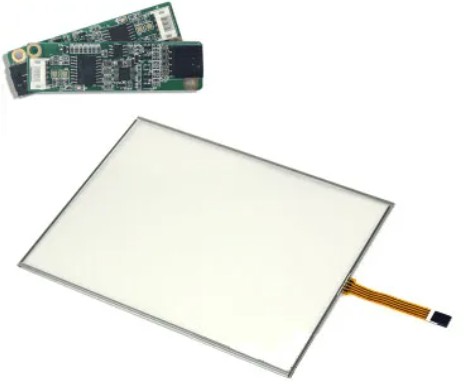

Resistive Touch Screen technology uses pressure from a finger, glove, or stylus to register input, making it ideal for harsh or contaminated environments where capacitive touch may struggle. A Resistive Touch Screen typically consists of two flexible conductive layers with a small air or spacer gap; when pressed, the layers make contact and the controller interprets the touch position.[5]

- Works with gloves, stylus, or any pointing object.

- Less sensitive to water, dust, and electromagnetic noise than many PCAP solutions.

In industrial HMIs and embedded systems, a Resistive Touch Screen remains popular because it is cost‑effective, simple to drive, and available in many standard and custom sizes, including 4‑wire and 5‑wire versions.[2][1]

UK Resistive Touch Screen suppliers are attractive to European and global buyers because they offer local design support, ISO‑certified processes, and strong after‑sales service. Many UK companies integrate the Resistive Touch Screen with TFT panels, enclosures, cables, and controllers, delivering complete, ready‑to‑mount assemblies.[3][4][1][2]

- Shorter lead times into Europe compared with intercontinental shipping.

- Easier communication, engineering review, and compliance with European standards.

For buyers who need a reliable Resistive Touch Screen plus industrial enclosure, panel PC, or full HMI station, UK manufacturers can provide turnkey solutions under a single warranty and support structure.[6][3]

FORTEC UK offers 4‑wire and 5‑wire Resistive Touch Screen technologies across multiple stocked sizes from around 5.7 inches up to 24 inches and beyond. The company also provides custom display and touch assemblies, including custom cables, mechanical design, and electronic design for bespoke TFT and Resistive Touch Screen solutions.[4][1]

- ISO9001‑certified design and manufacture, including drawing revisions and formal product change notifications.

- Ability to modify and adapt custom touch screens quickly, which is ideal for long‑life industrial Resistive Touch Screen projects.[4]

A typical project with FORTEC might combine an industrial TFT panel, resistive sensor, cover lens, and housing, giving integrators a drop‑in Resistive Touch Screen module tailored to their panel cut‑out and environmental requirements.[1][4]

UDISYS is a UK‑based provider supporting both resistive and capacitive touchscreens and can help customers choose between a Resistive Touch Screen and PCAP for their application. The company offers standard and customized products, including industrial touch displays, HMI solutions, and integrated systems for OEM and retrofit markets.[7]

- Engineering support to select the optimum Resistive Touch Screen size and controller.

- Ability to tailor touch solutions around existing mechanical designs or retrofit projects with minimal redesign.[7]

For OEMs upgrading legacy equipment that previously used a Resistive Touch Screen, UDISYS can propose equivalent or improved resistive panels with modern controllers, extended temperature ranges, and better optical performance.[7]

GSR Technology in the UK supplies industrial TFT monitors and Resistive Touch Monitors as enclosed, ready‑to‑use units suitable for various industrial and commercial environments. These monitors are configured display solutions that allow buyers to deploy a Resistive Touch Screen without designing their own enclosure or integration hardware.[2]

- Range of industrial TFT monitors with integrated resistive touch, front panels, and mounting options such as panel‑mount and VESA.

- Focus on ruggedness and continuous use in harsh industrial environments where a Resistive Touch Screen must work reliably 24/7.[2]

GSR Technology is a good choice for integrators who prefer to mount complete Resistive Touch Screen monitors rather than bare sensors plus LCD combinations, helping reduce engineering effort and certification risks.[2]

Nemacom Ltd is a UK manufacturer of industrial display solutions, including panel PCs, rugged touchscreen displays, and interactive kiosks for demanding sites. The company supports both Resistive Touch Screen and PCAP technologies depending on application needs and offers UK‑built and supported products with an industry‑leading five‑year warranty on many systems.[3][5]

- Over 30 years of experience in industrial touch and display markets with a strong installed base.

- Expertise in matching Resistive Touch Screen or PCAP to the software, environment, and operator preferences of a project.[5][3]

For demanding industrial sites where single‑touch operation with gloves is sufficient, Nemacom can specify a Resistive Touch Screen front end for panel PCs or displays, combining it with stainless‑steel or powder‑coated enclosures to meet hygiene or corrosion‑resistance requirements.[3][5]

Direct Insight focuses on embedded systems and offers resistive and capacitive touch display solutions integrated with ARM‑based system‑on‑modules and single‑board computers. The company aims to support a broad range of touch screens and can recommend appropriate Resistive Touch Screen or capacitive options for customer‑specific embedded solutions.[8]

- Can support many third‑party TFT displays with resistive or capacitive touch via RGB, LVDS, HDMI, MIPI‑DSI, or DisplayPort interfaces.

- Development boards that ship with resistive and capacitive touch “out of the box,” enabling rapid prototyping of HMI applications.[8]

For embedded OEMs, Direct Insight offers a strong combination of Resistive Touch Screen hardware, carrier boards, and operating system support, simplifying the design of compact HMI terminals.[8]

Large distributors such as Farnell in the UK stock analogue Resistive Touch Screens, along with controllers and cabling, giving engineers access to off‑the‑shelf parts for small to medium runs and maintenance. RS Components also offers HMI displays and touch panels from well‑known global brands, supporting both resistive and capacitive technologies.[9][10]

- Fast quotes, same‑day dispatch, and technical support for Resistive Touch Screen parts during design and repair.

- Broad inventory, which helps during prototyping, field service, and smaller‑volume projects that do not justify full custom tooling.[10][9]

For companies that need only the Resistive Touch Screen sensor or controller for a custom mechanical design, distributors provide a convenient, lower‑risk supply route with predictable lead times and stable part numbers.[9][10]

A Resistive Touch Screen is widely used in UK industrial, commercial, and medical environments where durability and predictable operation are more important than multi‑touch gestures or advanced UI effects. Local manufacturers and suppliers frequently design Resistive Touch Screen HMIs for factory automation, marine navigation, process control, and rugged kiosks.[11][5][2]

Key application areas include:

- Factory automation: PLC operator panels, machine controllers, and robotics HMIs, where operators wear gloves and need reliable single‑touch input.

- Kiosks, ticketing machines, and POS terminals that must operate reliably in public areas, sometimes outdoors or under variable lighting.[12][11][2]

In environments with dust, moisture, vibration, or chemicals, a Resistive Touch Screen can be combined with sealed bezels, IP65/IP66 front panels, and rugged housings to guarantee long‑term reliability and easy cleaning.[11][3]

When deploying a Resistive Touch Screen in UK and European markets, compliance with relevant safety and EMC standards is crucial. Many UK manufacturers already design Resistive Touch Screen assemblies and monitors to meet CE, UKCA, and often additional industry‑specific standards.[6][3]

- Industrial HMIs may need EN‑based EMC, vibration, and temperature testing to ensure the Resistive Touch Screen remains stable in real use.

- Sectors like medical and transportation often require extra documentation and traceability for Resistive Touch Screen components and materials.[11][3]

Working with UK suppliers familiar with these frameworks reduces certification risk and shortens time to market for equipment using a Resistive Touch Screen front end.[6][3]

Choosing the right Resistive Touch Screen solution from UK manufacturers requires attention to key technical and commercial factors that influence long‑term performance.

Important technical criteria:

- Screen size, resolution, and aspect ratio matching existing hardware, enclosures, and operator viewing distance.

- Touch technology (4‑wire versus 5‑wire Resistive Touch Screen) depending on required durability, calibration stability, and lifetime.[13][1]

Equally important commercial aspects:

- Availability of long‑term supply and revision control to avoid frequent redesigns when a Resistive Touch Screen component changes.

- Warranty, repair turnaround, and local technical support, especially for 24/7 industrial applications using a Resistive Touch Screen interface.[4][3][6][11]

By aligning these criteria with project requirements, buyers can secure a stable Resistive Touch Screen platform that supports product lifecycles spanning many years.[4][11]

A structured cooperation process helps international buyers and UK Resistive Touch Screen suppliers achieve successful HMI projects with predictable cost and schedule.

Typical cooperation steps:

- Early engineering consultation to define screen size, brightness, operating temperature, interface type, and Resistive Touch Screen technology.

- Prototype build and testing, often using stock displays combined with custom resistive overlays before committing to full tooling and certifications.[1][2][4]

After validation, UK manufacturers can finalize custom drawings, confirm revision control processes, define packaging, and plan regular shipments of Resistive Touch Screen modules or monitors to match the OEM's production schedule.[3][6][4]

UK suppliers commonly help customers choose between a Resistive Touch Screen and projected capacitive (PCAP) depending on operating conditions, budget, and the expected user interface style.[5][7]

Resistive is often recommended when:

- Operators wear thick gloves, hold tools, or need stylus‑level precision without relying on special capacitive gloves.

- The environment involves dust, oils, cleaning chemicals, or electromagnetic noise that could affect PCAP sensors.[5][11]

In contrast, PCAP may be chosen when multi‑touch gestures, edge‑to‑edge glass aesthetics, or smartphone‑like user experiences are priorities. Many UK companies offer both options and can design platforms that allow swapping between a Resistive Touch Screen and PCAP with minimal mechanical change.[3][5]

Industrial users expect a Resistive Touch Screen to remain available and supportable for many years, often longer than consumer technologies. UK manufacturers typically adopt lifecycle management practices that address this requirement.[6][11][3]

- Long‑term component sourcing, alternative component validation, and controlled product changes for Resistive Touch Screen assemblies.

- After‑sales services such as repair, refurbishment, and on‑site support for deployed Resistive Touch Screen monitors and panel PCs.[6][3]

These practices allow OEMs and integrators to standardize on a specific Resistive Touch Screen platform without frequent redesigns, which is critical for regulated and safety‑critical sectors.[3][6]

The UK offers a diverse group of manufacturers, system integrators, and distributors capable of delivering robust Resistive Touch Screen solutions for industrial, commercial, and embedded markets. By working with established UK suppliers such as FORTEC UK, UDISYS, GSR Technology, Nemacom, Direct Insight, and major distributors, global buyers can source reliable Resistive Touch Screen panels, monitors, and HMI systems with strong technical support, lifecycle management, and compliance with European standards.[9][1][7][8][11][2][4][5][6][3]

A Resistive Touch Screen is a pressure‑sensitive touch interface consisting of two conductive layers separated by a small gap; when pressed, the layers make contact, allowing the controller to calculate the touch position. Because it relies on pressure rather than body capacitance, a Resistive Touch Screen can be activated with fingers, gloved hands, stylus pens, or almost any object.[5]

A Resistive Touch Screen is ideal when the environment involves gloves, tools, or contaminants that may interfere with capacitive sensing, and when only single‑touch input is required. In many industrial, medical, and outdoor applications in the UK, Resistive Touch Screen HMIs deliver predictable performance under dust, moisture, and EMI that might cause issues for PCAP panels.[11][5]

Many UK suppliers can customize Resistive Touch Screen designs, including size, cover glass, printing, bonding, and connector layout to match existing panel cut‑outs and brand styling. Companies such as FORTEC UK and Nemacom offer bespoke mechanical and electronic design services, enabling fully custom resistive HMI assemblies that align with project‑specific mechanical envelopes.[1][4][3]

UK manufacturers and distributors typically focus on long‑term availability, revision control, and lifecycle management for industrial displays and Resistive Touch Screen products. Firms like Nemacom and Hope Industrial Systems combine extended warranties, industrial‑grade components, and controlled change processes to support equipment lifecycles spanning many years.[11][6][3]

Overseas buyers can review datasheets, certifications, application photos, and demonstration videos to understand product quality and real‑world usage of a Resistive Touch Screen solution. Many UK suppliers also provide engineering consultations, remote testing support, and sample shipments, making it straightforward to qualify a Resistive Touch Screen design before mass deployment and to compare multiple suppliers objectively.[8][4][11][3]

[1](https://www.fortec.uk/Products/Touch-Screen-Components/Resistive-Touch-Screen/)

[2](https://gsr-technology.co.uk/product-category/monitor-solutions/resistive-touch-monitors/)

[3](https://www.nemacom.co.uk)

[4](https://www.fortec.uk/Services/Design-Manufacture/)

[5](https://www.nemacom.co.uk/resistive-pcap-touch-screen-difference/)

[6](https://hopeindustrial.co.uk)

[7](https://udisys.co.uk/touchscreens/)

[8](https://www.directinsight.co.uk/touch-screen-displays/)

[9](https://uk.farnell.com/c/automation-process-control/panel-displays-instrumentation/human-machine-interface-hmi/touch-screens?meter-display-type=analogue-resistive)

[10](https://uk.rs-online.com/web/c/automation-control-gear/plcs-hmis-industrial-computing/hmi-displays/?pn=5)

[11](https://www.beetronics.co.uk/c-industrial)

[12](https://www.diamondhmi.co.uk/products/lcd-tft-displays/)

[13](https://www.elotouch.co.uk/touchscreen-components-accutouch-5-wire-resistive-bezel.html)

Top Resistive Touch Screen Manufacturers and Suppliers in Turkey

Top Resistive Touch Screen Manufacturers and Suppliers in Vietnam

Top Resistive Touch Screen Manufacturers and Suppliers in South Korea

Top Resistive Touch Screen Manufacturers and Suppliers in Japan

Top Resistive Touch Screen Manufacturers and Suppliers in Italy

Top Resistive Touch Screen Manufacturers and Suppliers in Portugal

Top Resistive Touch Screen Manufacturers and Suppliers in Spain